Low temperature lab

Introduction to Low Temperature Hydrogen and Fuel Cell Lab

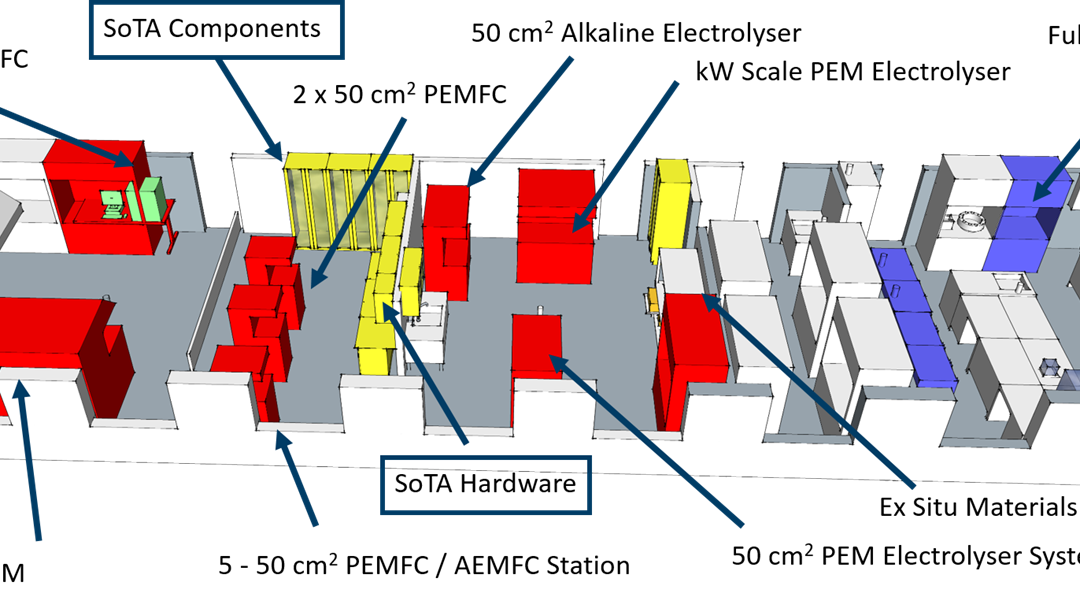

The low temperature lab is fully equipped to test fuel cells and electrolysers that operate below 110 oC. The test stations in the lab are suitable for carrying out tests on cutting edge materials and components (mW single cell testing) right through to validating the performance and durability of established technologies (kW short stack testing). As well as these state-of-the-art test stations the lab has access to high quality commercial components, test hardware and has very experienced SINTEF staff on hand.

The lab is located in Trondheim on the Gløshaugen Campus and is conveniently co-located with the world-class materials characterisation facilities of NTNU.

Fuel Cell Test Stations

2 x G60 PEM FC Stations

The two G60 test stations are designed for testing single cells up to 50 cm2 under a full range of operating conditions. They can be coupled with a potentiostat and frequency response analyser they are ideal for characterising new fuel cell components and performing advanced in situ measurements. With fully automated testing these twin test stations are also excellent at long term and accelerated stress testing of components.

| Property | Indicative Range |

| Max Current | 125 A |

| Voltage Monitoring | ± 1 mV |

| Data Logging Rate | 10 Hz |

| PSTAT/FRA | Integration with Biologic |

| Coolant Temp | -5 - 90 oC ± 1 oC |

| Coolant Pressure | 0 - 3 barg ± 0.02 bar |

| Electrical Heaters | 2A 240VAC |

| Anode | |

| Gasses | Nitrogen (5N), Hydrogen (5N) |

| Flow Rate | 0.01 - 1, 0.03 - 3 NLPM |

| Dew Point | -5 - 90 oC ± 1 oC |

| Pressure | 0 - 3 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

| Cathode | |

| Gasses | Air, Oxygen (5N), Nitrogen (5N) |

| Flow Rate | 0.12 - 12, 0.12 - 12, 0.01 - 1 NLPM |

| Dew Point | 20 - 90 oC ± 1 oC |

| Pressure | 0 - 3 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

G400 Test Station

This 12 kW fuel cell test station is ideally suited for advanced characterisation of short stack fuel cells. It is fully automated and can be integrated with a potentiostat and FRA for advanced cell and stack characterisation. The test station is specially equipped to operate with both a recirculating and dead-ended anode and has rapid response humidifiers allowing rapid changes (<10 s) in humidity.

| Property | Indicative Range |

| Max Current | 800A |

| Max Voltage | 80V |

| Max Power | 10 kW |

| Voltage Monitoring | 40 Channels ± 1 mV |

| Data Logging Rate | Upto 100 Hz |

| PSTAT/FRA | Integration with Biologic |

| Coolant Temp | 30 - 90 oC ± 1 oC |

| Coolant Pressure | 0.05 - 3 barg ± 0.02 bar |

| Coolant Flow | 2 - 25 LPM ± 1% |

| Coolant Restivity Meter | 0.01 - 100 μS cm-1 |

| Anode | |

| Gasses | Nitrogen (5N), Hydrogen (5N) |

| Flow Rate | 4 - 300, 1 - 30 & 5 - 300 NLPM |

| Dew Point | 30 - 90 oC ± 1 oC |

| Pressure | 0 - 3 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

| Cathode | |

| Gasses | Nitrogen (5N), Air (filtered) |

| Flow Rate | 4 - 300, 2-75 & 5 - 750 NLPM |

| Dew Point | -5 - 90 oC ± 1 oC |

| Pressure | 0 - 3 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

G40 Fuel Cell Station

The G40 fuel cell test station is ideally suited for initial in situ testing of experimental materials and components. It is regularly used for experiments on anion exchange membrane fuel cells. It is capable of testing 5 - 25 cm2 cells across a full range of operating conditions and of fully automatic operation. It is integrated with a potentiostat and FRA for advanced in situ characterisation.

| Property | Indicative Range |

| Max Current | 60 A |

| Voltage Monitoring | ± 1 mV |

| Data Logging Rate | 10 Hz |

| PSTAT/FRA | Gamry Ref3000 |

| Electrical Heaters | 2A 240VAC |

| Anode | |

| Gasses | Nitrogen (5N), Hydrogen (5N) |

| Flow Rate | 0 - 4 , 0 - 2 NLPM |

| Dew Point | 40 - 90 oC ± 1 oC |

| Pressure | 0 - 2 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

| Cathode | |

| Gasses | Air, Oxygen (5N), Nitrogen (5N) |

| Flow Rate | 0 - 4, 0 - 4, 0 - 1 NLPM |

| Dew Point | 40 - 90 oC ± 1 oC |

| Pressure | 0 - 2 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

G20 Direct Methanol & PEM Station

This G20 test station is designed for testing DMFC and PEMFC cells up to 20 cm2. It is fully automated and integrated with a Gamry Ref600 for EIS and voltammetry. It is ideally suited for testing new catalysts for alcohol oxidation.

| Property | Indicative Range |

| Max Current | 30 A |

| Voltage Monitoring | ± 1 mV |

| Data Logging Rate | 10 Hz |

| PSTAT/FRA | Integration with Gamry Ref600 |

| Electrical Heaters | 2A 240VAC |

| Hydrogen Anode | |

| Gasses | Nitrogen (5N), Hydrogen (5N) |

| Flow Rate | 0 - 1, 0 - 3 NLPM |

| Dew Point | 40 - 90 oC ± 1 oC |

| Pressure | 0 - 3 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

| Methanol Anode | |

| Flow Rate | 0 - 1 LPM |

| Pressure | 0 - 3 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

| Cathode | |

| Gasses | Air, Oxygen (5N), Nitrogen (5N) |

| Flow Rate | 0 - 3, 0 - 3, 0 - 1 NLPM |

| Dew Point | 40 - 90 oC ± 1 oC |

| Pressure | 0 - 3 barg ± 0.02 bar |

| Inlet Temp | 40 - 110 oC ± 1 oC |

Electrolyser Test Stations

E100 Station

The E100 test station is perfect for testing small electrolyser stacks. It is fully automated and integrated with a potentiostat and FRA for advanced characterisation and long term accelerated stress testing. It has independent anode and cathode loops, able to operate in differential pressure mode up to 30 bar.

| Property | Indicative Range |

| Current | 500A |

| Voltage | 20VDC |

| Power | 10 kW |

| Cell Voltage Monitoring | 10 Channels ± 1 mV |

| Data Logging | 100 Hz |

| Purification | Coalescing and dessicant filter |

| Anode Air Supply | |

| Flow rate | 0.2 -20 NPLM |

| Dew Point | 35-90 oC ± 1 |

| Pressure | 0-5 barg ± 0.02 bar |

| Make up water | 100 ml min-1 |

| Anode and Cathode Water Supply | |

| Independent anode and cathode. | |

| Recirculation Flow | 0.6-6 NLPM |

| Flow Measurment | ± 1% |

| Pressure | 0 - 29 barg |

| Conducitivity Meters | 0.04 - 20 μS cm-1 |

| Temperature Control | 5 - 95 oC ± 1 oC |

| Anode | |

| Mass Flow Meter | 0-40 NLPM |

| H2 in O2 Analyser | 0-5% |

| Cathode | |

| Mass Flow Meter | 0.36 - 32 NLPM |

Alkaline Electrolyser Station

This one of a kind single alkaline cell test station is capable of testing both Alkaline Electrolysers and Alkaline Membrane Electrolysers under differential pressure operation up to 20 bar and with KOH concentrations from 0 to 30%.

| Property | Indicative Range |

| Current | 100A |

| Voltage | 8V |

| Max Power | 800W |

| Voltage Monitoring | 1 channel ± 1 mV |

| Data Logging | 100 Hz |

| PSTAT/EIS | Integrated with Biologic |

| Gas Control | |

| Pressure control is independent anode and cathode. | |

| Pressure Control | 1 - 29 barg |

| Gas Purification | Coalescing, condensate and dessicant filters. |

| Cathode H2 meter | 0 - 5 NLPM |

| Anode O2 meter | 0 - 4 NLPM |

| Anode Gas Analyser | 0 - 5% H2 in O2 |

| Electrolyte Supply | |

| Anode and cathode flows are remixed | |

| Inlet Temperature | 15 - 90oC ± 1 oC |

| Conductivity Meter | 0 - 2 S cm-1 |

| Flow rate | 37.5 mLPM on each side |

E60 Test Station

The E60 test station is ideal for testing PEM electrolysers from 25 - 50 cm2 under a full range of operating conditions. It is ideal for characterising new electrolyser materials and components. With fully automated testing this test stations are also excellent at long term and accelerated stress testing of components.

| Property | Indicative Range |

| Max Current | 100 A |

| Voltage Monitoring | ± 1 mV |

| Data Logging Rate | 10 Hz |

| Anode and Cathode Water Supply | |

| Anode and cathode operate independently. | |

| Temp | 25 - 90 oC ± 1 oC |

| Pressure | 0 - 29 barg |

| Flow Rate | 0 - 5 LPM |

| Conductivity Sensor | 0.04 - 20 μS cm-1 |

| Gas Analysis | |

| Anode Mas Flow Meter | 0-4 NLPM |

| Cathode Gas Flow Mater | 0-5 NLPM |

| H2 in O2 Analyser | 5% |

Ancillary Equipment

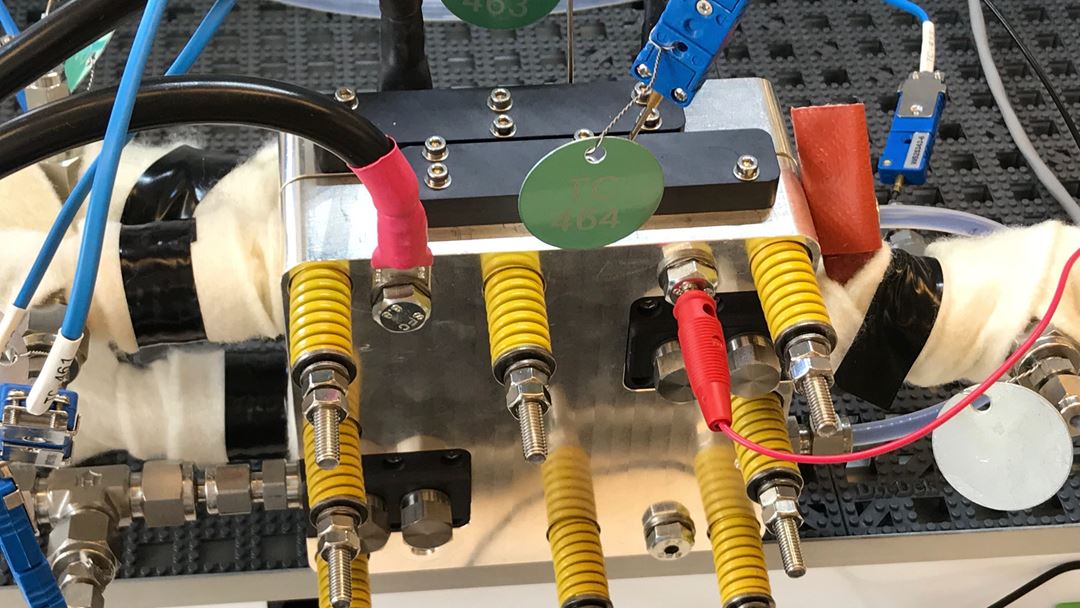

Cell Hardware & Components

In addition to the fuel cell and electrolyser testing station the lab has access to a range of state of the art commercial components and cell hardware. This is essential for obtaining high quality baseline data and for building cells with one experimental component.

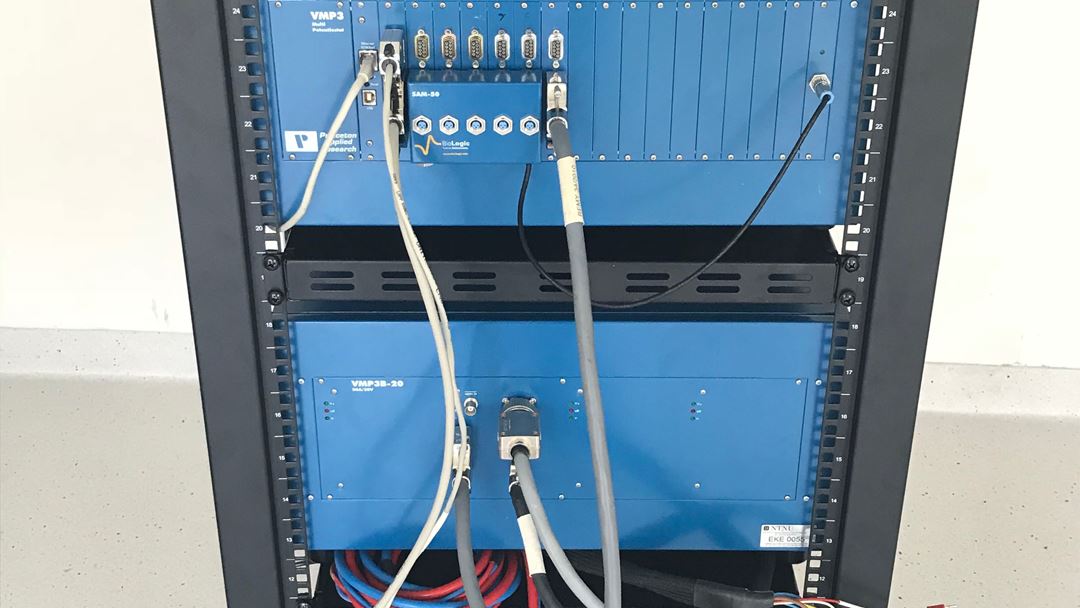

Potentiostats & Data Loggers

The lab contains a range of potentiostats that can be fully integrated into fuel cell and electrolyser test stations for both cycling voltammetry, impedance and more advanced characterisation techniques.

- Gamry Ref3000

- Gamry Ref600

- 3 x Biologic VMP3 multi-channel Potentiostats

- 2 x 20A Biologic Boosters

- 1 x 50A Biologic Boosters

- Aglient 34970A Multiplexer and Multimeter