Potential uses of CO-rich off-gas from Mn ferroalloy production

Mapping a landscape of possibilities

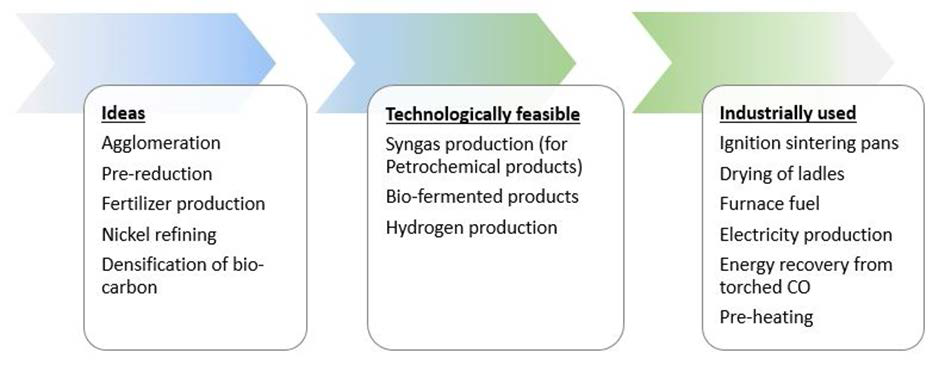

In FME HighEFF, a number of case studies will be carried out in the research area (RA) 6 for the Materials and Metals sector. In 2017, funding from work packages 6.1 and 6.4 are combined in one case study on the possible ways to utilise CO-rich off-gas from Mn ferroalloy production. A way to make use of the large and diverse consortium was to collect ideas on potential uses for CO gas. An e-mail was sent out in the FME consortium in an attempt to collect and identify unconventional and "crazy" ideas. In addition, the task would summarize the more conventional lines of thought for solutions which may serve as a basis for new business opportunities.

It is clear from the current report that it is possible to use CO gas for many things, including some exciting new opportunities. The report identifies, however, a number of risks, challenges and possible show stoppers. Gas composition (purity) will be an important issue for several applications. For many applications, it will be necessary to address the challenges connected to variations in gas pressure, availability and composition. Nonetheless, there are good reasons to pursue many of the ideas listed herein.

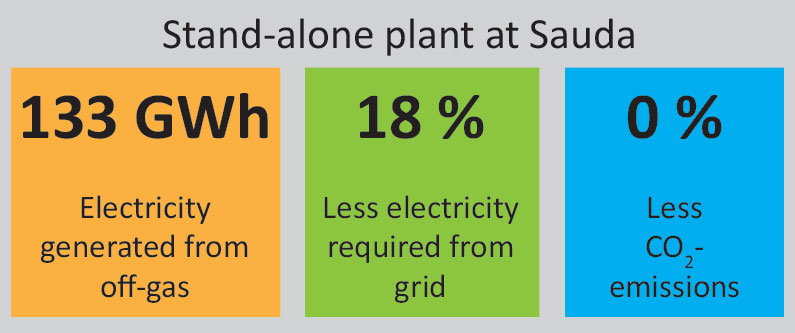

Off gas utilisation example: Stand-alone plant at Sauda

Currently, the CO-rich furnace off-gas is flared but the combustible gas can be burned for thermal power generation instead, reducing the electricity bought from the grid by 18%.

Power generation would not result in lower greenhouse gas emissions but in significantly improved gas utilisation and energy efficiency of the plant.

Thermal power plants for flue gas are commercially available and off gas with around 60% CO have reportedly mgiven efficiencies of around 37% for power generation.