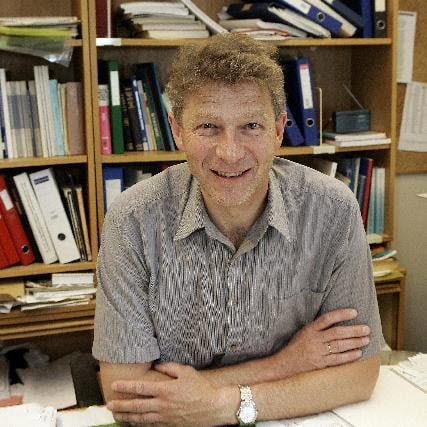

- Name

- Terje Kanstad

- Title

- WP Lead / Professor

- Organization

Work Packages

WP1 - Early age cracking and crack calculation in design

The ability to predict and limit cracks on short (building/hardening phase) and long term (serviceability phase) in concrete structures exposed to harsh environment is part of this work package, as well as the impact of cracks on durability, aesthetics and tightness in general.

The work package is divided into three parts:

WP 1.1 Crack risk assessment of concrete structures at early ages

WP 1.2 Calculation of crack spacing and crack widths

WP 1.3 Relevance of crack requirements

WP1-1 Crack risk assessments of concrete structures at early ages

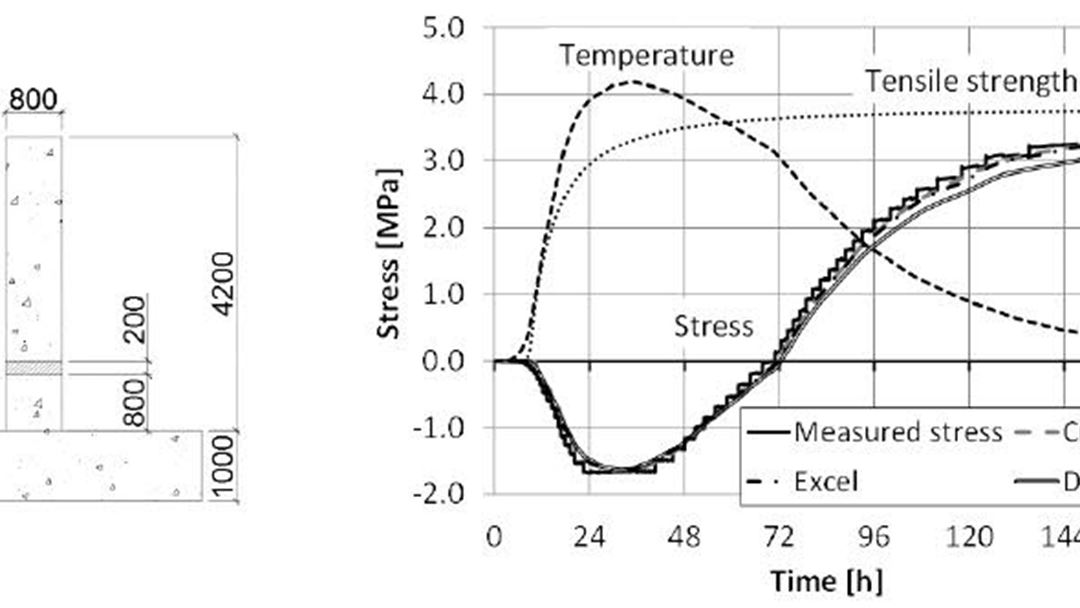

Within the first part of the project, stress based curing technology for crack risk assessment is applied. In this project experimental test equipment for measurement of free deformations (FD system) and restrained stresses (TSTM system) and a calculation tool (CracktestCOIN) have been used. The research has been focused on determination of material properties as thermal dilation, autogenous shrinkage, mechanical properties and creep for concretes with modern environmentally friendly cements suitable for harsh environments. The project has also contributed much to a new Annex D for Eurocode 2 entiled: Evaluation of early-age and long-term cracking due to restraint.

This is a large and challenging activity and several combinations has been tested representative for structures that are exposed to harsh climatic conditions.

Working group

Terje Kanstad, BTBU

Anja Klausen, NTNU

Øyvind Bjøntegaard, Statens vegvesen

Sverre Smeplass, Skanska

Knut Kjellsen, Norcem

Berit Gudding Petersen, Unicon

Bernt Kristiansen, AF

Andreas Sjaastad, Veidekke

Thomas Beck, Mapei

WP1-2 Calculation crack spacing and crack widths

The goal of this work package has been to investigate if there is any potential for improvement of the crack width formula, and on a more general note, the crack width prediction literature. The goal was set out based on experience from the industry partners that the predicted crack widths did not match the in-situ. It was also unclear where in the concrete section the crack widths were predicted from the formulas.

The work in this WP has found that: a) the crack width formula has improvement potential due to the inconsistency in current formulation, b) the crack width predicting methods in the literature and in the standards focus on, and is empirically adjusted to, predict the crack width on the concrete surface, c) the test specimens, that the current formulas are derived from, are generally sparsely reinforced, has small concrete covers and are often loaded unidirectional, all contradicting the situation for heavily reinforced large concrete structures in harsh environments.

To enhance the understanding the program has performed laboratory tests on specimens representing large concrete structures, with relatively dens reinforcement and large covers. Based on the laboratory tests and test results from the literature a surface crack width prediction model has been derived and is suggested for international standards. The proposed model predicts the surface crack width of reinforced concrete structures in a more consistent and precise manner than today's crack width prediction formulas proposed by the standards.

Working Group

Terje Kanstad, NTNU

Morten Engen, Multiconsult

Dan Evert Brekke, Multiconsult

Reignard Tan, Multiconsult

Anja Klausen, NTNU

Mikael Bastesgaard, Concrete Structures

Kjell Tore Fosså, Kvaerner

WP1-3 Relevance of crack requirements

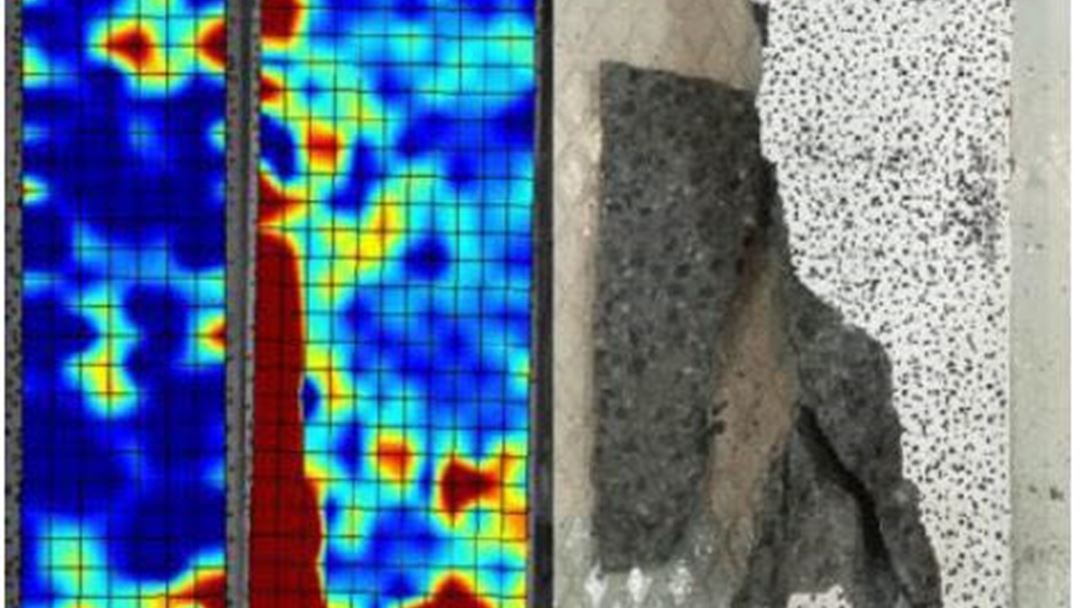

This program is related to the strong need for evaluation of todays requirements considering harsh exposure situation due to climatic conditions, construction of structures in arctic areas, and the utilization of new more environmentally friendly binders in the concrete. Traditionally, the durability for new concrete structures has been satisfied based on the permeability properties in the concrete and the depth of the cover zone. However, during the construction phase and often in spite of good planning, surface cracks are sometimes developed for one or several reasons. The question is: what impact do the cracks- their width, shape and depth - have on durability and service life of a structure? In this WP, investigations are performed on existing structures in order to identify any impact of surface cracks and crack width on durability.

The conclusion is that sufficient rebar cover, together with good concrete quality and also good consolidation during concrete placement have decisive impact on the durability. Small surface cracks seem to be of less importance for durability. There are so far found limited connections between rebar corrosion and cracks. Embedment parts can have an impact on durability and can be a reason for early reinforcement corrosion.

Working Group

Terje Kanstad, NTNU

Kjell Tore Fosså, Kvaerner

Anja Klausen, NTNU

Mette Geiker, NTNU

Tobias Danner, SINTEF

Mikael Bastesgaard, Concrete Structure

Morten Engen, Multiconsult

Karla Hornbostel, Statens vegvesen

WP2 - Production and documentation of frost durable concrete

The primary objective has been to investigate requirements to part materials, production and exposure to obtain concrete materials with adequate frost resistance both for onshore and offshore severe exposure. The project has mainly been dealing with sustainable binder materials. The objective has also included innovative solutions for production and use of durable concrete under varying kinds of frost exposure. In addition the following secondary objectives were targeting:

- Develop robust admixture – binder combinations for air entrainment and frost resistance under varying production conditions

- Obtain resistance against internal cracking due to wet freeze/thawObtain resistance against salt/frost surface attack test.

- Studies of the effect of frost induced internal cracking on surface scaling to understand and be able to interpret the results of these two tests better

- Evaluate the most common freeze/thaw tests and their evaluation criteria

- Study the effect of frost and air entrainment on freezing induced stress in reinforced concrete to be able to understand the importance of internal cracking for structural behaviour

- Study the effect of water penetration in cracks and effect of freeze/thaw

The work has focused on high volume fly ash concrete exposed to two types of exposure: frost-salt attack as in the European slab test, and rapid freezing and thawing and internal cracking according to the ASTM rapid freeze/thaw test. These are the main types of tests that producers of marine concrete structures for the arctic are going to be faced with. Hence a thorough review of requirements and recommendations as well as some special studies on effect of very low temperature, mutual, or reciprocal, effects of scaling and cracking, were investigated. Also, the production aspects on air entrainment, curing and pore structure were investigated.

Working Group

Stefan Jacobsen, NTNU

Andrei Shpak, NTNU

Kjell Tore Fosså, Kværner

Ernst Mørtsell, Nordbetong

Bård Pedersen, Statens vegvesen

Ola Skjølsvold, SINTEF

Thomas Beck, Mapei

WP3 - Concrete ice abrasion

The work package is aimed to increase the understanding of the mechanisms behind concrete-ice abrasion through laboratory experiments of high-performance concrete and repair mortar.

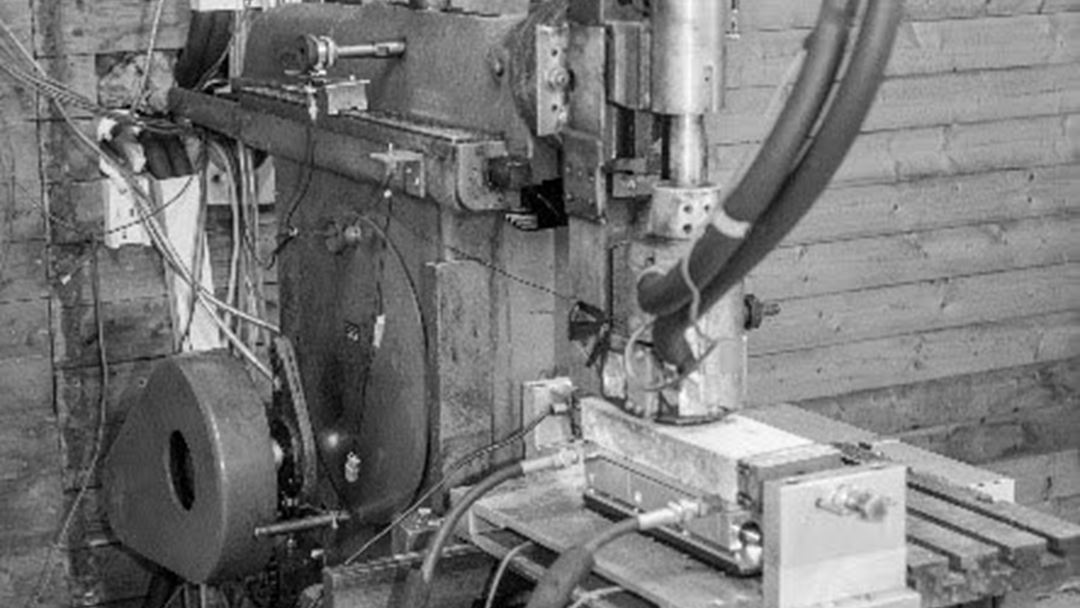

The research has been performed with the ice abrasion rig located at NTNU. A non-standard laboratory abrasion rig has been further developed for simulation concrete-ice abrasion. A new laser scanning method for measuring an abrasion depth has been developed. Moreover a new method for ice production was used, which allowed to get air-void free ice with defined density and crystal structure.

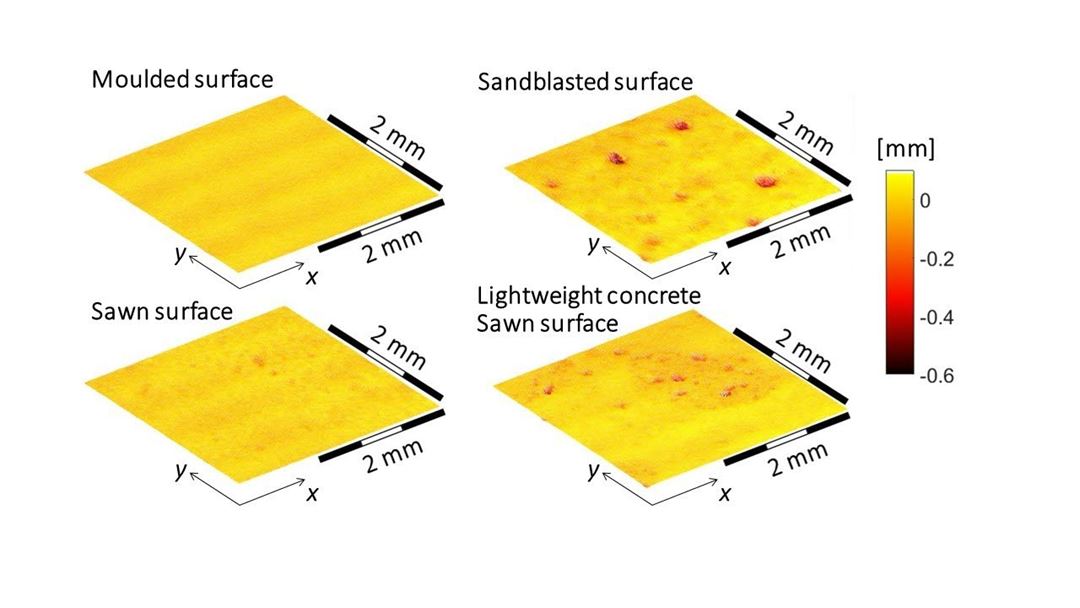

During the project, several types of concrete mixes have been tested: B75, B85, air-entrained concrete B70 5% air, lightweight concrete LB60, Repair Mortar. Concrete with and without frost exposure (ASTM C666) has been tested to ice abrasion. The new laser scanner allow to perform a topography study on different concrete surfaces (sawn, moulded and sand-blasted) during the concrete-ice abrasion tests.

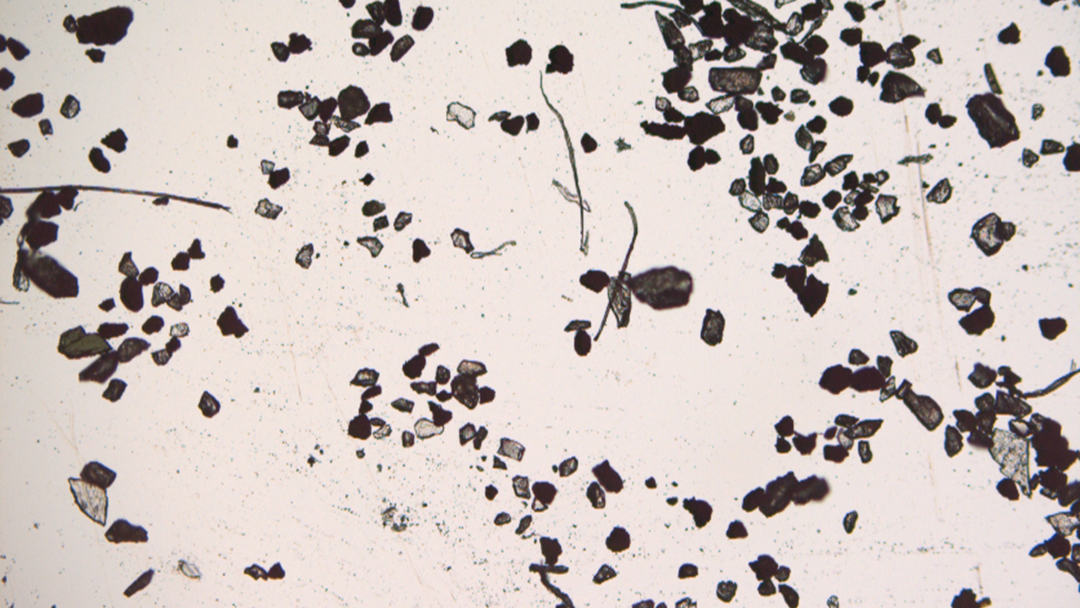

The focus of this the research was on new parameters for concrete-ice abrasion. We were able to capture different ice fracture modes, variation of coefficient of friction during the test, concrete surface parameters, concrete wear particles and ice wear fragments.

In this project, laboratory tests showed average abrasion depths of 0.01 – 0.35 mm for high-performance concrete after 3 kilometres of sliding ice, the prediction model based on laboratory measurements was obtained. The pilot lattice model of interaction between ice asperity and concrete surface was developed, with respect to laboratory experiment.

Working Group

Stefan Jacobsen, NTNU

Guzel Shamsutdinova, NTNU

Kjell Tore Fosså, Kvaerner

Egil Møen, Multiconsult

Trond Helgedagsrud, Mapei

WP4 – Ductile durable Light Weight Aggregate Concrete (LWAC)

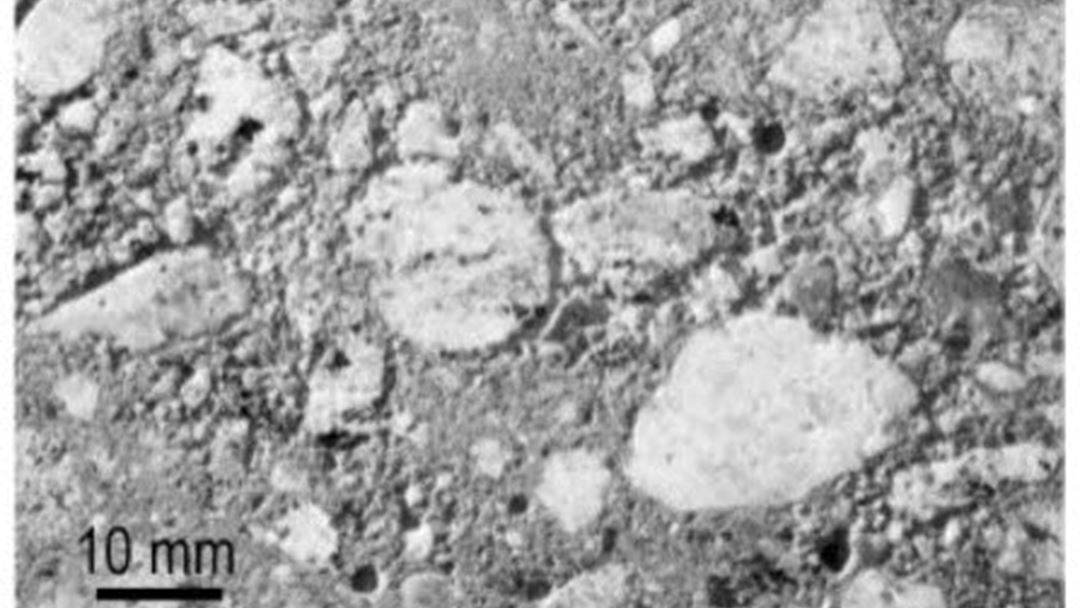

The objective has been to document and improve the ultimate compressive strain in lightweight aggregate concrete. The study includes also the influence of different types of confinement. The confinement effect comes from reinforcement bars or by adding fibres to the concrete. An experimental program was necessary to investigate the confinement effects on the compressive ductility. The lower weight is obtained by using light weight aggregate, Stalite (expanded slate) from North Carolina, replacing the coarse aggregate in the concrete.

The main goals in this work were:

• Design an LWAC mix with sufficient workability also when adding fibres

• Study the effect of different types of reinforcement configurations on compressive ductility

• Study the effect of strain gradients on the ductility

• Derive material models to be used in numerical analysis or design which include confinement effects

The results show that the ultimate strain in LWAC is higher than what is to be assumed in the standard. Concrete with pre-moistened LWA is more brittle and explosive in moment of failure than concrete with dry Stalite aggregates. LWA-concrete with fiber is more ductile and less brittle.

Working Group

Jan Øverli, NTNU

Jelena Zivkovic, NTNU

Hans Stemland, SINTEF

Kjell Tore Fosså, Kvaerner

Arianne Minoretti, Statens vegvesen

Silje Gystad Ytterdal, Multiconsult

Rolf Valum, Axion