CEMCAP

WP11 Membrane-assisted CO2 liquefaction

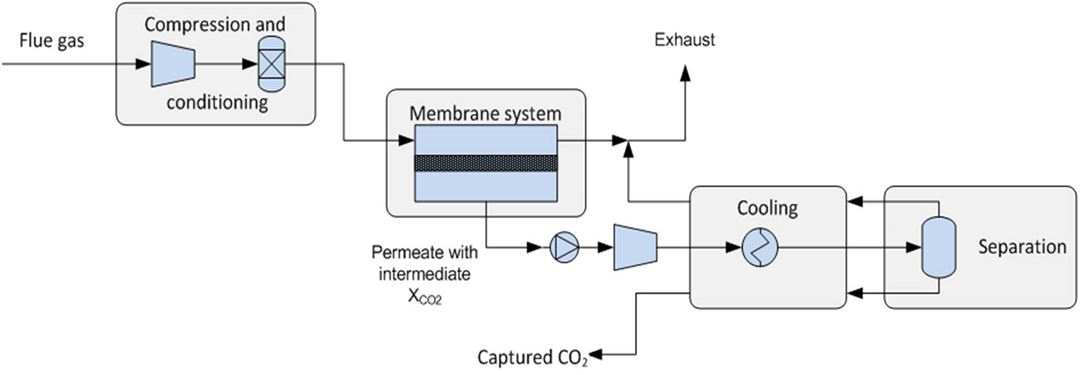

The objective of WP11 is to derive the optimal configuration for capturing CO2 in a two-stage separation process employing two different and complementary technologies.

In the first separation stage, CO2 is separated in bulk from the flue gas by permeation through a membrane module. Due to inherent limitations and practical trade-offs with respect to the ability of the membrane to selectively separate CO2 from the other gaseous components, the separation product will have limited purity. Therefore, additional purification is required.

The final purification and conditioning of CO2 is obtained in a low-temperature liquefaction unit in which the membrane permeate is conditioned and compressed, and subsequently cooled to a low temperature typically between -55°C and -50°C. At this point, the CO2 will be largely liquefied and can be separated from the more volatile components.

Optimisation of the membrane-assisted CO2 liquefaction process will require evaluation of several parameters and characteristics related to membrane material, process design and operation. This task involves theoretical simulations as well as experimental verification activities for both separation technologies in consideration.

Research partners in WP11 are SINTEF Energy Research (CO2 liquefaction) and TNO (membrane separation).