|

Mixed Technology

Non-standardized processes can be combined with standard Si/glass and polymer processes for enhanced functionality. The combined technologies often involve materials not used in the standard processes. Such mixing of the available microBUILDER technologies allows for improved functionality and higher performance of a variety of new devices. The processes offered through microBUILDER are technologies that enhance the functionality of separate silicon chips or separate polymer chips, or they are possible to combine with both silicon and polymer chips. Technologies that increase the functionality of silicon chips:

Technologies and elements that increase the functionality of polymer chips:

Technologies that can be used in combination with both silicon chips and polymer chips for increased functionality:

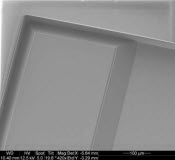

Deep Reactive Ion Etch SensoNor/SINTEF DRIE combined with the MultiMEMS manufacturing was used for the first microBUILDER demonstrator.

Standardized read-out electronics for piezoresistive sensors HSG-IMIT

Gold patterning on silicon and glass SINTEF The gold patterning process on silicon can be further developed to yield freestanding structures, e.g. cantilevers and membranes, with gold on top. Thiol and / or bio functional layers can later be added and the structures can then be used as mechanical biosensors. Complementary antibodies or DNA strands can bind to the attached receptor molecules and the molecular binding can be monitored by external, optical detection (color, fluorescence or beam bending) or by piezoresistive sensing as an integrated part of the sensor.

Piezoelectric films Some of the key differences between SINTEF and Tronics PZT processes are summarized below:

MoveMEMS PZT - Piezoelectric thin film SINTEF Applications can be classified according to those employing:

Several material systems of piezoelectric materials exist. The two most interesting alternatives for MEMS applications are aluminium nitride (AlN) and lead-zirkonium-titanate (PbZrTiO, shortened to PZT). Deposition of AlN is easy to industrialize, while the deposition techniques for PZT are far behind in maturity. However, PZT has an electromechanical coupling that is approximately 10 times higher than AIN and SINTEF has therefore developed the MoveMEMS PZT Chemical Solution Deposition (CSD) process.

Piezoelectric thick film PZT Tronics

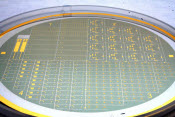

Hot embossing HSG-IMIT The hot embossing technology developed at HSG-IMIT is a technology which ideally meets the needs for prototyping, as it is less expensive for smaller volumes and offers more flexibility with respect to the outer dimensions of the polymer components. Furthermore, hot embossing is compatible with mass production processes. The hot embossing process is established for various substrate formats, e.g. rectangular standard microscope slide or CD-format disk, and for a selection of materials, e.g. COC, COP or PS.

Biocompatible Sealing of Polymer Chips HSG-IMIT The offered standard sealing method is a Solvent Diffusion Bonding process. This process is chosen as standard because it offers very high bond strength with high fluidic tightness (i.e. no leakage). The sealed microfluidic devices have a very high optical quality. Moreover, the covering foil is applicable for temperatures up to 100 °C. No adhesive or intermediate layers are necessary and as so the Solvent Diffusion Bonding process is a simple procedure. The biocompatibility of the process is examined by the activity of a stored enzyme (alkaline phosphatese) before and after the sealing processes. Other sealing processes as thermal diffusion bonding or sealing with a self adhesive foil are available on request.

Reagent storage HSG-IMIT In general, reagents can be stored both in liquid and solid state. While liquid storage is a milder procedure for less stable reagents, solid storage is suitable for long term storage. There can be no general approach to reagent storage as each reagent has specific requirements. Enzymes, however, are interesting reagents for dry storage as they are included in nearly all biochemical assays. They are a key component in various detection systems based on immunology, e.g. ELISA, PCR, and NASBA techniques. The amount of enzyme for an assay is relatively small, which allows for storage directly within the system’s fluidic network. Technology for dry storage of enzymes is therefore available through the microBUILDER consortium.

Filter slide thinXXS Different separation membranes can be integrated in a standard filtering slide.

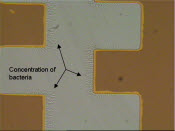

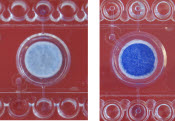

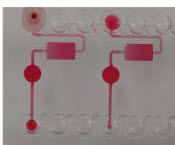

Cuvette polymer module thinXXS The cuvette slide is intended to provide a visualization platform for biological samples that is consistent with the slides existing in the thinXXS microfluidic construction kit (modular testing system). The slide consists of multiple, individual viewing chambers which are connected to separate fluidic ports via inlet and outlet channels. The sample is therefore pumped into the chamber, where it can be combined with additional chemistry and observed by either an automated imaging system or by a microscope. Also, standard glass cover slips and microscope slides are used to seal the chambers and would allow the user to perform tests with custom treated glass slides or microarrays. The self-assembly concept of the cuvette polymer module means it can be used in a wide variety of applications since the user has the flexibility to implement its own chemistry or materials. This includes many of the applications that are currently performed using microplates, cuvettes, and microscope slides. In particular, any processes which require interaction between a stationary or moving fluid and a biological material in an optically accessible cavity with a well-defined volume. Hydrophobic patterning HSG-IMIT Hydrophobic patterns (patches) in microfluidic structures are areas with water repellent behaviour due to hydrophobic coatings (contact angle > 90°). In such areas the capillary movement of a liquid can be manipulated. Micro channels with hydrophobic patches can act as passive valves or for metering since self-priming by capillary force is stopped and an additional pressure is needed to re-establish the flow over the patched area. Precise volume and position spotting of fluoropolymer-based solutions e.g. TEFLON AF is offered. The hydrophobic patches can be applied to surfaces after hydrophilization with e.g. PETOX or PEG.

Coatings for anti-binding or specific binding of bio macro-molecules on polymer and silicon chips and gold patterns on silicon or glass SINTEF

PDMS Channels in Polymer BME |

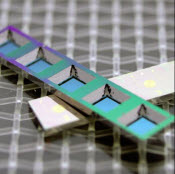

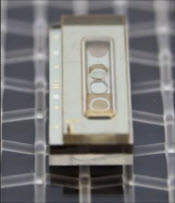

Interface slide for combining polymer and silicon technology

The interface slide with two integrated silicon based flow sensors

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||