She completed her PhD with HighEFF – Now she’s using the results in new projects

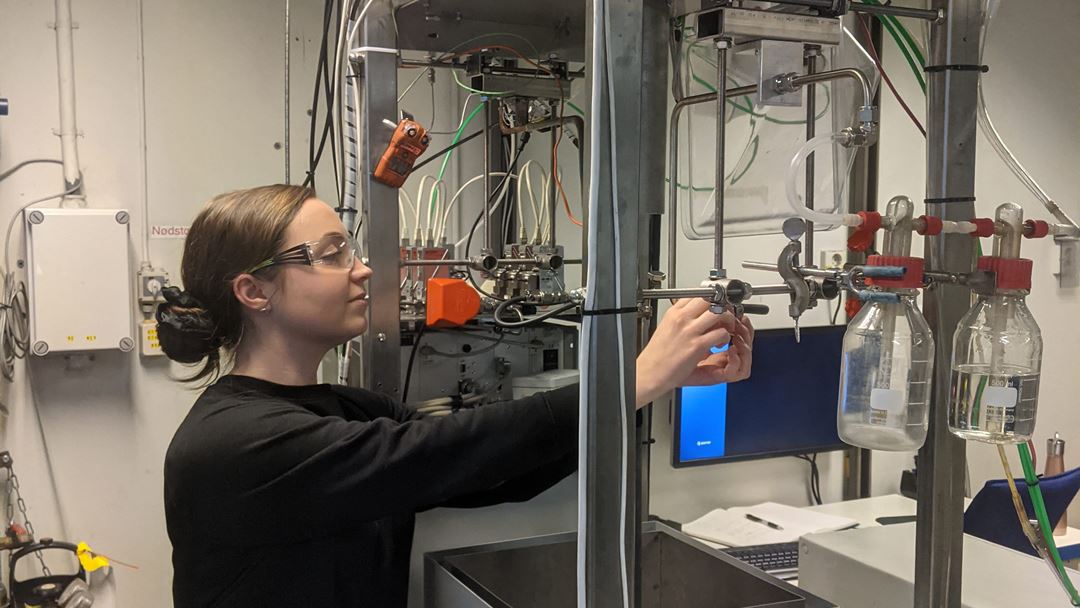

Trine Larssen was one of the first HighEFF research fellows to defend a PhD on December 17th, 2020, with her topic related to more environmental metal production.

She now works as a researcher at SINTEF, where industry partners are benefi tting from her HighEFF knowledge in other projects.

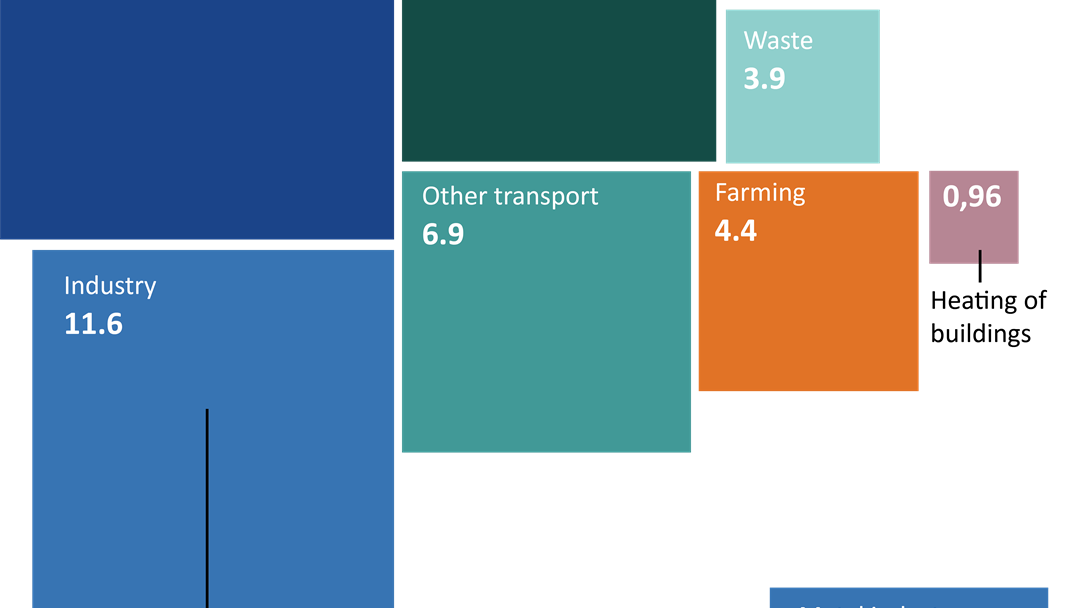

The large potential for emissions reductions in the metal industry

Norwegian industry is responsible for a quarter of the country’s greenhouse gas emissions. This is 43% less than just 30 years ago, but there is still room for larger cuts.

– The metal industry alone accounts for over 10% of Norwegian emissions. Obviously, if we are to reach our climate targets, we need to do research on how the metal industry can do its part, says Larssen.

Trine Larssen now works at SINTEF, where she researches metal production on behalf of the industry. In her doctorate, she specifi cally examined how ferromanganese production can become more energy effi cient.

– Ferromanganese is an unknown metal for many, but we produce a lot of it in Norway. It is used as an alloying element in steel, so it’s a very important metal despite it being relatively hidden from view for most people.

Using PhD results in projects that are relevant for the industry

Many of the companies producing ferromanganese in Norway are HighEFF partners. They were closely involved in Trine Larssen’s research to help make sure the PhD was as relevant as possible to the industry. Specific issues and questions from ferromanganese producers were central to Larssen’s work. The industry was involved in her research throughout, which has proved very valuable to both parties.

– The industry confi rmed that the skills and knowledge I have acquired are both useful and usable to them. The doctorate also placed me in an advantageous position to get the job I have today.

– The companies I worked with as part of HighEFF are taking part in many other SINTEF projects. During the two months I have worked here, I have had the opportunity to work for metal industry-related projects where I’m basically building on the results presented in my PhD.

A more energy-effi cient industry

– Making processes more energy effi cient is a crucial part of greening up any type of industry. Broadly speaking, improved energy effi ciency means that a factory produces just as much as before, but with less energy. In other words, they get more, for less, Larssen explains.

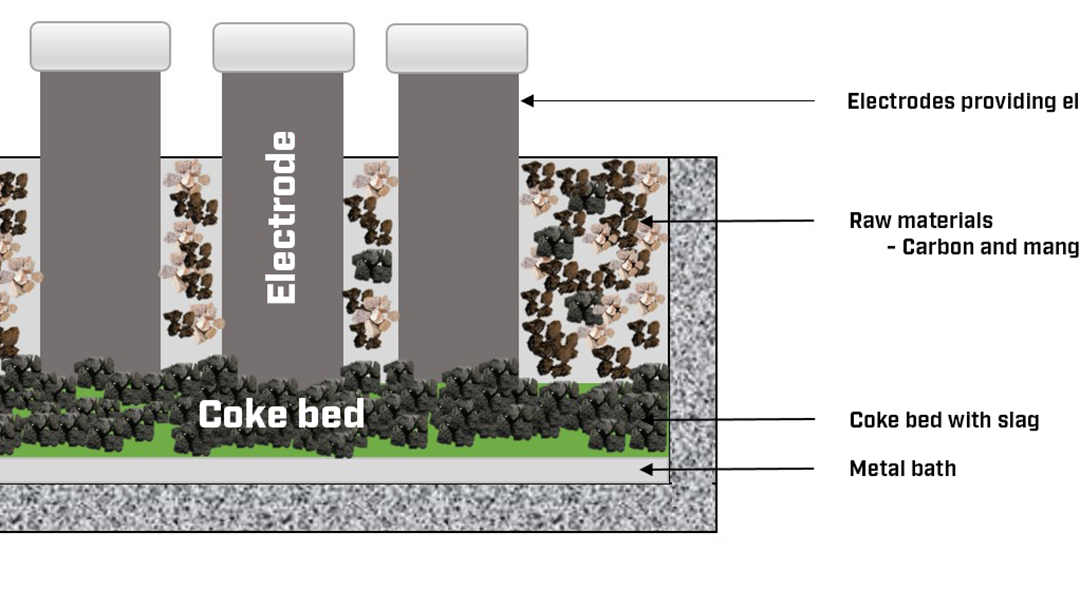

When Larssen was tasked with examining how ferromanganese production can become more energy efficient, she had to look at the amount of energy required to produce the metal, as well as the types of exhaust gases released during production.

– During production, carbon is used to remove oxygen from the ore. This means that we also generate lots of carbon monoxide (CO) and carbon dioxide (CO2) that get released from the furnace as exhaust gas. This gas can almost be seen as a side eff ect of the process. It’s unavoidable if we’re going to be producing the metal, Larssen explains.

She adds that of all the chemical reactions happening during ferromanganese production, a few are particularly interesting to look at more closely.

– Some reactions that happen between the ore and the gases in the furnace have a great eff ect on energy use and greenhouse gas emissions. In my doctoral thesis, I delve into these reactions for two diff erent types of manganese ore – comparing their eff ect on energy use and exhaust gas generation.

These results were used to calculate the size of CO2-equivalent emissions generated by the industry when they use these diff erent types of ore. Larssen also established how the size of the ore aff ects emissions. Finally, she found out what kind of eff ect the composition of the gases present in the furnace has on the chemical reactions happening inside.

How was it to do complete a PhD in collaboration with HighEFF?

– HighEFF is diff erent from other research centres I worked closely with in the past, because it collaborates with such a wide variety of industries. This means that I’ve simultaneously scrutinised a topic in great detail and widened my horizons.

Larssen says she also learned how to work more efficiently during the course of her doctorate work.

– Taking a deep dive into a single topic for three years is not something you get to do very often. It’s a very special thing, and you have the time to really leave no stone unturned. Yet this process has taught me to balance my time use against the goals of my work. When you do a PhD, you have a lot of time, and that means I can sometimes get side-tracked by details that are perhaps not that important in the grand scheme of things. Knowing how to get to the point you have reach to fi nd out what is important – but no further – that is a skill I will remember.