About

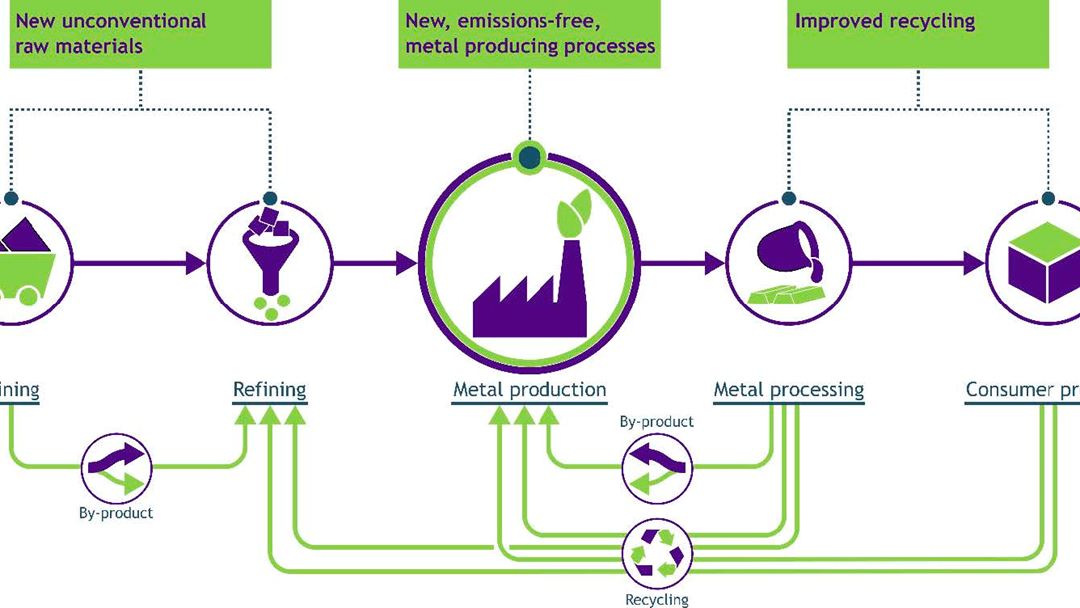

TEMP-lab is a national laboratory for research into sustainable metallurgy, funded by the Research Council of Norway through the INFRASTRUKTUR-programme. TEMP-lab will provide the required infrastructure for the research efforts needed to accelerate Norwegian Industry and R&D in the transition to more sustainable resource utilisation in metal production. The infrastructure will follow metals and raw materials along the whole value chain from the mine to end-of life recycling, with a circular, zero-waste vision

The project launched late 2022, and will run until 2027. The first pieces of equipment was installed in spring of 2023. A complete list of available infrastructure can be seen under “Facilities”.

The project partners are SINTEF and NTNU, but the instruments and infrastructure nodes of TEMP are available to external researchers and industries.

In the transition towards a more climate friendly economy, demand for metals is still going to grow, e.g. in wind turbines, solar parks, electrified transport, and consumer goods. However, many of the metals produced today come with large CO2-emissions, high energy requirements, and environmental problems related to mining, processing, industrial and end of life wastes. These problems are exacerbated by insufficient resource efficiency along the value chain, which means that part of the valuable fractions in the mined ore does not end up as a product.

This creates industrial waste, which, despite often being richer in metal content than the orebodies they were extracted from, are un- or underutilised as secondary raw material sources. In addition, significant amounts of end-of-life metal containing products are currently not recycled and, if recycled, mostly downgraded to less valuable products.

A transition to a more sustainable resource utilisation in metal production is needed. This includes higher primary and secondary resource efficiencies, better energy efficiencies, and zero net CO2-emissions while facilitating complete metal products circularity. TEMP will supplement existing infrastructure to cover, for the first time, the complete research value chain in the transition to more sustainable methods in metals production and recycling.

Objectives

The objectives of TEMP-lab are as follows:

- Raw Materials Utilisation: Provide laboratory equipment that facilitate development of processes for recovery and utilisation of unexplored valuable raw materials from existing processes as well as recovery from unconventional raw materials. This includes materials such as mine and industrial tailings, industrial wastes, and by-products, including recovered materials described under the other objectives.

- End of Life Products: Provide laboratory equipment to study recycling of end of life products (e.g. from urban mining) with recoverable metals. This includes difficult to recycle components, with a special focus on avoiding downgrading of the metals and alloys to less valuable products, and closing the circle of the metal value chains to reach zero waste of valuable products.

- Fossil Free Production: Provide laboratory equipment directed towards the study of metal production without fossil based reducing agents.

- National and International Impact: Strengthen the attractiveness of the existing Norwegian infrastructure and the partners in national and international research initiatives for sustainable and circular metallurgy.

- Industrial Accelerator: Facilitate industrial relevant research as the basis and first step towards industrial pilots outside the infrastructure.

TEMP pursues these objectives across three main, interconnected areas important in metal production:

- Pyrometallurgical processing, including new and more environmentally friendly and zero emissions solutions with less use of fossil-based reduction materials, increased raw materials utilisation and use of secondary raw materials.

- Hydrometallurgical processing, covering extraction and separation from primary ores as well as secondary sources including recycling of complex end of life products and metals.

- Electrometallurgical processing, both aqueous and molten salt and molten oxide electrolysis, including developments within cell and electrode materials.