You are here:

CIV Arctic

/

Work packages

/

WP 4 - Systematic parameter variation

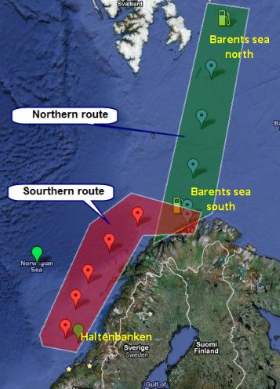

In parallel to the optimization of the aft hull a numerical parametric study of the CIV Arctic vessel was calculated in VERES. The study looked at the length parameter's influence on operability in Barents Sea regions. The parametric study consisted of a length-span of up to 60m longer and 20m shorter than the first version which has a Lpp of 109.3m. The study included operability comparisons for typical transit speed comfort criteria and operational criteria for selected typical operational tasks the CIV Arctic vessel was intended to do. The latter was a result of input from "WP 2 - Intervention philosophy and tasks" and several workshops with the industry, i.e. crane manufacturers and ROV operators. Also experienced personnel from STATOIL were present on several workshops to give guidance to select adequate tasks and thereby choosing relevant criteria for comparing the various designs. A decision from one workshop was that the vessel also should have satisfactory seakeeping characteristics in more southern regions than in the Barents Sea region and it was decided to extend the operational area with a "Southern route" of the CIV Arctic vessel to Haltenbaken, the southernmost point. Metocean input was received from met.no with help from STATOIL and used as a basis for the study.

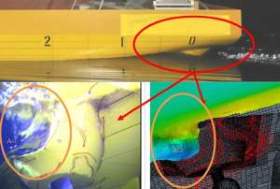

In parallel to the optimization of the aft hull a numerical parametric study of the CIV Arctic vessel was calculated in VERES. The study looked at the length parameter's influence on operability in Barents Sea regions. The parametric study consisted of a length-span of up to 60m longer and 20m shorter than the first version which has a Lpp of 109.3m. The study included operability comparisons for typical transit speed comfort criteria and operational criteria for selected typical operational tasks the CIV Arctic vessel was intended to do. The latter was a result of input from "WP 2 - Intervention philosophy and tasks" and several workshops with the industry, i.e. crane manufacturers and ROV operators. Also experienced personnel from STATOIL were present on several workshops to give guidance to select adequate tasks and thereby choosing relevant criteria for comparing the various designs. A decision from one workshop was that the vessel also should have satisfactory seakeeping characteristics in more southern regions than in the Barents Sea region and it was decided to extend the operational area with a "Southern route" of the CIV Arctic vessel to Haltenbaken, the southernmost point. Metocean input was received from met.no with help from STATOIL and used as a basis for the study. Then the hull model was shipped to Finland for ice performance testing in the Aker Arctic ice model tank. Special interest was made to the bulbous bow which was optimized for calm water performance which generally speaking is non-optimum for ice breaking. Though, by forwardly trimming of the vessel so that the bulbous bow was submerged below the free surface and the ice, the vessel showed satisfactory performance in ice. Since the vessel also was designed to break ice with the stern first, this was documented to be a good alternative to the bow first approach.

Then the hull model was shipped to Finland for ice performance testing in the Aker Arctic ice model tank. Special interest was made to the bulbous bow which was optimized for calm water performance which generally speaking is non-optimum for ice breaking. Though, by forwardly trimming of the vessel so that the bulbous bow was submerged below the free surface and the ice, the vessel showed satisfactory performance in ice. Since the vessel also was designed to break ice with the stern first, this was documented to be a good alternative to the bow first approach.