About Green Hydrogen

Hydrogen is a clean and versatile energy carrier, which, together with renewable electricity, is expected to realize decarbonisation of the global energy consumption.

Hydrogen can be used as:

- zero emission fuel for transportation (especially heavy-duty, maritime and rail)

- heating and power generation in places where it is difficult to use electricity

- CO2-neutral feedstock for chemical processes, e.g. for steel and ammonia production

Green hydrogen is hydrogen produced out of water and electricity from renewable energy sources such as wind, solar or hydro. In an electrolyser, water is separated in hydrogen and oxygen without any CO2 emissions. This way, hydrogen can also act as a vector for renewable energy storage, ensuring back up for seasonal variations and allowing for distributed production located close to the demand centres. A priority of EU's energy transition is to develop a green hydrogen market and value chain, using mainly wind and solar energy for the production. Green hydrogen is the most compatible option with the EU’s climate neutrality and zero pollution goal in the long term and the most coherent with an integrated energy system. The ambition is to have at least 6 GW electrolyser capacity in 2024.

In addition to green hydrogen, it is possible to produce hydrogen from fossil fuels like natural gas and coal. However, production of so-called grey hydrogen emits large amounts of CO2 (in the range of 10 tons CO2/ton H2). Blue hydrogen is also produced from fossil fuels, but most of the CO2 emissions are captured and either permanently stored or utilized in other processes or products. With carbon capture and storage (CCS) at a 90% CO2 capture rate, still about 1 ton CO2 is released per ton of H2 produced. Comparing blue hydrogen from natural gas with the planned 6 GW of electrolyser capacity in the EU by 2024, green hydrogen will reduce CO2 emissions with up to 6 million tons per year[1], corresponding to the emissions of more than 2 million cars.

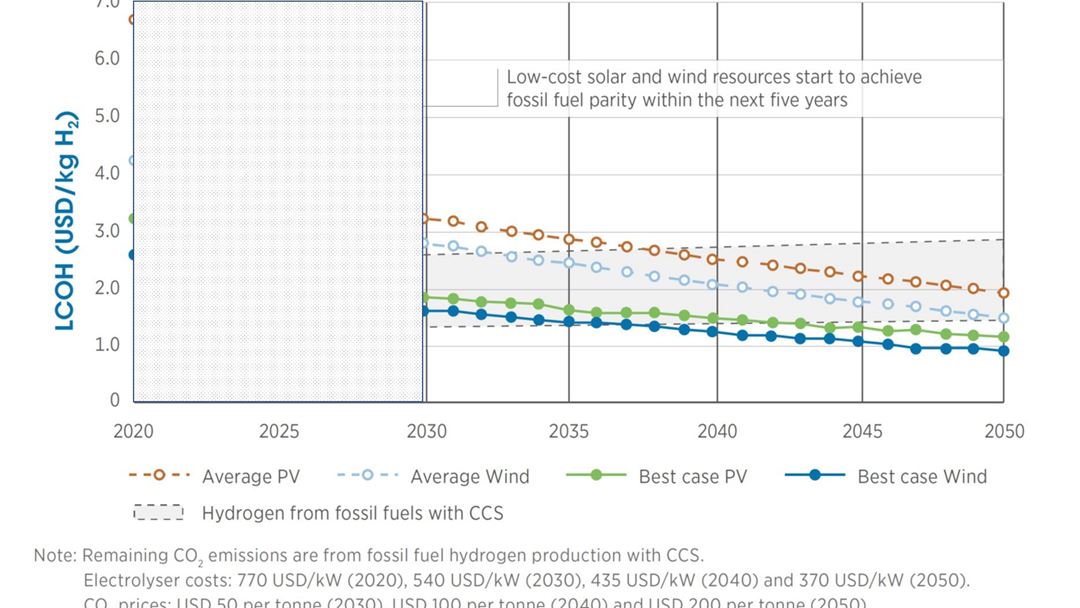

Currently, most hydrogen is produced by steam reforming of natural gas with large CO2 emissions. When it comes to CCS, only 3 EU countries have a high readiness for CO2 storage and thus would have an opportunity to produce hydrogen from fossil fuels in combination with CO2 storage. According to a recent study, most CCS routes are not expected to become competitive in the 2030 time horizon[2]. Both IRENA[3] and IEA[4] indicate that around that point of time green hydrogen costs will be equal or lower than hydrogen from fossil fuel with CCS, see figure to the left[5]. Also relevant here is the lower transport costs of green hydrogen, as it can be produced more locally, closer to the end users.

Another advantage of green hydrogen is the opportunity to be independent of energy import. According to a study by Wood Mackenzie[6], there is a big increase in the number of green hydrogen projects aiming at 100 megawatts or higher electrolyser capacity. Mega-plants are planned for Australia, France, Germany, the Netherlands, Paraguay, Portugal, the U.K. and the U.S. In Europe alone, cumulative investments in renewable hydrogen could sum up to EUR 180-470 billion by 2050[7].

The choice for renewable hydrogen builds on European industrial strength in electrolyser production, will create new jobs and economic growth within the EU and support a cost-effective integrated energy system. On the way to 2050, renewable hydrogen should progressively be deployed at large scale alongside the roll-out of new renewable power generation, as technology matures and the costs of its production technologies decrease.

[7] IRENA estimates that to achieve the Paris agreement around 8% of global energy consumption will be provided by hydrogen (IRENA, Global Renewables Outlook, 2020).