Material life cycle-thinking

Our actions affect the environment in ways we may not understand when we decide what products to use and how to use them. What are they made of and how are they made? How do we use them and how do we dispose or recycle them? In the DACOMAT project we use LCA and LCCA to reduce our impacts. Here we explain what they are and why they are important tools.

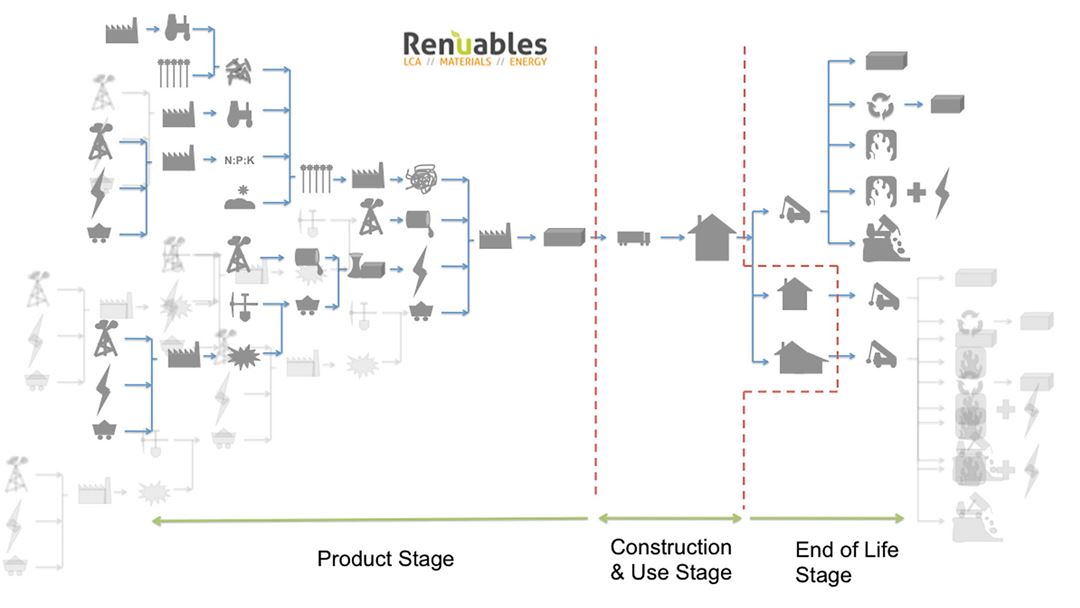

Life Cycle Assessment (LCA) is a technique to assess environmental impacts associated with some or all the stages of a product's life. This may include raw material extraction, materials processing, manufacture, distribution, use, repair and maintenance, and disposal or recycling. This technique can be used on many levels, from large studies of new materials or processes in particular scenarios to inform materials' choice or policy, or product specific calculations to display a carbon footprint on food on the supermarket shelf.

Regarding product footprints, certain standards have to be followed, so that the results can be used in a way that allows a fair comparison between other products that perform the same task. The most common of impact (or characterisation factor) studied is the product's Global Warming Potential (GWP) or Carbon Footprint, but other factors may be displayed concerning resource depletion, ozone creation, energy demand and acidification.

With Life Cycle Cost Analysis (LCCA) a similar technique is used but instead of quantifying the environmental impacts associated with the flow of materials and energy, the financial implications are considered.

Both LCA and LCCA are an important element in the DACOMAT project. Changing a composite in a structural element may result in an increased environmental impact, but if over the whole life cycle there is a reduced maintenance requirement, then overall the environmental impact may be reduced. The only way to be sure is to use LCA and LCCA.

The first aspect of this study has been to determine what the environmental impact of the different components in the composites is. Work is now proceeding to understand the environmental impacts of a bridge span made from composites, concrete, or steel. For this project the main characterisation factor of interest is primarily GWP. The other parameter of interest is the embodied energy, which is the primary energy that is used in manufacturing, transporting, maintaining and disposal.

Because LCA and LCCA are being used here to assess whole life cycles, they become useful tools for highlighting hotspots in areas such as processing and disposal that may cause a high environmental impact or cost. Highlighting such issues is vital for demonstrating tradeoffs between performance and in-use impacts and also for optimising the materials we produce. Throughout the DACOMAT project we will continue to report on our findings.

Written by: Dr. Andrew Norton, Prof. and Callum Hill.