BioCarb+ – Enabling the biocarbon value chain for energy

About biocarbon

What is biocarbon?

Biocarbon is often called charcoal and is as such familiar to most people, as it is frequently used for cooking or barbequing. Even though charcoal is preferred before wood for these purposes, these combustion processes are far from optimal compared to what is possible in optimum combustion applications for charcoal as powder, briquettes or pellets.

Biocarbon results from a thermal conversion process in which the virgin biomass, e.g. wood, is heated to a certain temperature, losing a major part of its volatile content and, hence, increasing the relative carbon and fixed carbon content. The thermal treatment results in a product that has lost the fibrous structure of the virgin biomass and which can be used directly as a reductant in metallurgical industry or for cooking and barbecuing, or it can be easily and energy efficiently crushed to powder and if wished for further compressed into briquettes or pellets.

Biocarbon is NOT the same as torrefied material. Torrefaction is a lower temperature thermal process with the aim of upgrading a virgin biomass to a torrefied material, which also can be easily crushed to powder and turned into pellets. These pellets can then cost-efficiently be transported over long distances for the use mainly in large-scale cofiring plants, replacing coal, in powder burners.

Hence, biocarbon is a more refined and versatile product than torrefied material, and with the best fuel qualities that a biomass based solid fuel can have, and with many possible alternative uses.

Why biocarbon?

Biocarbon has many qualities and areas of use, as a fuel or for other purposes. Biocarbon is the optimum solid biomass fuel. It

- gives the most stable combustion conditions with the least emission variations and can easily and energy efficiently be crushed to small and close to spherical particles

- gives the highest heating value

- gives the highest energy density (mass, and volume when compressed) and bulk density (when compressed)

- gives the highest fixed carbon content

- has a high reactivity

- takes up very little water

- do not degrade bacteriologically during storage

- gives reduced logistics costs when compressed (transport and storage)

- gives reduced bioenergy plant investment needs

Compared to fossil coal biocarbon has:

- lower N, S and metal, e.g. Hg, contents

- lower ash content

and last but not least, it is renewables based.

The biocarbon fuel can be used as e.g. peak load fuel in existing bioenergy plants, as a substitute fuel for oil boilers, as quality fuel for high efficiency and low emission small-scale heating appliances, and in general for abating operational problems in bioenergy plants.

In the metallurgical industry biocarbon is a preferred reductant from a properties point of view in the production of e.g. silicon (Si), silicon carbide (SiC) and manganese (Mn). E.g. Si is used in the solar cell industry for production of solar cell panels. For solar cells one unit biomass energy in, gives around one thousand units of electricity out during the lifetime of a solar cell. This is indirect bioelectricity.

Finally, biocarbon can be used for different other purposes, e.g. as active carbon for cleaning/purification purposes or as soil productivity enhancer.

For all uses of biocarbon there will be optimum biocarbon production conditions that produce the best or the preferred biocarbon quality for the specific use. This optimum can also depend on the properties of the virgin biomass.

Where can biocarbon be used (as an energy source)?

Multi energy applications offering multi-TWh fossil fuel substitution but also new bioenergy potential:

- Peak load fuel in existing bioenergy plants (instead of oil)

- Substitute fuel for oil boilers

- Quality fuel for high efficiency and low emission small-scale heating appliances

- Fuel optimization by blending ("BIO CO-firing") and the use of low-grade and low-cost feedstocks e.g. tree tops and branches (GROT in Norwegian), straw, etc while maintaining energy efficiency

- High quality green coal for BtE plants, including co-firing

- Biocarbon as a reductant for Si, SiC and Mn production

A potential revolution in the Norwegian bioenergy future!

- National bioenergy strategy defined in 2008: 14 new bio TWhs by 2020 (i.e. a doubling)

- Main expected contributor: high quality (and expensive) woody biomass

- Other biomass resources include low-grade feedstocks such as branches and treetops

- (GROT), straw and other agricultural residues and can also include sewage sludge

- Disadvantages: physical properties (handling), chemical properties (poor fuel)

- Advantages: largely unexploited, cheap

- Upgrading such challenging fuels to biocarbon will dramatically change this picture

How is biocarbon produced?

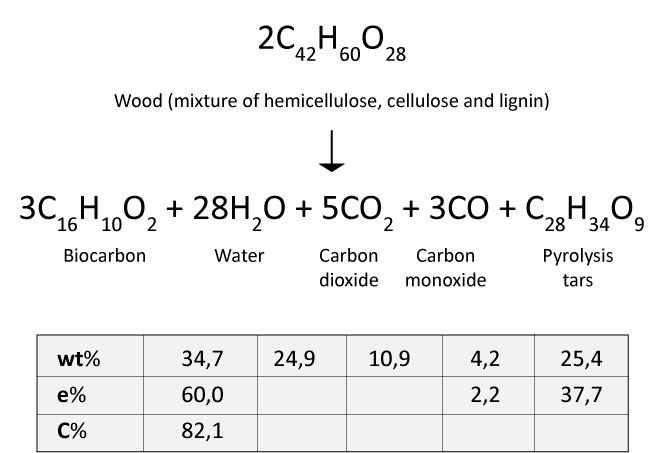

Thermochemical decomposition of biomass by heating in the absence of oxygen

- Products: solid (biocarbon), liquid (bio-oil) and syngas (CO2, CO, CH4, H2)

- Products’ yields and properties are dependent on both biomass chemical & physical properties and process conditions (peak temperature, heating rate, residence time, also P)

- Important biocarbon properties: volatile content, fixed C content, surface area, porosity

- Biocarbon is not a well-defined chemical compound

Some general data (SINTEF-NTNU-Hawaii cooperation, Energy & Fuels 2011, 25, 3251–3265)

- Biocarbon yield 25-55 wt%

- Fixed C content of biocarbon 60-90 wt%

- Peak temperature 400-800°C

- Low to moderate heating rates

- Long residence times (hours)

- High pressures can be used to favour high char yield, with reduced residence time

- Mechanisms are not well understood, especially secondary reactions (tar vapour cracking and recondensation)

Biocarbon and the combustion process

- Unique properties as a fuel in traditional combustion applications compared to other biomass solid fuels

- Stable combustion process (homogeneity)

- Low harmful emissions (NOx, SOx)

- Can be used as powder, pellets, briquettes (flexibility)

Carbonisation versus torrefaction

- Two very different processes

- Torrefaction is a low-temperature pre-treatment aimed at improving the grinding and densification properties of biomass while carbonisation produces a radically new and superior biomass fuel with coal-like properties

- These two solid products have rather different application fields

- Torrefied fuel is ideal for large-scale applications e.g. co-firing with low-grade coals

- Biocarbon is a perfect fuel for small-scale (up to 10 MWth) combustion applications, where the combustion process and emissions control possibilities are less than in large-scale combustion applications

- Biocarbon is also very well suited as a reductant for Si, SiC and Mn production