|

Application technology

Both Helicopter and vessel application of dispersants are considered to have a significant potential in ice-covered waters. Through an evaluation of the different dispersant spray systems and platforms it has been recommended to focus the further work within this task on vessel as application.

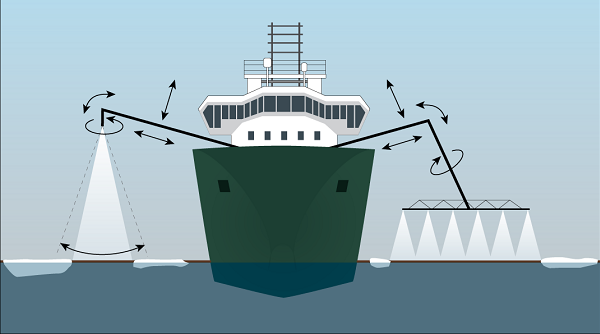

In cooperation with the ARTEC program (“Next generation oil spill technology for Arctic and ice covered waters”) funded by the oils companies and the Norwegian Research Council, a prototype of a new boat spraying system for optimising application of dispersant under Arctic conditions are under construction. The system will allow more flexible application between ice floes, be easily transportable, protected from icing (containerized), based on manoeuvrable hydraulic spraying arms and can be operated from a wide range of vessels. The first version of prototype is planned to be tested in the 2009 field trials in MIZ Barents Sea.

For further information regarding dispersant application, contact; or

|

| |

The

The