Thermoelectric oxides

Thermoelectric oxides

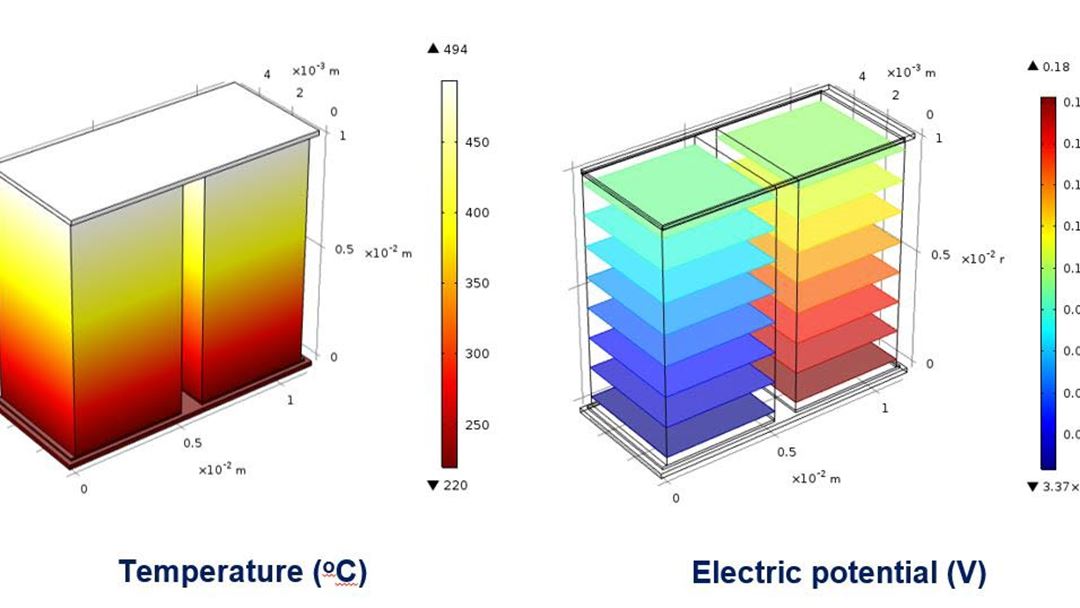

A thermoelectric generator (TEG) consists of a number of p-type and n-type thermoelements connected alternately electrically in series and thermally in parallel. A temperature difference between hot and cold ends of the TEG produces a voltage via the Seebeck effect.

State-of-the-art thermoelectric conductor materials are mainly based on non-oxide semi-conductors (e.g. chalcogenides with Te, Bi and Pb) and intermetallics (e.g. ZnSb type). However, there are challenges associated with high cost due to the need for nano-structuring, and limited operating temperature range.

Oxide materials offer higher resistance to corrosion and evaporation, are less expensive and more stable at high temperature. Far fewer oxides have been studied so far compared to non-oxide materials and lower efficiencies are reported.

To improve the oxide thermoelectrics, SINTEF uses computational modelling to define the most promising materials systems and develops experimental procedures and tools to measure TEG performance.

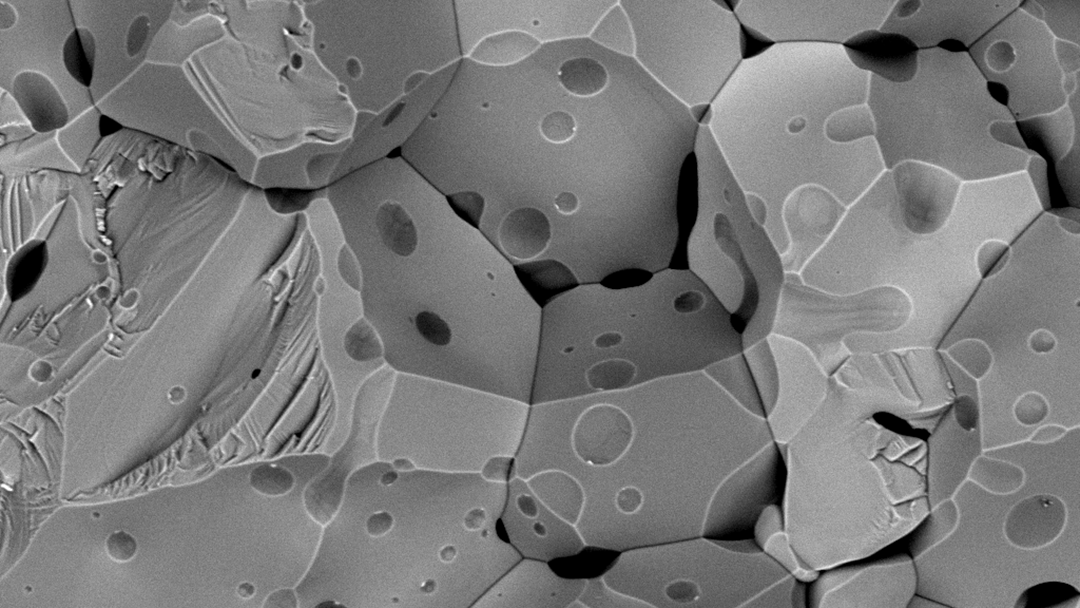

OXIPATH has identified Ni-Li-O and Zn-Al-O as two materials systems of particular interest. We are currently making samples with a variety of compositions within these systems and studying them by advanced methods. The results are compared with predictions made by theoretical modelling. Work is on-going to optimize the fabrication of legs of the different materials and to design and assemble a full thermoelectric generator module with contacts.

What SINTEF can offer

For more information about SINTEF's competence on thermoelectric materials and devices:

For more information about other projects related to thermoelectric materials: