Introduction

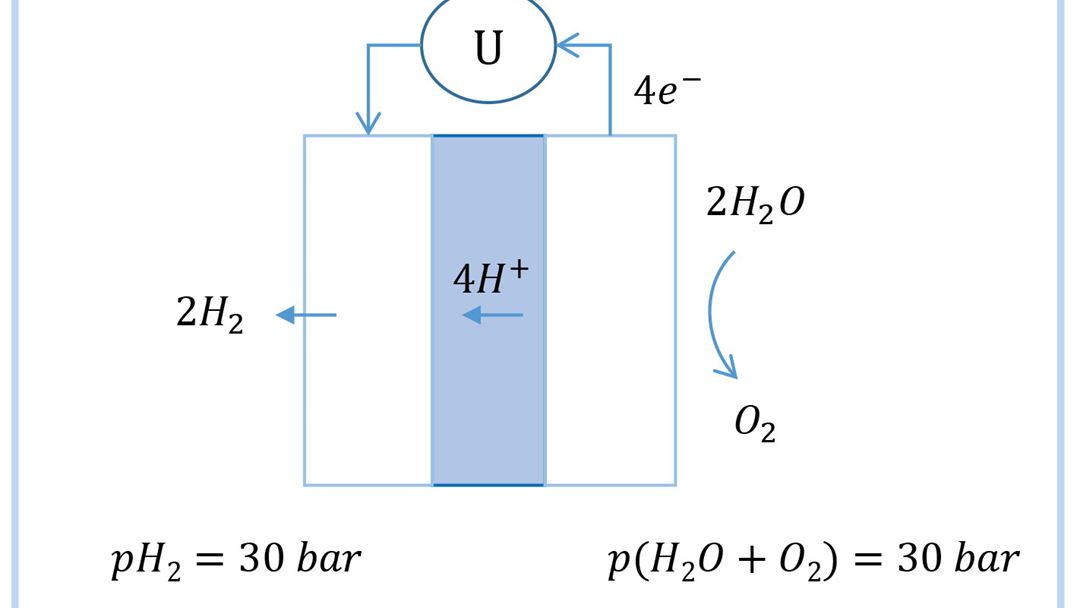

The GAMER project will develop a novel cost-effective tubular Proton Ceramic Electrolyser (PCE) stack that will produce pure dry pressurized hydrogen.

The electrolyser system will be thermally coupled to renewable or waste heat sources in industrial plants to achieve higher AC electric efficiency and efficient heat valorisation by the integrated processes.

The project will establish the science and technology for high volume production of the novel tubular proton conducting ceramic cells. The cells will be qualified for pressurized steam electrolysis operation at intermediate temperature (500-700°C). They will be bundled in innovative single engineering units (SEU) encased in tubular steel shells, a modular technology, amenable to various industrial scales.

GAMER will develop designs of system and balance of plant components supported by advanced modelling and simulation work, flowsheets of integrated processes, combined with robust engineering routes for demonstrating efficient thermal and electrical integration in a 10 kW electrolyser system delivering pure hydrogen at minimum 30 bar outlet pressure.

Download our new article published in Nature materials!

Mixed proton and electron conducting double perovskite anodes for stable and efficient tubular proton ceramic electrolysers.

https://www.nature.com/articles/s41563-019-0388-2