WP5: Seedling, deployment and harvest technology (SINTEF Ocean, Industry partners)

Existing processes and methods for seedling production and seeding of substrates have been reviewed with regard to industrial scale production.

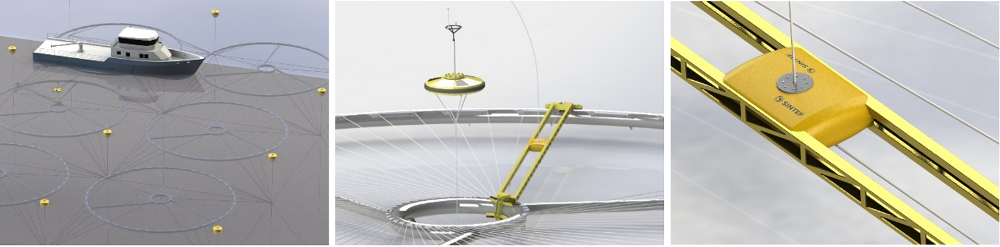

A lab system has been designed for automatic seedling production, allowing the seedlings to be grown in monitored, optimal conditions. An industrial production line for seedlings has been assessed and outlined based on state of the art for such systems. Methods for image processing of substrate for quantification of sporophytes and spore density have been developed enabling processing of many images with little effort, compared to manual counting. A prototype for preparation of substrate-spools has been made, spinning 300m of substrate line on two plastic cylinders in 90 sec. A machine referred to as a "seaweed spinner" has been developed to automate the wrapping of substrate line around a carrier rope before deployment at sea. Spools of seeded twine are loaded into the machine and rotated around the rope at a processing speed of 110m carrying rope in 14min. A design study targeting automation and standardization of kelp cultivation (SPOKe) has been performed. The concept encompasses circular modules to allow for an easy platform for automation. A gantry robot on rails is used to interact with the modules, equipped with tools depending on its task. A VR demo and a prototype, demonstrating the principle for control of the gantry robot are available for display at SINTEF Ocean.

Figure: Machines for spinning of seedling strings (left and right), and test result (middle) We also propose a concept for Standardized Production of Kelp (SPOKe), a module-based design of circular production units, with a specialized robotic rail for automation of deployment and harvesting operations (Figure below).

Figure: Standardized Production of Kelp (SPOKe)

Status autumn 2017 (EN)

Seedling, deployment and harvesting technology (WP5):

Adaptations to next generation seaweed rope spinner (designed at SINTEF with the Mtech company as subcontractor) for in situ use in deployment are being studied. The seeding time/speed (meter seeded rope per day) has been increased 6-10 times in MACROSEA. Design and evaluation of a new production concept for large scale production have resulted in a design study of the MACROSEA eSpoke seaweed farm concept (see movie on www.macrosea.no) planned for a fully automated deployment and harvest operation. We have developed image analysis methods for effective counting of gametophytes on seeded material before deployment.

Workshops

A workshop on seaweed production technology (WP5 and WP6) with contributions from seaweed producers, equipment manufacturers and R&D institutes was arranged at SINTEF Sealab in Trondheim in September 2017, and