- Name

- M.Sc. Vinzenz Müller

- Title

- Organization

- Fraunhofer IPK

Fraunhofer IPK

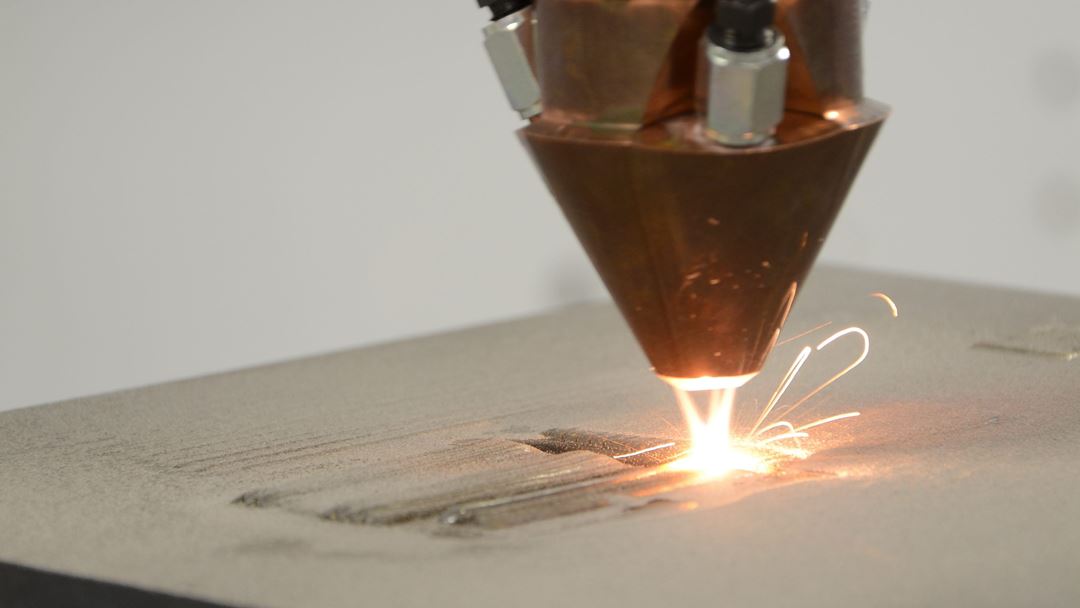

The interdisciplinary Additive Manufacturing team in Fraunhofer IPK is specialized in the metalworking processes: Laser Powder Bed Fusion (L-PBF) and Directed Energy Deposition (DED). In the FlexiMan project, Fraunhofer IPK is developing manufacturing strategies for complex DED-parts such as propeller blades and pump impellers.

Our interdisciplinary Additive Manufacturing team is specialized in the metalworking processes Laser Powder Bed Fusion (L-PBF) and Directed Energy Deposition (DED). Among other things, we offer economical manufacturing solutions for the latest tool concepts, develop customized repair processes and shorten time-to-market by using simulation tools. The development of new machine concepts for AM to increase the product quality and manufacturing robustness of our customers is another core topic.

In the FlexiMan project, Fraunhofer IPK is developing manufacturing strategies for complex DED-parts such as propeller blades and pump impellers. In this context, the workflow of virtual component creation in CAD/CAM and process simulation are key tasks. Further investigations will be carried out in the design of up-cycling chains for metal waste from grinding processes. These resources are promising to become a sustainable resource for new AM raw material powder.

Visit: https://www.ipk.fraunhofer.de/en.html