ad-blackoil: Black-oil solvers¶

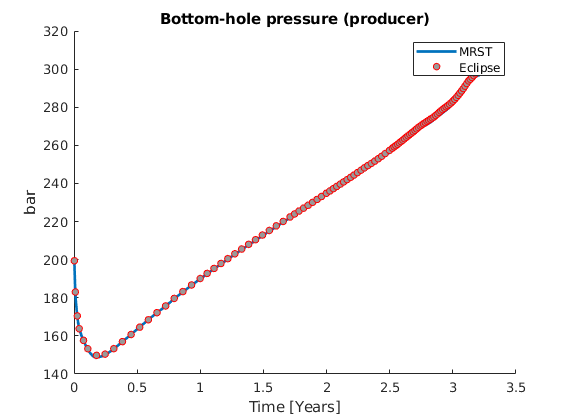

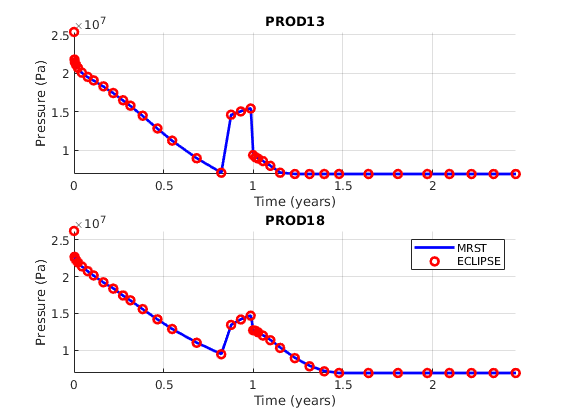

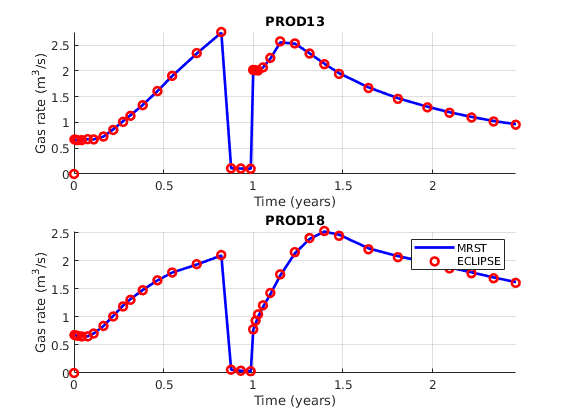

Models and examples that extend the MRST AD-OO framework found in the ad-core module to black-oil problems. More specifically, the module adds additional models that implement the black-oil equations for multiphase, miscible, compressible flow. Included in the module are also a wide variety of examples validating the solvers against a commercial simulator on standard test cases.

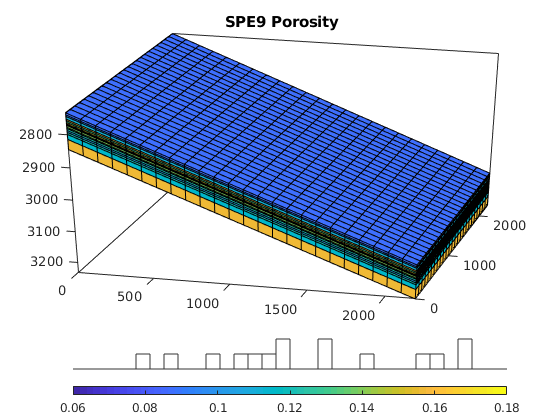

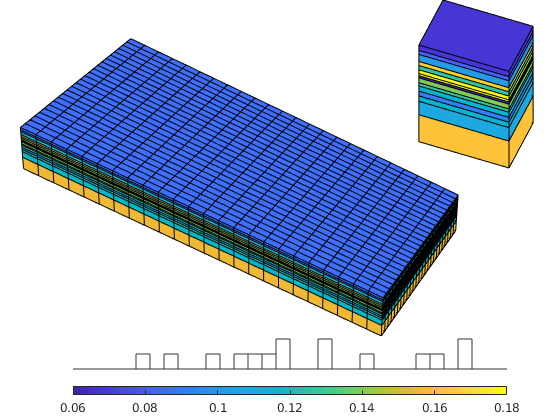

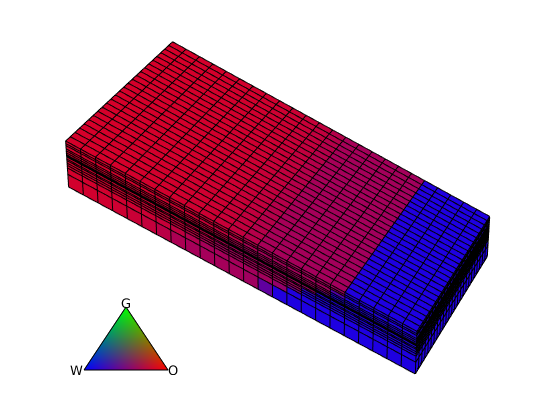

The module includes single-phase, two-phase and three-phase solvers. The three-phase solvers has optional support for problems where gas can dissolve into oil (Rs) and/or oil can vaporize into the gas phase (Rv). The solvers support source terms, boundary conditions and complex wells with changing controls, production limits and multiple segments. Standard benchmark cases (SPE1, SPE9) are included together with comparison results from a commercial simulator.

Models¶

Base classes¶

-

Contents¶ MODELS

- Files

- AquiferBlackOilModel - GenericBlackOilModel - ThreePhaseBlackOilModel - Three phase with optional dissolved gas and vaporized oil TwoPhaseOilWaterModel - Two phase oil/water system without dissolution WaterModel - Single phase water model. WaterThermalModel - Single phase water model with thermal effects. Should be considered

-

class

ThreePhaseBlackOilModel(G, rock, fluid, varargin)¶ Bases:

ReservoirModelThree phase with optional dissolved gas and vaporized oil

-

getPrimaryVariables(model, state)¶ Get primary variables from state, before a possible initialization as AD.

-

getScalingFactorsCPR(model, problem, names, solver)¶ Get approximate, impes-like pressure scaling factors

-

validateModel(model, varargin)¶ Validate model.

-

validateState(model, state)¶ Check parent class

-

disgas= None¶ Flag deciding if oil can be vaporized into the gas phase

-

drsMaxRel= None¶ Maximum absolute Rs/Rv increment

-

vapoil= None¶ Maximum relative Rs/Rv increment

-

-

class

TwoPhaseOilWaterModel(G, rock, fluid, varargin)¶ Bases:

ThreePhaseBlackOilModelTwo phase oil/water system without dissolution

-

class

WaterModel(G, rock, fluid, varargin)¶ Bases:

ReservoirModelSingle phase water model.

-

class

WaterThermalModel(G, rock, fluid, varargin)¶ Bases:

WaterModelSingle phase water model with thermal effects. Should be considered experimental and intentionally undocumented, as this feature is subject to change in the future.

-

insertWellEquations(model, eqs, names, types, wellSol0, wellSol, wellVars, wellMap, p, mob, rho, hW, components, dt, opt)¶ Utility function for setting up the well equations and adding source terms for black-oil like models. Note that this currently assumes that the first nPh equations are the conservation equations, according to the canonical MRST W-O-G ordering,

-

Utilities¶

-

Contents¶ UTILS

- Files

- assignWellValuesFromControl - Assign wellSol values when values are set as controls calculateHydrocarbonsFromStatusBO - Compute solution variables for the gas/oil/rs/rv-variable in black-oil computeAquiferFluxes - Undocumented Utility Function computeFlashBlackOil - Compute flash for a black-oil model with disgas/vapoil computeInitAquifer - Undocumented Utility Function equationsBlackOil - Generate linearized problem for the black-oil equations equationsOilWater - Generate linearized problem for the two-phase oil-water model equationsWater - Generate linearized problem for the single-phase water model equationsWaterThermal - Get linearized problem for single phase water system with black oil-style getbG_BO - Utility function for evaluating the reciprocal gas formation volume getbO_BO - Utility function for evaluating the reciprocal oil formation volume getCapillaryPressureBO - Compute oil-water and oil-gas capillary pressures getCellStatusVO - Get status flags for each cell in a black-oil model getDeckEGG - Get the parsed deck for the EGG model getFluxAndPropsGas_BO - Get flux and properties for the gas phase for a black-oil problem getFluxAndPropsOil_BO - Get flux and properties for the oil phase for a black-oil problem getFluxAndPropsWater_BO - Get flux and properties for the water phase for a black-oil problem getPolymerShearMultiplier - Compute the flux multiplier due to polymer shear thinning/thickening getWellPolymer - Undocumented Utility Function updateStateBlackOilGeneric - Generic update function for blackoil-like models

-

assignWellValuesFromControl(model, wellSol, W, wi, oi, gi)¶ Assign wellSol values when values are set as controls

Synopsis:

wellSol = assignWellValuesFromControl(model, wellSol, W, wi, oi, gi)

Description:

Well rates and pressures can be both controls and solution variables, depending on the problem. For a subset of possible well controls, this function explicitly assigns the values to the wellSol.

Parameters: - model – ReservoirModel-derived subclass.

- wellSol – wellSol to be updated.

- W – Well struct used to create wellSol.

- oi, gi (wi,) – Indices for water, oil and gas respectively in the .compi field of the well.

Returns: wellSol – Updated wellSol where fields corresponding to assigned controls have been modified.

See also

WellModel

-

calculateHydrocarbonsFromStatusBO(fluid, status, sO, x, rs, rv, pressure, disgas, vapoil)¶ Compute solution variables for the gas/oil/rs/rv-variable in black-oil

Synopsis:

[sG, rs, rv, rsSat, rvSat] = ...

calculateHydrocarbonsFromStatusBO(model, status, sO, x, rs, rv, pressure)

Description:

The ThreePhaseBlackOil model has a single unknown that represents either gas, oil, oil in gas (rs) and gas in oil (rv) on a cell-by-cell basis. The purpose of this function is to easily compute the different quantities from the “x”-variable and other properties, with correct derivatives if any of them are AD-variables.

Parameters: - model – ThreePhaseBlackOilModel-derived class. Determines if vapoil/disgas is being used and contains the fluid model.

- status – Status flag as defined by “getCellStatusVO”

- sO – The tentative oil saturation.

- x – Variable that is to be decomposed into sG, sO, rs, rv, …

- rv (rs,) – Dissolved gas, vaporized oil

- pressure – Reservoir oil pressure

- disgas – true if dissolved gas should be taken into account

- vapoil – true if vaporized oil should be taken into account

Keyword Arguments: ‘field’

RETURNS:

See also

equationsBlackOil, getCellStatusVO

-

computeAquiferFluxes(model, state, dt)¶ Undocumented Utility Function

-

computeFlashBlackOil(state, state0, model, status)¶ Compute flash for a black-oil model with disgas/vapoil

Synopsis:

state = computeFlashBlackOil(state, state0, model, status)

Description:

Compute flash to ensure that dissolved properties are within physically reasonable values, and simultanously avoid that properties go far beyond the saturated zone when they were initially unsaturated and vice versa.

Parameters: - state – State where saturations, rs, rv have been updated due to a Newton-step.

- state0 – State from before the linearized update.

- model – The ThreePhaseBlackOil derived model used to compute the update.

- status – Status flags from getCellStatusVO, applied to state0.

Returns: state – Updated state where saturations and values are chopped near phase transitions.

Note

Be mindful of the definition of state0. It is not necessarily the state at the previous timestep, but rather the state at the previous nonlinear iteration!

-

computeInitAquifer(model, initState, initaqvolumes)¶ Undocumented Utility Function

-

equationsBlackOil(state0, state, model, dt, drivingForces, varargin)¶ Generate linearized problem for the black-oil equations

Synopsis:

[problem, state] = equationsBlackOil(state0, state, model, dt, drivingForces)

Description:

This is the core function of the black-oil solver. This function assembles the residual equations for the conservation of water, oil and gas, as well as required well equations. By default, Jacobians are also provided by the use of automatic differentiation.

Oil can be vaporized into the gas phase if the model has the vapoil property enabled. Analogously, if the disgas property is enabled, gas is allowed to dissolve into the oil phase. Note that the fluid functions change depending on vapoil/disgas being active and may have to be updated when the property is changed in order to run a successful simulation.

Parameters: - state0 – Reservoir state at the previous timestep. Assumed to have physically reasonable values.

- state – State at the current nonlinear iteration. The values do not need to be physically reasonable.

- model – ThreePhaseBlackOilModel-derived class. Typically, equationsBlackOil will be called from the class getEquations member function.

- dt – Scalar timestep in seconds.

- drivingForces – Struct with fields: * W for wells. Can be empty for no wells. * bc for boundary conditions. Can be empty for no bc. * src for source terms. Can be empty for no sources.

Keyword Arguments: - ‘Verbose’ – Extra output if requested.

- ‘reverseMode’ – Boolean indicating if we are in reverse mode, i.e. solving the adjoint equations. Defaults to false.

- ‘resOnly’ – Only assemble residual equations, do not assemble the Jacobians. Can save some assembly time if only the values are required.

- ‘iterations’ – Nonlinear iteration number. Special logic happens in the wells if it is the first iteration.

Returns: - problem – LinearizedProblemAD class instance, containing the water, oil and gas conservation equations, as well as well equations specified by the FacilityModel class.

- state – Updated state. Primarily returned to handle changing well controls from the well model.

See also

equationsOilWater, ThreePhaseBlackOilModel

-

equationsOilWater(state0, state, model, dt, drivingForces, varargin)¶ Generate linearized problem for the two-phase oil-water model

Synopsis:

[problem, state] = equationsOilWater(state0, state, model, dt, drivingForces)

Description:

This is the core function of the two-phase oil-water solver. This function assembles the residual equations for the conservation of water and oil as well as required well equations. By default, Jacobians are also provided by the use of automatic differentiation.

Parameters: - state0 – Reservoir state at the previous timestep. Assumed to have physically reasonable values.

- state – State at the current nonlinear iteration. The values do not need to be physically reasonable.

- model – TwoPhaseOilWaterModel-derived class. Typically, equationsOilWater will be called from the class getEquations member function.

- dt – Scalar timestep in seconds.

- drivingForces – Struct with fields: * W for wells. Can be empty for no wells. * bc for boundary conditions. Can be empty for no bc. * src for source terms. Can be empty for no sources.

Keyword Arguments: - ‘Verbose’ – Extra output if requested.

- ‘reverseMode’ – Boolean indicating if we are in reverse mode, i.e. solving the adjoint equations. Defaults to false.

- ‘resOnly’ – Only assemble residual equations, do not assemble the Jacobians. Can save some assembly time if only the values are required.

- ‘iterations’ – Nonlinear iteration number. Special logic happens in the wells if it is the first iteration.

Returns: - problem – LinearizedProblemAD class instance, containing the water and oil conservation equations, as well as well equations specified by the WellModel class.

- state – Updated state. Primarily returned to handle changing well controls from the well model.

See also

equationsBlackOil, TwoPhaseOilWaterModel

-

equationsWater(state0, state, model, dt, drivingForces, varargin)¶ Generate linearized problem for the single-phase water model

Synopsis:

[problem, state] = equationsWater(state0, state, model, dt, drivingForces)

Description:

This is the core function of the single-phase water solver with black-oil style properties. This function assembles the residual equations for the conservation of water and oil as well as required well equations. By default, Jacobians are also provided by the use of automatic differentiation.

Parameters: - state0 – Reservoir state at the previous timestep. Assumed to have physically reasonable values.

- state – State at the current nonlinear iteration. The values do not need to be physically reasonable.

- model – WaterModel-derived class. Typically, equationsWater will be called from the class getEquations member function.

- dt – Scalar timestep in seconds.

- drivingForces – Struct with fields: * W for wells. Can be empty for no wells. * bc for boundary conditions. Can be empty for no bc. * src for source terms. Can be empty for no sources.

Keyword Arguments: - ‘Verbose’ – Extra output if requested.

- ‘reverseMode’ – Boolean indicating if we are in reverse mode, i.e. solving the adjoint equations. Defaults to false.

- ‘resOnly’ – Only assemble residual equations, do not assemble the Jacobians. Can save some assembly time if only the values are required.

- ‘iterations’ – Nonlinear iteration number. Special logic happens in the wells if it is the first iteration.

Returns: - problem – LinearizedProblemAD class instance, containing the equation for the water pressure, as well as well equations specified by the WellModel class.

- state – Updated state. Primarily returned to handle changing well controls from the well model.

See also

equationsBlackOil, ThreePhaseBlackOilModel

-

equationsWaterThermal(state0, state, model, dt, drivingForces, varargin)¶ Get linearized problem for single phase water system with black oil-style properties

-

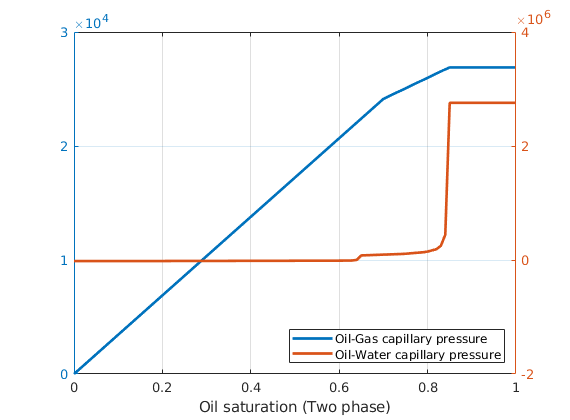

getCapillaryPressureBO(fluid, sW, sG)¶ Compute oil-water and oil-gas capillary pressures

Synopsis:

[pcOW, pcOG] = getCapillaryPressureBO(f, sW, sG)

Description:

Compute the capillary pressures relative to the oil pressure

Parameters: - fluid – AD fluid model, from for example initDeckADIFluid or initSimpleADIFluid.

- sW – Water saturation. Used to evaluate the water-oil capillary pressure.

- sG – Gas saturation. Used to evaluate the oil-gas capillary pressure.

Returns: - pcOW – Pressure difference between the oil and water pressures. The water phase pressure can be computed as pW = pO - pcOW;

- pcOG – Pressure difference between the oil and gas pressures. The water phase pressure can be computed as pG = pO + pcOG;

Note

Mind the different sign for the computation of the phase pressures above!

-

getCellStatusVO(sO, sW, sG, varargin)¶ Get status flags for each cell in a black-oil model

Synopsis:

st = getCellStatusVO(model, state, sO, sW, sG)

Description:

Get the status flags for the number of phases present.

Parameters: - sO – Oil saturation. One value per cell in the simulation grid.

- sW – Water saturation. One value per cell in the simulation grid.

- sG – Gas saturation. One value per cell in the simulation grid.

Keyword Arguments: - status – status that can be provided fom the state for which the status flags are to be computed.

- vapoil – true if there can be vaporized oil

- disgas – true if there can be dissolved gas

Returns: st –

- Cell array with three columns with one entry per cell. The

interpretation of each flag:

Col 1: A cell is flagged as true if oil is present, but gas is not present. Col 2: A cell is flagged as true if gas is present, but oil is not present. Col 3: A cell is flagged as true if both gas and oil are present and true three-phase flow is occuring.

See also

ThreePhaseBlackOilModel

-

getDeckEGG(varargin)¶ Get the parsed deck for the EGG model

-

getFluxAndPropsGas_BO(model, pO, sG, krG, T, gdz, rv, isSat)¶ Get flux and properties for the gas phase for a black-oil problem

Synopsis:

[vG, bG, mobG, rhoG, pG, upcg, dpG] = ... getFluxAndPropsOil_BO(model, pO, sG, krG, T, gdz, rv, isSat)

Description:

Utility function for evaluating mobilities, densities and fluxes for the gas phase in the black-oil (BO)-model

Parameters: - model – ThreePhaseBlackOil or derived subclass instance

- p – Oil phase pressure. One value per cell in simulation grid.

- sG – Gas phase saturation. One value per cell in simulation grid.

- krG – Gas phase relative permeability, possibly evaluated some three-phase relperm function. One value per cell in simulation grid.

- T – Transmissibility for the internal interfaces.

- gdz – Let dz be the gradient of the cell depths, on each interface.

- gdz is the dot product of the dz with the gravity vector of the (Then) –

- See getGravityGradient for more information. (model.) –

- rv – Amount of oil vaporized into the gas phase. Use to evaluate the viscosity and density. One value per cell in simulation grid.

- isSat – Boolean indicator if the gas in the cell is saturated with oil.

- indicates that the maximum vaporized gas is present inside the gas (True) –

- in the cell, and that we need to look at the saturated tables (phase) –

- evaluating rv (when) – dependent properties. One value per cell in

- grid. (simulation) –

Returns: - vG – Gas flux, at reservoir conditions, at each interface.

- bG – Gas reciprocal formation volume factors. One value per cell in simulation grid.

- rhoG – Gas density in each cell.

- pG – Gas phase pressure. One value per cell in simulation grid. Pressure will be different from the oil pressure if capillary pressure is present in the model.

- upcg – Upwind indicators for the gas phase. One value per interface.

- dpG – Phase pressure differential for each interface. Was used to evaluate the phase flux.

See also

getFluxAndPropsOil_BO, getFluxAndPropsWater_BO

-

getFluxAndPropsOil_BO(model, p, sO, krO, T, gdz, rs, isSat)¶ Get flux and properties for the oil phase for a black-oil problem

Synopsis:

[vO, bO, mobO, rhoO, p, upco, dpO] = ... getFluxAndPropsOil_BO(model, p, sO, krO, T, gdz, rs, isSat)

Description:

Utility function for evaluating mobilities, densities and fluxes for the oil phase in the black-oil (BO)-model

Parameters: - model – ThreePhaseBlackOil or derived subclass instance

- p – Oil phase pressure. One value per cell in simulation grid.

- sO – Oil phase saturation. One value per cell in simulation grid.

- krO – Oil phase relative permeability, possibly evaluated some three-phase relperm function. One value per cell in simulation grid.

- T – Transmissibility for the internal interfaces.

- gdz – Let dz be the gradient of the cell depths, on each interface.

- gdz is the dot product of the dz with the gravity vector of the (Then) –

- See getGravityGradient for more information. (model.) –

- rs – Amount of gas dissolved into the oil phase. Use to evaluate the viscosity and density. One value per cell in simulation grid.

- isSat – Boolean indicator if the oil in the cell is saturated with gas.

- indicates that there is free gas in the cell, and that we need to (True) –

- at the saturated tables when evaluating rs (look) – dependent properties.

- value per cell in simulation grid. (One) –

Returns: - vO – Oil flux, at reservoir conditions, at each interface.

- bO – Oil reciprocal formation volume factors. One value per cell in simulation grid.

- rhoO – Oil density in each cell.

- p – Oil phase pressure. One value per cell in simulation grid. Should be unmodified. Included simply to have parity with analogous gas and water functions.

- upco – Upwind indicators for the oil phase. One value per interface.

- dpO – Phase pressure differential for each interface. Was used to evaluate the phase flux.

See also

getFluxAndPropsGas_BO, getFluxAndPropsWater_BO

-

getFluxAndPropsWater_BO(model, pO, sW, krW, T, gdz)¶ Get flux and properties for the water phase for a black-oil problem

Synopsis:

[vW, bW, mobW, rhoW, pW, upcw, dpW] = ... getFluxAndPropsWater_BO(model, pO, sW, krW, T, gdz)

Description:

Utility function for evaluating mobilities, densities and fluxes for the water phase in the black-oil (BO)-model

Parameters: - model – ThreePhaseBlackOil or derived subclass instance

- pO – Oil phase pressure. One value per cell in simulation grid.

- sW – Water phase saturation. One value per cell in simulation grid.

- krW – Water phase relative permeability, possibly evaluated some three-phase relperm function. One value per cell in simulation grid.

- T – Transmissibility for the internal interfaces.

- gdz – Let dz be the gradient of the cell depths, on each interface.

- gdz is the dot product of the dz with the gravity vector of the (Then) –

- See getGravityGradient for more information. (model.) –

Returns: - vW – Water flux, at reservoir conditions, at each interface.

- bW – Water reciprocal formation volume factors. One value per cell in simulation grid.

- rhoW – Water density in each cell.

- pW – Water phase pressure. One value per cell in simulation grid. Pressure will be different from the oil pressure if capillary pressure is present in the model.

- upcw – Upwind indicators for the water phase. One value per interface.

- dpW – Phase pressure differential for each interface. Was used to evaluate the phase flux.

See also

getFluxAndPropsGas_BO, getFluxAndPropsOil_BO

-

getPolymerShearMultiplier(model, VW0, muWmult)¶ Compute the flux multiplier due to polymer shear thinning/thickening

Synopsis:

mult = getPolymerShearMultiplier(model, VW0, muWmult) [mult,VW] = getPolymerShearMultiplier(...) [mult,VW,iter] = getPolymerShearMultiplier(...)

Description:

The viscoisty of a polymer solution may be changed by the shear rate, which is related to the flow velocity. This function returns a flux multiplier mult, such that

vWsh = vW.*mult, and, vPsh = vP.*mult,where vWsh and vPsh are the shear modified fluxes for pure water and water with polymer, respectively.

- The input water face velocity is computed as

- VW = vW/(poro*area)

where poro is the average porosity between neighboring cells, and area is the face area.

Parameters: - model – Model structure

- VW0 – Water velocity on faces without shear thinning

- muWmult – Viscosity multiplier on faces

- iter – Number of non-linear iterations

Returns: - mult – Flux multiplier (reciprocal of the viscosity multiplier)

- VW – Water velocity as solution of nonlinear shear equation

-

getWellPolymer(W)¶ Undocumented Utility Function

-

getbG_BO(model, p, rv, isLiquid)¶ Utility function for evaluating the reciprocal gas formation volume factor function.

-

getbO_BO(model, p, rs, isSaturated)¶ Utility function for evaluating the reciprocal oil formation volume factor function.

-

updateStateBlackOilGeneric(model, state, problem, dx, drivingForces)¶ Generic update function for blackoil-like models

Synopsis:

state = updateStateBlackOilGeneric(model, state, problem, dx)

Description:

This is a relatively generic update function that can dynamically work out where increments should go based on the model implementation. It can be used for simple models or used as inspiration for more exotic models.

Presently handles either 2/3-phase with disgas/vapoil or n-phase without dissolution.

Parameters: - model – PhysicalModel subclass.

- state – State which is to be updated.

- problem – Linearized problem from which increments were obtained

- dx – Increments created by solving the linearized problem.

- drivingForces – Wells etc.

Returns: state – Updated state.

Examples¶

load modules¶

Generated from aquifertest.m

mrstModule add mrst-gui deckformat ad-props ad-core ad-blackoil

mrstVerbose true

gravity on

close all

run two test cases¶

datadir = getDatasetPath('aquifertest', 'download', true);

for icase = 1 : 2

fnroot = sprintf('2D_OILWATER_AQ_ECLIPSE_%d', icase);

fn = fullfile(datadir, [fnroot, '.DATA']);

[model, initState, schedule] = setupAquifertest(fn);

[wellSols, states, schedulereport] = simulateScheduleAD(initState, model, ...

schedule);

statesEcl = loadAquiferEclipseResult(datadir, fnroot);

No converter needed in section 'REGIONS'.

No converter needed in section 'SUMMARY'.

Adding 40 artificial cells at top/bottom

Processing regular i-faces

Found 144 new regular faces

Elapsed time is 0.018308 seconds.

...

No converter needed in section 'REGIONS'.

No converter needed in section 'SUMMARY'.

Adding 40 artificial cells at top/bottom

Processing regular i-faces

Found 144 new regular faces

Elapsed time is 0.007527 seconds.

...

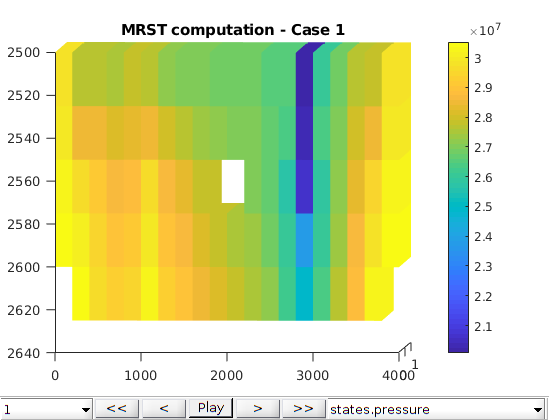

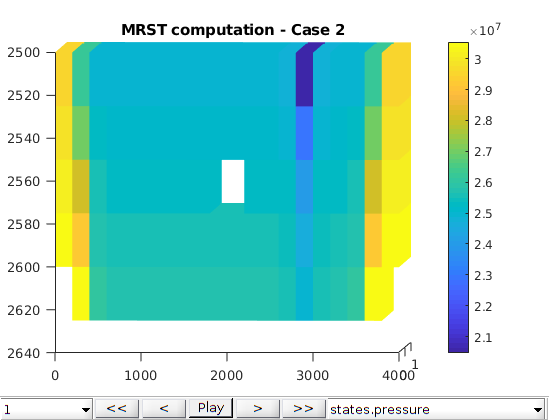

plots¶

G = model.G;

figure

plotToolbar(G, states);

view([2, 2]);

colorbar

title(sprintf('MRST computation - Case %d', icase));

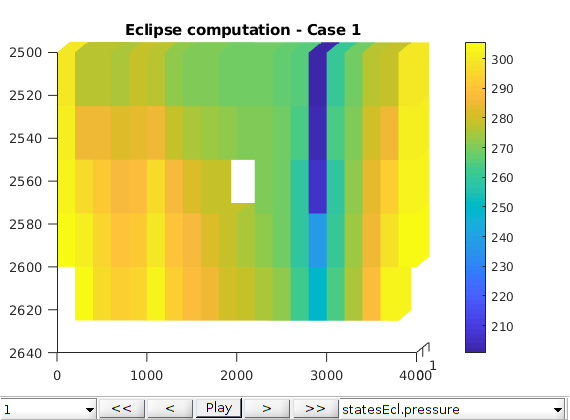

figure

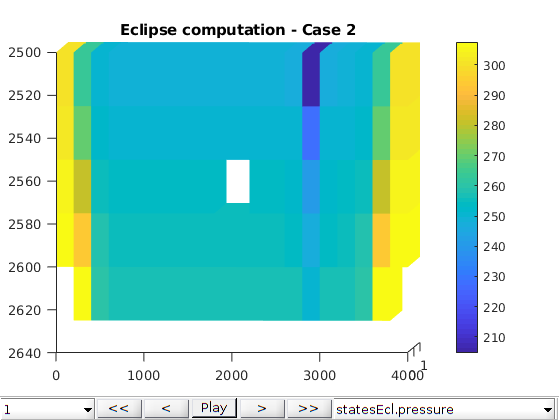

plotToolbar(G, statesEcl);

view([2, 2]);

colorbar

title(sprintf('Eclipse computation - Case %d', icase));

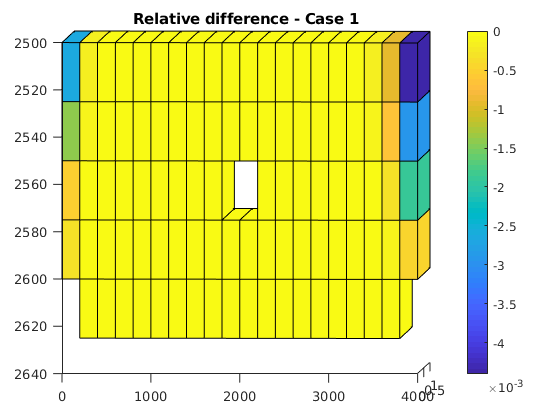

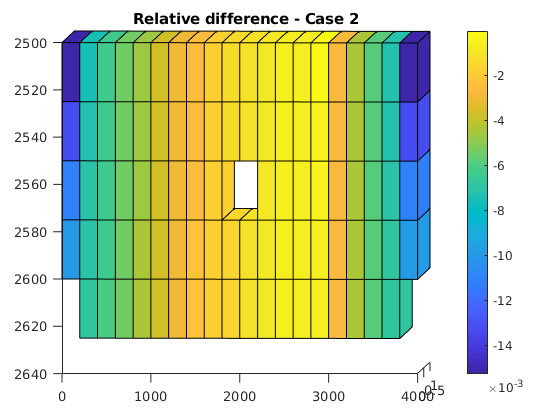

p = states{end}.pressure;

pecl = statesEcl{end}.pressure;

pecl = pecl*barsa;

err = (p - pecl)./pecl;

figure

plotCellData(G, err);

view([2, 2]);

colorbar

title(sprintf('Relative difference - Case %d', icase));

nd

% <html>

% <p><font size="-1

Example demonstrating use of boundary conditions for pressure support¶

Generated from blackoilSectorModelExample.m

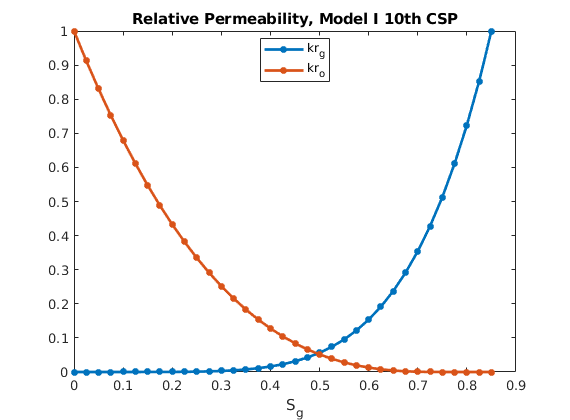

We take the SPE1 fluid model to get a simple blackoil-model. We make the aqueous phase mobile by manually setting the relative permeability.

mrstModule add ad-core ad-blackoil ad-props

[~, ~, fluid, deck] = setupSPE1();

fluid.krW = @(s) s.^2;

No converter needed in section 'REGIONS'.

No converter needed in section 'SUMMARY'.

Adding 200 artificial cells at top/bottom

Processing regular i-faces

Found 550 new regular faces

Elapsed time is 0.001533 seconds.

...

Set up a simple grid with an initial state¶

We create a small grid with initial water and oil saturation, as well as a Rs (dissolved gas in oil-ratio) of 200. This undersaturated reservoir does not have any free gas.

G = cartGrid([50, 50, 1], [1000, 1000, 100]*meter);

G = computeGeometry(G);

rock = makeRock(G, 0.3*darcy, 0.3);

% Define initial composition and pressure

s0 = [0.2, 0.8, 0];

p0 = 300*barsa;

state0 = initResSol(G, p0, s0);

state0.rs = repmat(200, G.cells.num, 1);

% Black oil with disgas

model = ThreePhaseBlackOilModel(G, rock, fluid, 'disgas', true);

Processing Cells 1 : 2500 of 2500 ... done (0.02 [s], 1.16e+05 cells/second)

Total 3D Geometry Processing Time = 0.022 [s]

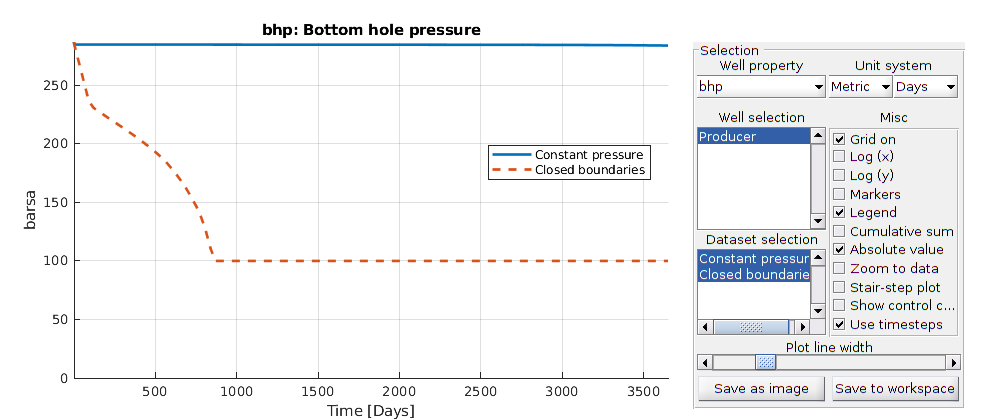

Set up driving forces¶

We will operate a single producer well at a fixed rate. In addition, we define a set of boundary conditions at the vertical boundary of the domain with a fixed pressure and composition equal to the initial values of the reservoir itself.

% Time horizon

T = 10*year;

% Produce 1/4 PV at surface conditions controlled by oil rate

ij = ceil(G.cartDims./2);

W = verticalWell([], G, rock, ij(1), ij(2), [], ...

'val', -0.25*sum(model.operators.pv)/T, ...

'type', 'orat',...

'comp_i', [1, 1, 1]/3, ...

'sign', -1, ...

'name', 'Producer');

% Define a lower bhp limit so that we have a lower bound on the reservoir

% pressure during the simulation.

W.lims.bhp = 100*barsa;

% Define boundary conditions

bc = [];

sides = {'xmin', 'xmax', 'ymin', 'ymax'};

for side = 1:numel(sides)

bc = pside(bc, G, sides{side}, p0, 'sat', s0);

end

% We define initial Rs value for the BC. We can either supply a single

% value per interface or one for all interfaces. In this case, we supply a

% single value for all interfaces since there is no variation in the

% initial conditions.

%

% To define dissolution per face, a matrix of dimensions numel(bc.face)x3x3

% would have to be set.

bc.dissolution = [1, 0, 0;...

% Water fractions in phases

0, 1, 0; ...% Oil fractions in phases

0, 200, 1]; % Gas fractions in phases

% Simple uniform schedule with initial rampup

dt = rampupTimesteps(T, 30*day);

% Define schedule with well and constant pressure boundary conditions

schedule = simpleSchedule(dt, 'W', W, 'bc', bc);

[ws, states] = simulateScheduleAD(state0, model, schedule);

% Define schedule with well and closed boundaries

schedule2 = simpleSchedule(dt, 'W', W, 'bc', []);

[ws_c, states_c] = simulateScheduleAD(state0, model, schedule2);

Defaulting reference depth to top of formation for well Producer. Please specify 'refDepth' optional argument to 'addWell' if you require bhp at a specific depth.

*****************************************************************

********** Starting simulation: 130 steps, 3650 days *********

*****************************************************************

Preparing model for simulation...

Model ready for simulation...

Preparing schedule for simulation...

Schedule ready for simulation...

...

Compare the two results¶

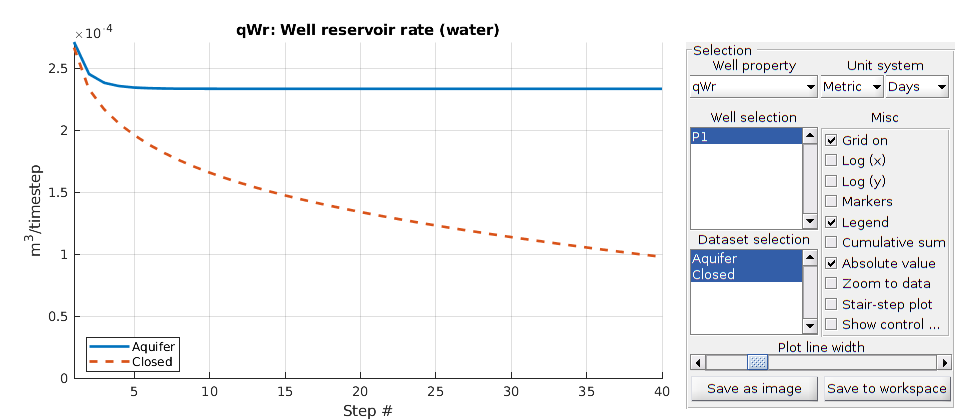

We observe that the simulation with constant boundary pressure has a very different pressure build up than the same problem with closed boundaries. Note also that once the bhp limit is reached, the well switches controls in the closed model, and the oil production rate changes.

plotWellSols({ws, ws_c}, cumsum(schedule.step.val), ...

'datasetnames', {'Constant pressure', 'Closed boundaries'})

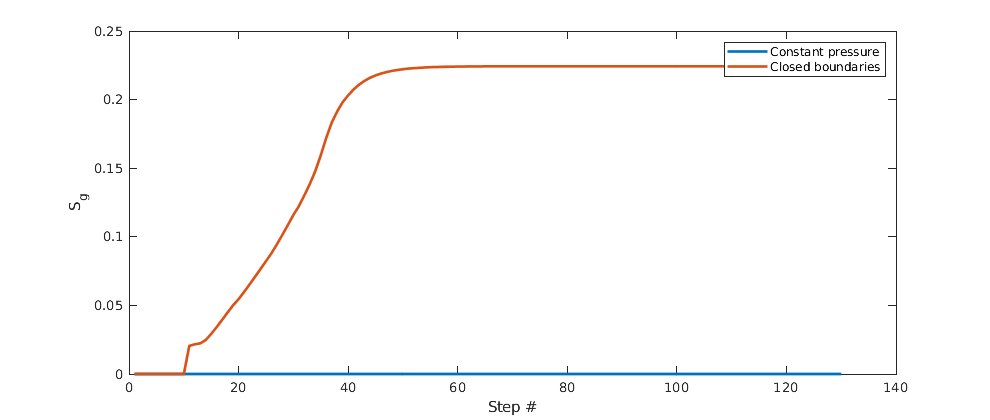

Plot the gas in the well cells¶

If we do not have open boundaries, the pressure will eventually drop as a result of the large removed volumes of oil and dissolved gas. For the model with closed boundaries, we get drop-out of free gas.

as_open = cellfun(@(x) x.s(W.cells(1), 3), states);

gas_closed = cellfun(@(x) x.s(W.cells(1), 3), states_c);

clf;

plot([gas_open, gas_closed], 'linewidth', 2)

ylabel('S_g')

xlabel('Step #');

legend('Constant pressure', 'Closed boundaries');

% <html>

% <p><font size="-1

mrstModule add ad-core ad-blackoil deckformat ad-props linearsolvers

mrstVerbose on

[G, rock, fluid, deck, state] = setupSPE1();

[state0, model, schedule] = initEclipseProblemAD(deck);

No converter needed in section 'REGIONS'.

No converter needed in section 'SUMMARY'.

Adding 200 artificial cells at top/bottom

Processing regular i-faces

Found 550 new regular faces

Elapsed time is 0.006345 seconds.

...

Fully-implicit¶

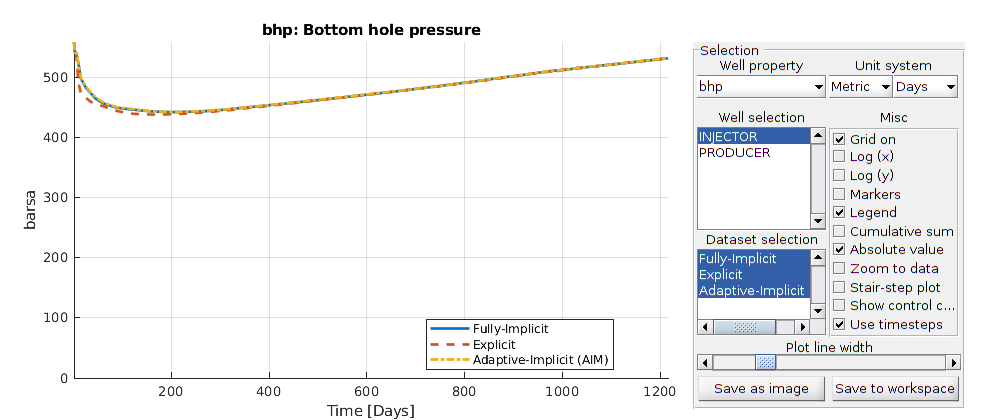

Generated from blackoilTimeIntegrationExample.m

The default discretization in MRST is fully-implicit. Consequently, we can use the model as-is.

implicit = packSimulationProblem(state0, model, schedule, 'SPE1_ex', 'Name', 'Fully-Implicit');

Explicit solver¶

This solver has a time-step restriction based on the CFL condition in each cell. The solver estimates the time-step before each solution.

model_explicit = model.validateModel();

% Get the flux discretization

flux = model_explicit.FluxDiscretization;

% Use explicit form of flow state

fb = ExplicitFlowStateBuilder();

flux = flux.setFlowStateBuilder(fb);

model_explicit.FluxDiscretization = flux;

explicit = packSimulationProblem(state0, model_explicit, schedule, 'SPE1_ex', 'Name', 'Explicit');

Adaptive implicit¶

We can solve some cells implicitly and some cells explicitly based on the local CFL conditions. For many cases, this amounts to an explicit treatment far away from wells or driving forces. The values for estimated composition CFL and saturation CFL to trigger a switch to implicit status can be adjusted.

model_aim = model.validateModel();

flux = model_aim.FluxDiscretization;

fb = AdaptiveImplicitFlowStateBuilder();

flux = flux.setFlowStateBuilder(fb);

model_aim.FluxDiscretization = flux;

aim = packSimulationProblem(state0, model_aim, schedule, 'SPE1_ex', 'Name', 'Adaptive-Implicit (AIM)');

Simulate the problems¶

problems = {implicit, explicit, aim};

simulatePackedProblem(problems);

*******************************************************

* Case "SPE1_ex" (Fully-Implicit) *

* Description: "Fully-Implicit_GenericBlackOilModel" *

*******************************************************

-> Complete output found, nothing to do here.

*************************************************

* Case "SPE1_ex" (Explicit) *

...

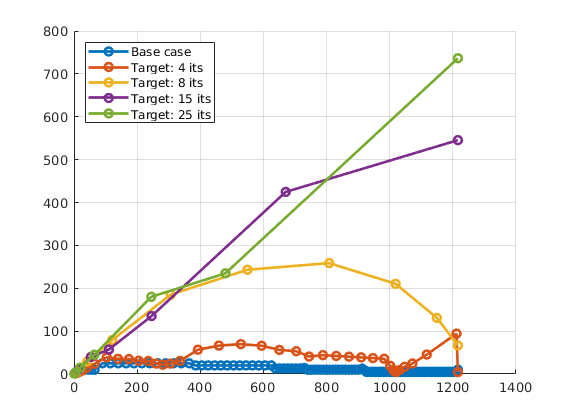

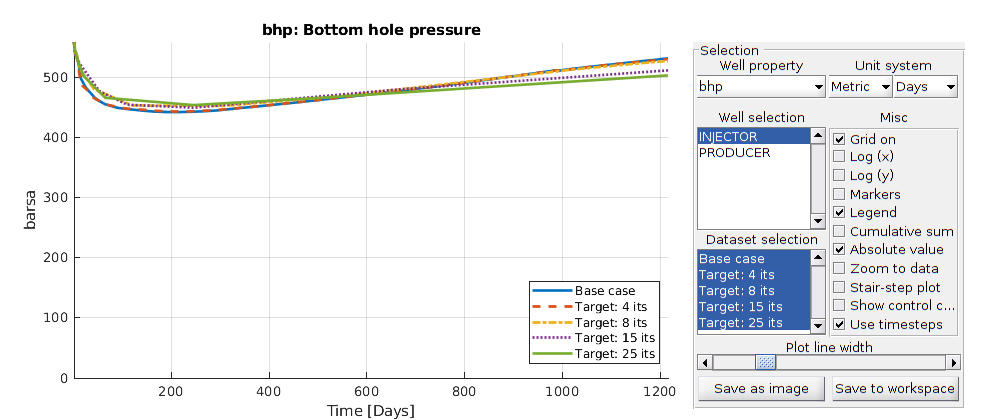

Get output and plot the well results¶

There are oscillations in the well curves. Increasing the CFL limit beyond unity will eventually lead to oscillations.

[ws, states, reports, names, T] = getMultiplePackedSimulatorOutputs(problems);

plotWellSols(ws, T, 'datasetnames', names);

Found complete data for SPE1_ex (Fully-Implicit): 120 steps present

Found complete data for SPE1_ex (Explicit): 120 steps present

Found complete data for SPE1_ex (Adaptive-Implicit (AIM)): 120 steps present

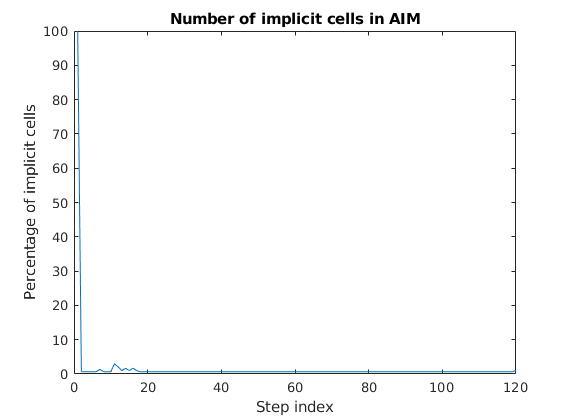

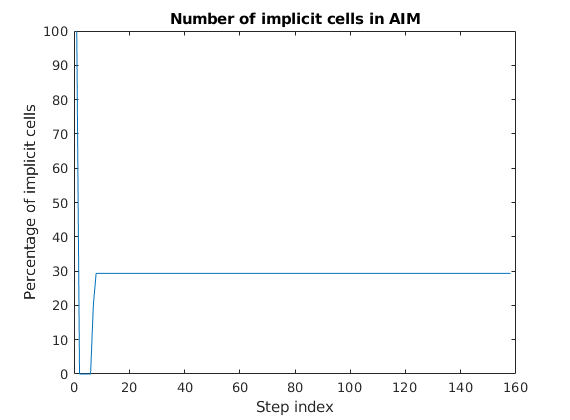

Plot the fraction of cells which are implicit¶

imp_frac = cellfun(@(x) sum(x.implicit)/numel(x.implicit), states{3});

figure;

plot(100*imp_frac);

title('Number of implicit cells in AIM')

ylabel('Percentage of implicit cells')

xlabel('Step index')

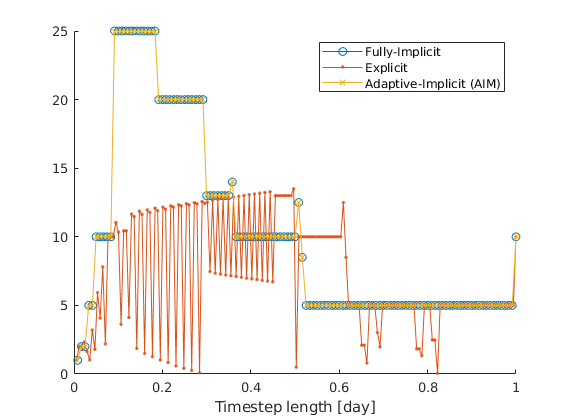

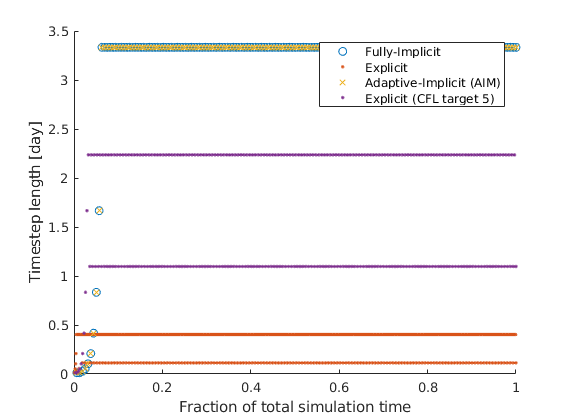

Plot the time-steps taken¶

The implicit solvers use the control steps while the explicit solver must solve many substeps.

igure; hold on

markers = {'o', '.', 'x'};

for i = 1:numel(reports)

dt = getReportMinisteps(reports{i});

x = (1:numel(dt))/numel(dt);

plot(x, dt/day, 'marker', markers{i})

end

xlabel('Timestep length [day]')

legend(names)

% <html>

% <p><font size="-1

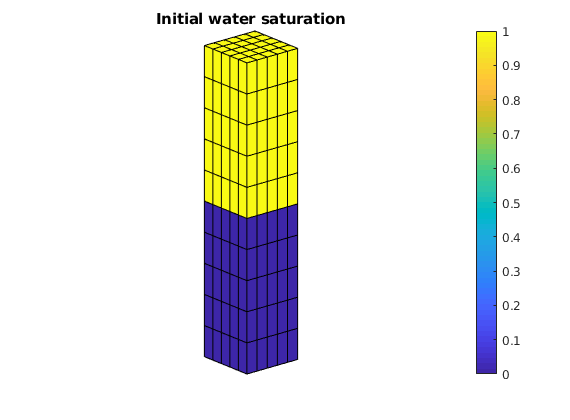

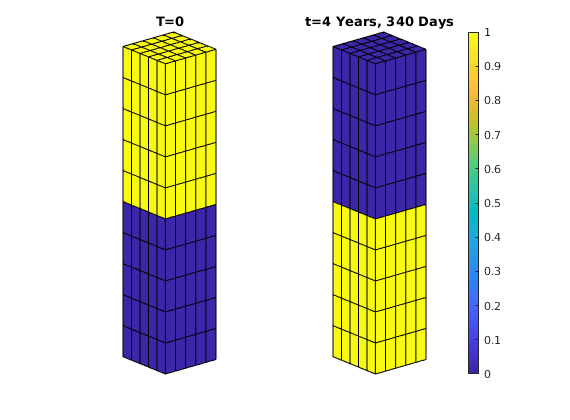

Gravity segregation using two phase AD solvers¶

Generated from blackoilTutorialGravSeg.m

This example demonstrates a simple, but classical test problem for a multiphase solver. The problem we are considering is that of gravity segregation: For a given domain, we let the initial fluid distribution consist of a dense fluid atop of a lighter one. Gravity is the only active force, and bouyancy will over time force the reservoir towards a stable equilibrium in which the denser fluid has switched place with the lighter fluid. The example also demonstrates how to set up a simple schedule (one or more timesteps with a collection of driving forces such as bc and wells).

mrstModule add ad-core ad-blackoil ad-props mrst-gui

Reservoir geometry and petrophysical properties¶

We begin by defining a simple homogenous reservoir of 1 by 1 by 5 meters and 250 simulation cells.

dims = [5 5 10];

G = cartGrid(dims, [1, 1, 5]*meter);

G = computeGeometry(G);

rock = makeRock(G, 100*milli*darcy, 0.5);

Processing Cells 1 : 250 of 250 ... done (0.00 [s], 6.98e+04 cells/second)

Total 3D Geometry Processing Time = 0.004 [s]

Defining the fluid properties¶

In this section, we set up a generic fluid suitable for solvers based on automatic differentiation. The fluid model is by default incompressible. We define two phases: Oil and water with significant differences in density and viscosity.

fluid = initSimpleADIFluid('phases', 'WO', ...

'mu', [1, 10]*centi*poise, ...

'n', [1, 1], ...

'rho', [1000, 700]*kilogram/meter^3);

Defining the model¶

The model object contains all functions necessary to simulate a mathematical model using the AD-solvers. In our case, we are interested in a standard fully implicit two-phase oil/water model. By passing the grid, rock, and fluid into the model constructor we obtain a model with precomputed operators and quantities that can be passed on to the simulator. We also ensure that gravity is enabled before we call the constructor.

gravity reset on

model = TwoPhaseOilWaterModel(G, rock, fluid);

% Show the model

disp(model)

TwoPhaseOilWaterModel with properties:

disgas: 0

vapoil: 0

drsMaxRel: Inf

drsMaxAbs: Inf

fluid: [1×1 struct]

rock: [1×1 struct]

...

Set up initial state¶

We must also define the initial state. The state contains the unstable initial fluid distribution. We do this by setting the water saturation to 1 in all cells and then setting it to zero in cells below a datum point. We defined the water (first phase) density to be 1000 kg/m^3 when we set up the fluid model. Note that we let the pressure be uniform initially. The model is relatively simple, so we do not need to worry about the initial pressure being reasonable, but this is something that should be considered more carefullly for models with e.g., compressibility. To ensure that we got the distribution right, we make a plot of the initial saturation.

[ii, jj, kk] = gridLogicalIndices(G);

lower = kk > 5;

sW = ones(G.cells.num, 1);

sW(lower) = 0;

s = [sW, 1 - sW];

% Finally set up the state

state = initResSol(G, 100*barsa, s);

% Plot the initial water saturation

figure;

plotCellData(G, state.s(:, 1))

axis equal tight off

view(50, 20)

title('Initial water saturation')

colorbar, drawnow

Set up boundary conditions and timesteps¶

Finally, we add a simple boundary condition of 100 bar pressure at the bottom of the reservoir. This is not strictly required, but the incompressible model will produce singular linear systems if we do not fix the pressure somehow. It is well known that the pressure is not unique for an incompressible model if there are no Dirichlet boundary conditions, as multiple pressures will give the same velocity field. Another alternative would be to add (some) compressibility to our fluid model. Once we have set up the boundary conditions, we define 20 timesteps of 90 days each, which is enough for the state to approach equilibrium. The simulator will cut timesteps if they do not converge, so we are not overly worried about the large initial timestep when the problem is the most stiff. Finally, we combine the timesteps and the boundary conditions into a schedule. A schedule collects multiple timesteps into a single struct and makes it easier to have for example different boundary conditions at different time periods. For this example, however, the schedule is very simple.

bc = [];

bc = pside(bc, G, 'ZMin', 100*barsa, 'sat', [0 1]);

dt = repmat(90*day, 20, 1);

schedule = simpleSchedule(dt, 'bc', bc);

Simulate the problem¶

Finally, we simulate the problem. We note that the three simple objects define the entire simulation: - state defines the initial values in the reservoir - model defines the partial differential equations, their physical constraints and the numerical discretizations required to advance from one time to the next. - schedule defines any time dependent input parameters as well as the timesteps.

[wellSols, states] = simulateScheduleAD(state, model, schedule, 'Verbose', true);

*****************************************************************

********** Starting simulation: 20 steps, 1800 days *********

*****************************************************************

Preparing model for simulation...

Model ready for simulation...

Preparing schedule for simulation...

Schedule ready for simulation...

Validating initial state...

...

Plot the segregation process¶

We finish by plotting the water saturation at each timestep, showing how the lighter fluid migrates upward and the heavier fluid downward.

colorbar off; title('T=0');

set(gca,'Position',[.13 .11 .335 .815]); subplot(1,2,2);

for i = 1:numel(states)

%figure(h); clf;

% Neat title

str = ['t=', formatTimeRange(sum(dt(1:i)))];

% Plotting

plotCellData(G, states{i}.s(:, 1))

title(str)

% Make axis equal to show column structure

axis equal tight off

view(50, 20)

colorbar

caxis([0, 1])

drawnow, pause(0.2)

end

Copyright notice¶

<html>

% <p><font size="-1

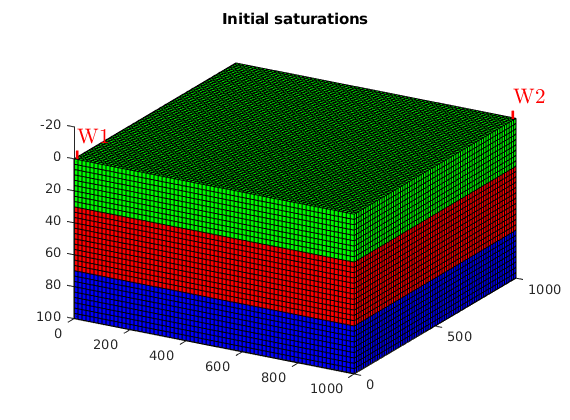

Example demonstrating accelerated assembly for faster simulation¶

Generated from blackoilTutorialMexAcceleration.m

Running larger cases in MRST is possible, but the default parameters of MRST’s solvers are optimized for ease-of-use out of the box with just a standard Matlab installation. We do not wish to require users to have C++ compilers, external software or expensive add-on toolboxes to make use of the software. However, simulation can be achieved much faster if one has access to both - A C++ compiler - An external linear solver with a Matlab interface. This examples demonstrates the use of MEX to seamlessly improve assembly speed for AD-solvers.

mrstModule add ad-core ad-blackoil deckformat ad-props linearsolvers

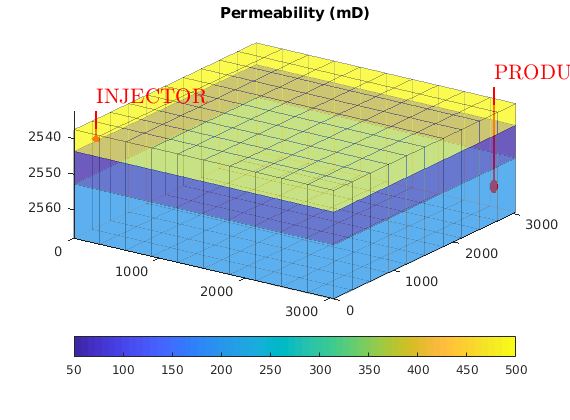

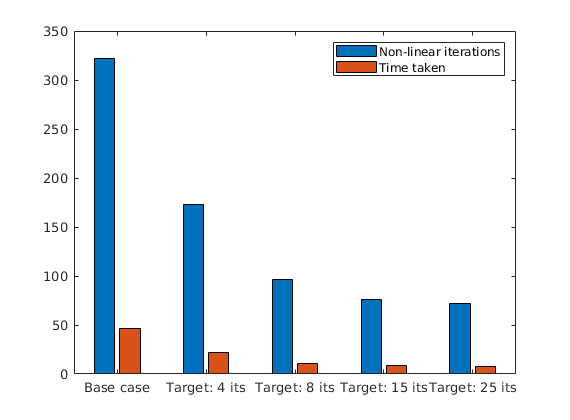

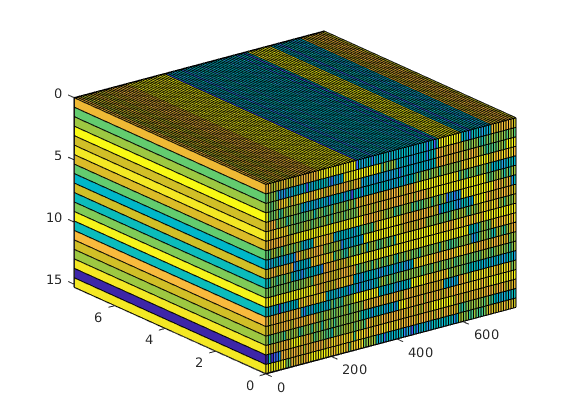

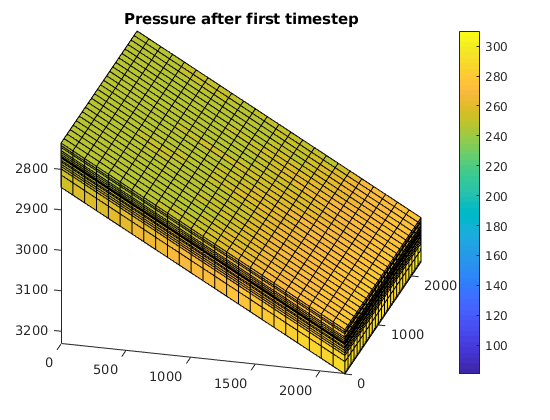

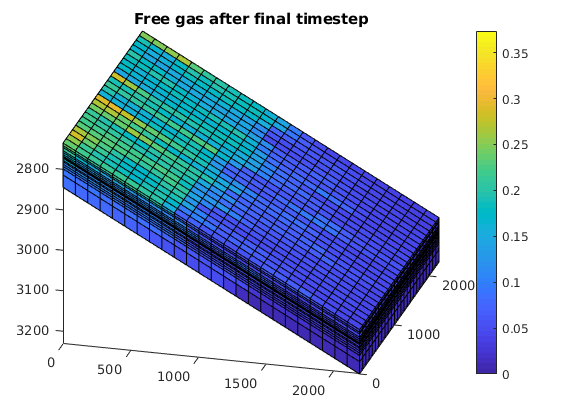

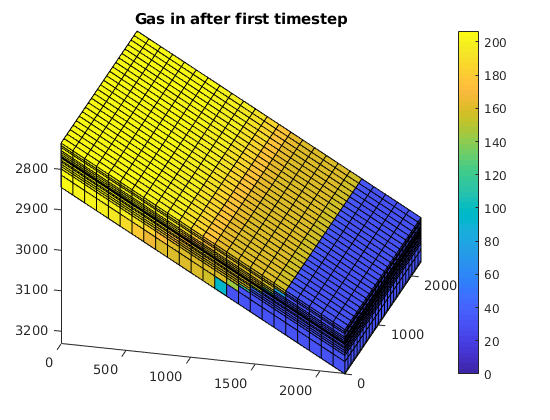

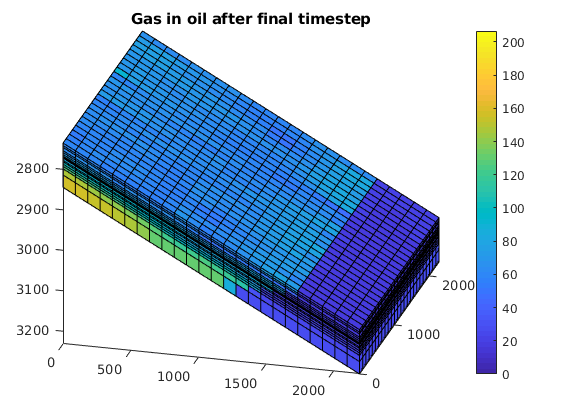

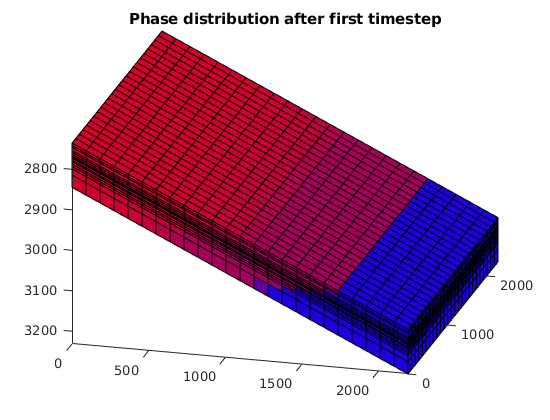

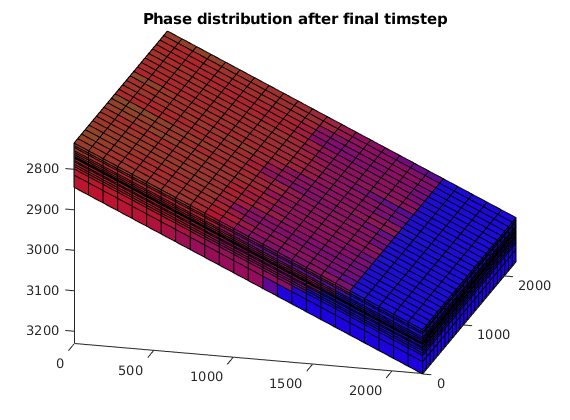

Define a 70x70x30 grid with uniform properties¶

Obviously, you can adjust this to test your setup

dims = [70, 70, 30];

pdims = [1000, 1000, 100]*meter;

G = cartGrid(dims, pdims);

G = computeGeometry(G);

rock = makeRock(G, 0.1*darcy, 0.3);

Processing Cells 1 : 18375 of 147000 ... done (0.16 [s], 1.14e+05 cells/second)

Processing Cells 18376 : 36750 of 147000 ... done (0.14 [s], 1.33e+05 cells/second)

Processing Cells 36751 : 55125 of 147000 ... done (0.14 [s], 1.34e+05 cells/second)

Processing Cells 55126 : 73500 of 147000 ... done (0.14 [s], 1.33e+05 cells/second)

Processing Cells 73501 : 91875 of 147000 ... done (0.14 [s], 1.33e+05 cells/second)

Processing Cells 91876 : 110250 of 147000 ... done (0.14 [s], 1.32e+05 cells/second)

Processing Cells 110251 : 128625 of 147000 ... done (0.14 [s], 1.34e+05 cells/second)

Processing Cells 128626 : 147000 of 147000 ... done (0.14 [s], 1.34e+05 cells/second)

...

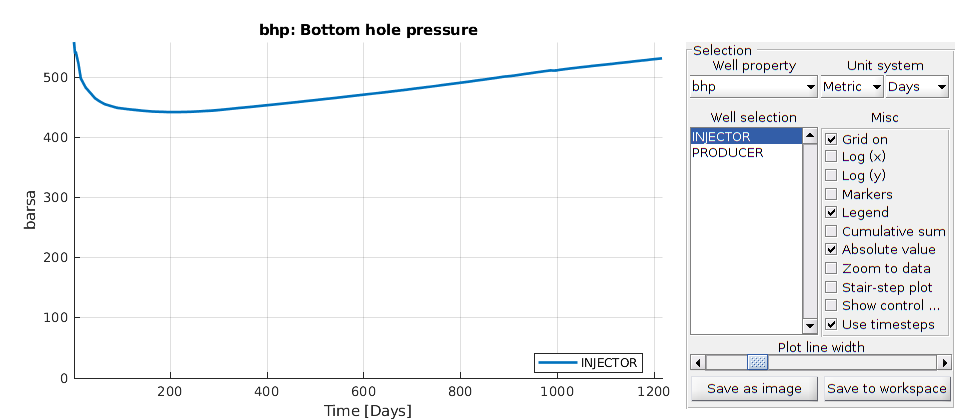

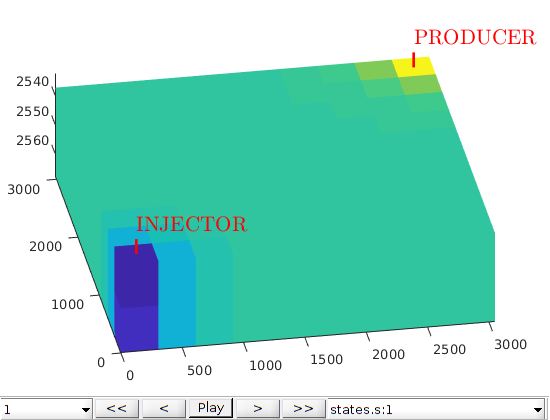

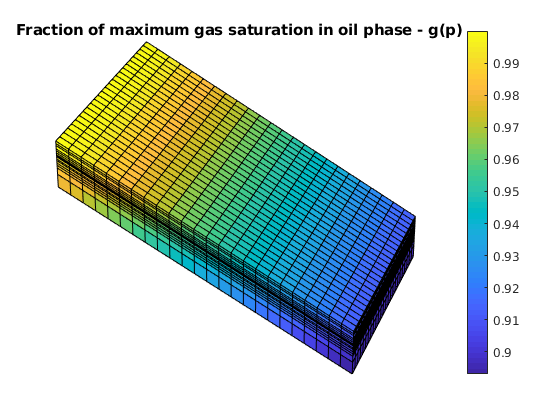

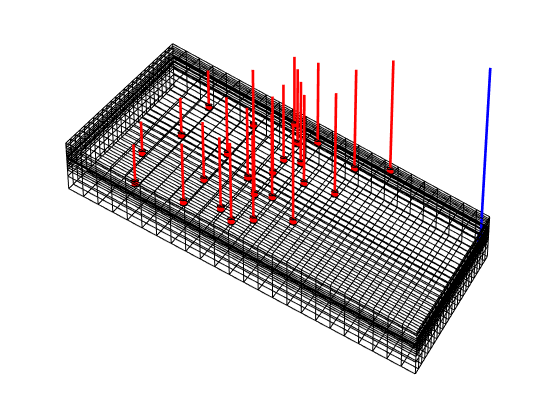

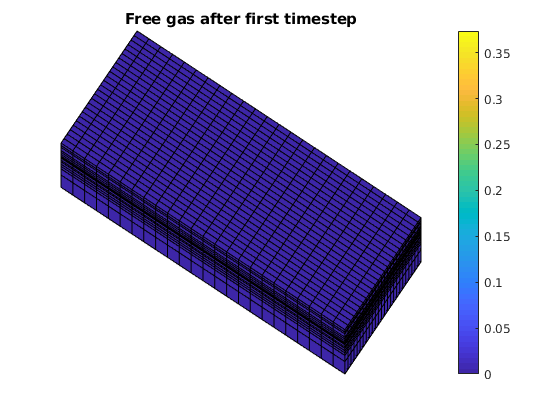

Set up QFS water injection scenario¶

As the point of this example is on how to set up the solvers, we just set up a simple injection scenario for a 3D quarter-five-spot problem.

gravity reset on

time = 10*year;

irate = 0.3*sum(poreVolume(G, rock)/time);

W = [];

W = verticalWell(W, G, rock, 1, 1, [], 'comp_i', [1, 0, 0], ...

'type', 'rate', 'val', irate);

W = verticalWell(W, G, rock, dims(1), dims(2), 1, 'comp_i', [1, 0, 0], ...

'type', 'bhp', 'val', 100*barsa);

Defaulting reference depth to top of formation for well W1. Please specify 'refDepth' optional argument to 'addWell' if you require bhp at a specific depth.

Defaulting reference depth to top of formation for well W2. Please specify 'refDepth' optional argument to 'addWell' if you require bhp at a specific depth.

Three-phase fluid model with compressibility and nonlinear flux¶

fluid = initSimpleADIFluid('n', [2, 3, 1], ...

'rho', [1000, 700, 10], ...

'mu', [1, 5, 0.1]*centi*poise, ...

'c', [0, 1e-6, 1e-4]/barsa);

Do 5 time-steps of 30 days each to test assembly speed¶

dt = repmat(30*day, 5, 1);

% Alternatively: Run the whole schedule with 200 time-steps.

% dt = rampupTimesteps(time, time/200);

schedule = simpleSchedule(dt, 'W', W);

model = GenericBlackOilModel(G, rock, fluid, 'disgas', false, 'vapoil', false);

Set up mex-accelerated backend and reduced variable set for wells¶

We use the Diagonal autodiff backend to calculate derivatives. By default, this uses only Matlab, so we also set the “useMex” flag to be true. It will then use C++ versions of most discrete operators during assembly.

model.AutoDiffBackend = DiagonalAutoDiffBackend('useMex', true);

model = model.validateModel();

model.FacilityModel.primaryVariableSet = 'bhp';

Run assembly tests (will compile backends if required)¶

Note: Benchmarks are obviously not accurate if compilation is performed.

testMexDiagonalOperators(model, 'block_size', 3);

********************************************************

* Face average

* Diagonal: 0.024513s, Diagonal-MEX: 0.013615s (1.80 speedup)

* Sparse: 0.018307s, Diagonal-MEX: 0.013615s (1.34 speedup)

Value error 0, Jacobian error 0

********************************************************

********************************************************

* Single-point upwind

...

Set up a compiled linear solver¶

We use a AMGCL-based CPR solver to solve the problem. It is sufficient to have a working C++ compiler, the AMGCL repository and BOOST available to compile it. See the documentation of amgcl_matlab for more details on how to set up these paths.

ncomp = model.getNumberOfComponents();

solver = AMGCL_CPRSolverAD('tolerance', 1e-3, 'block_size', ncomp, ...

'useSYMRCMOrdering', true, ...

'coarsening', 'aggregation', 'relaxation', 'ilu0');

nls = NonLinearSolver('LinearSolver', solver);

Set up initial state¶

We define fluid contacts and datum pressure

region = getInitializationRegionsBlackOil(model, [70, 30], 'datum_pressure', 200*barsa);

state0 = initStateBlackOilAD(model, region);

figure(1); clf

plotCellData(G, state0.s(:, [2, 3, 1]));

view(30, 30);

plotWell(G, W);

title('Initial saturations');

Run a serial simulation¶

maxNumCompThreads(1)

[ws0, states0, rep0] = simulateScheduleAD(state0, model, schedule, 'NonLinearSolver', nls);

ans =

8

*****************************************************************

********** Starting simulation: 5 steps, 150 days *********

*****************************************************************

...

Run a parallel simulation with four threads¶

maxNumCompThreads(4)

[ws, states, rep] = simulateScheduleAD(state0, model, schedule, 'NonLinearSolver', nls);

% Reset max number of threads

N = maxNumCompThreads('automatic');

ans =

1

*****************************************************************

********** Starting simulation: 5 steps, 150 days *********

*****************************************************************

...

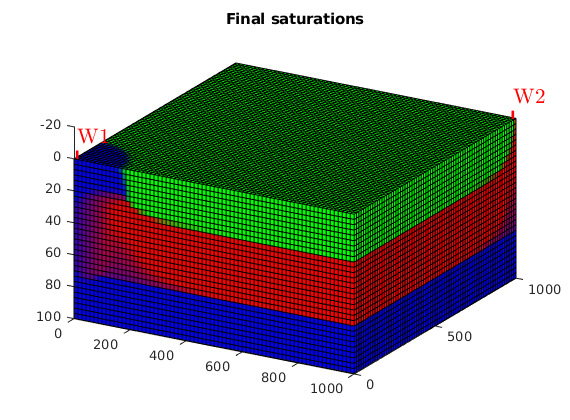

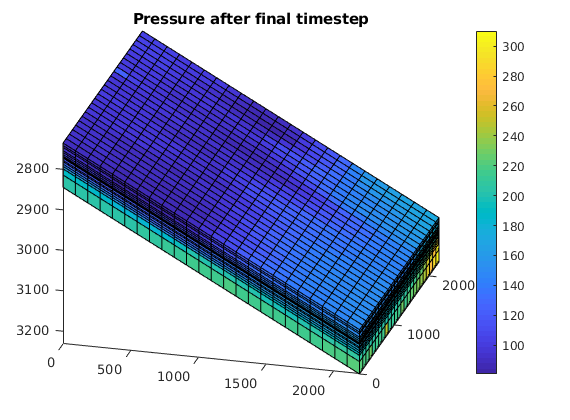

Plot the final saturations¶

figure(1); clf

plotCellData(G, states{end}.s(:, [2, 3, 1]));

view(30, 30);

plotWell(G, W);

title('Final saturations');

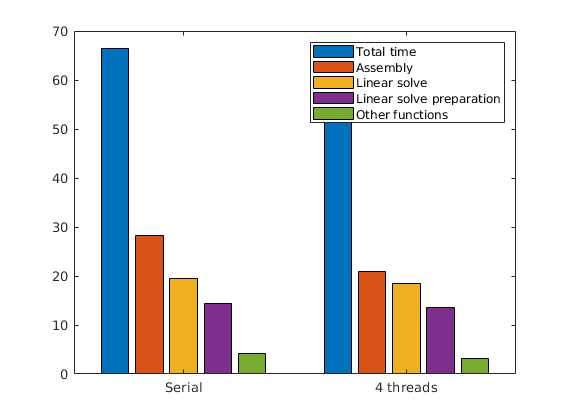

Plot timings¶

We plot the total time, the assembly (linearization) time, the linear solver time and the linear solver preparation time. The assembly and linear solver time are in general parallel, while the preparation is currently not. We likely observe that the linear solver is the place where most of the time is spent: Manipulating sparse matrices to fit them to an external solver can take significant time for a moderate-size problem.

serial = getReportTimings(rep0);

par = getReportTimings(rep);

total0 = sum(vertcat(serial.Total));

assembly0 = sum(vertcat(serial.Assembly));

lsolve0 = sum(vertcat(serial.LinearSolve));

lsolve_prep0 = sum(vertcat(serial.LinearSolvePrep));

its0 = rep0.Iterations;

total = sum(vertcat(par.Total));

assembly = sum(vertcat(par.Assembly));

lsolve = sum(vertcat(par.LinearSolve));

lsolve_prep = sum(vertcat(par.LinearSolvePrep));

its = rep.Iterations;

a = [total0, assembly0, lsolve0, lsolve_prep0];

b = [total, assembly, lsolve, lsolve_prep];

a(end+1) = a(1) - sum(a(2:end));

b(end+1) = b(1) - sum(b(2:end));

figure;

bar([a; b])

legend('Total time', 'Assembly', 'Linear solve', 'Linear solve preparation', 'Other functions')

set(gca, 'XTickLabel', {'Serial', [num2str(N), ' threads']})

Other notes¶

We note that the more degrees-of-freedom you have per cell in your model, the more efficient the MEX operators are compared to Matlab. See e.g. the compositional module’s example “compositionalLargerProblemTutorial.m” for another example benchmark.

<html>

% <p><font size="-1

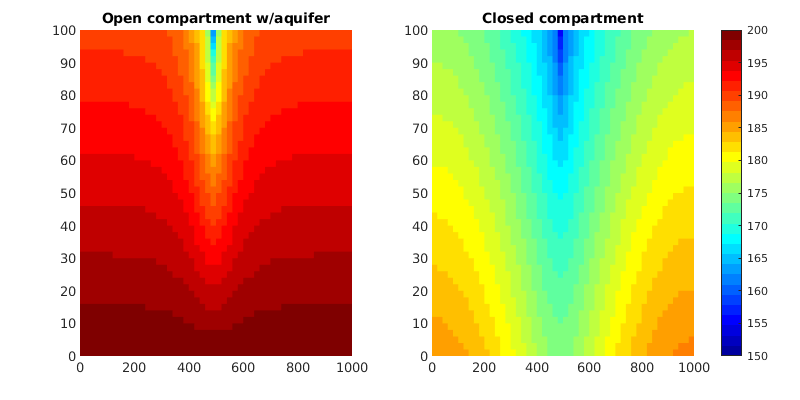

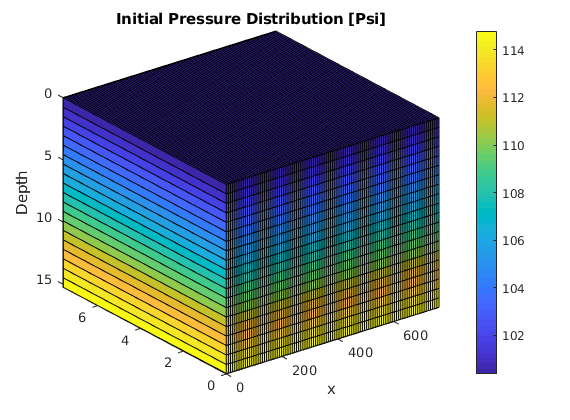

Example: Depletion of a closed or open reservoir compartment¶

Generated from blackoilTutorialOnePhase.m

In this tutorial, we will show how to set up a simulator from scratch in the automatic differentiation, object-oriented (AD-OO) framework without the use of input files. As an example we consider a 2D rectangular reservoir compartment with homogeneous properties, drained by a single producer at the midpoint of the top edge. The compartment is either closed (i.e., sealed by no-flow boundary conditions along all edges), or open with constant pressure support from an underlying, infinite aquifer, which we model as a constant-pressure boundary condition.

mrstModule add ad-props ad-core ad-blackoil

Grid, petrophysics, and fluid objects¶

To create a complete model object using the AD-OO framework, we first need to define three standard MRST structures representing the grid and the rock and fluid properties

% The grid and rock model

G = computeGeometry(cartGrid([50 50],[1000 100]));

rock = makeRock(G, 100*milli*darcy, 0.3);

% Fluid properties

pR = 200*barsa;

fluid = initSimpleADIFluid('phases','W', ...

% Fluid phase: water

'mu', 1*centi*poise, ...

% Viscosity

'rho', 1000, ...

% Surface density [kg/m^3]

'c', 1e-4/barsa, ...

% Fluid compressibility

'cR', 1e-5/barsa ...

% Rock compressibility

);

Computing normals, areas, and centroids... Elapsed time is 0.002116 seconds.

Computing cell volumes and centroids... Elapsed time is 0.007661 seconds.

Make Reservoir Model¶

We can now use the three objects defined above to instantiate the reservoir model. To this end, we will use a WaterModel, which is a specialization of the general ReservoirModel implemented in ad-core. The only extra thing we need to do is to explicitly set the gravity direction. By default, the gravity in MRST is a 3-component vector that points in the positive z-direction. Here, we set it to a 2-component vector pointing in the negative y-direction.

gravity reset on

wModel = WaterModel(G, rock, fluid,'gravity',[0 -norm(gravity)]);

% Prepare the model for simulation.

wModel = wModel.validateModel();

Drive mechansims and schedule¶

The second thing we need to specify is the mechanisms that will drive flow in the reservoir, i.e., the wells and boundary conditions. These may change over time and MRST therefore uses the concept of a schedule that describes how the drive mechansims change over time. In our case, we use the same setup for the whole simulation. The schedule also enables us to specify the time steps we wish the simulator to use, provided that these give convergent and stable computations. (If not, the simulator may cut the time step).

% Well: at the midpoint of the south edge

wc = sub2ind(G.cartDims, floor(G.cartDims(1)/2), G.cartDims(2));

W = addWell([], G, rock, wc, ...

'Type', 'bhp', 'Val', pR-50*barsa, ...

'Radius', 0.1, 'Name', 'P1','Comp_i',1,'sign',1);

% Boundary conditions: fixed pressure at bottom and no-flow elsewhere

bc=pside([],G,'South',200*barsa,'sat',1);

% Schedule: describing time intervals and corresponding drive mechanisms

schedule1 = simpleSchedule(diff(linspace(0,5*day,41)), 'bc', bc, 'W', W);

schedule2 = simpleSchedule(diff(linspace(0,5*day,41)), 'W', W);

Defaulting reference depth to top of formation for well P1. Please specify 'refDepth' optional argument to 'addWell' if you require bhp at a specific depth.

Reservoir state¶

The last component we need in order to specify our reservoir model is the reservoir state, i.e., the fluid pressure. For multiphase models, the state also includes the phase saturations and compositions. In our case, we first set a constant pressure, and call on a solver from ad-core to compute vertical equilibrium.

state = initResSol(G, pR); % Constant pressure

state.wellSol = initWellSolAD([], wModel, state); % No well initially

% Vertical equilibrium

verbose = false;

nonlinear = NonLinearSolver();

state = nonlinear.solveTimestep(state, 10000*day, wModel, 'bc', bc);

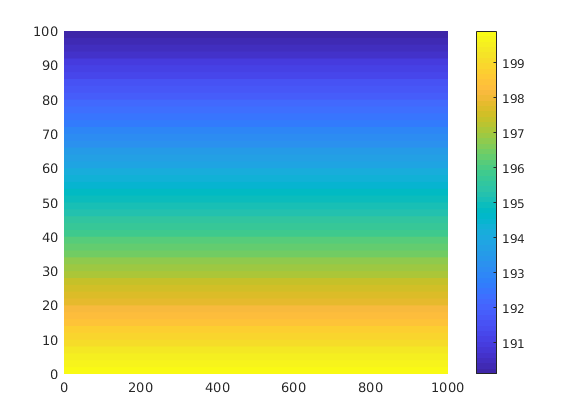

clf,

plotCellData(G,state.pressure/barsa,'EdgeColor','none');

colorbar

=======================

| It # | water (cell) |

=======================

| 1 | 2.01e-05 |

| 2 |*1.99e-08 |

=======================

Solved timestep with 1 accepted ministep (0 rejected, 1 total iteration)

Run simulations¶

To make the case a bit more interesting, we compute the flow problem twice. The first simulation uses the prescribed boundary conditions, which will enable fluids to pass out of the north boundary. In the second simulation, we close the system by imposing no-flow conditions also on the north boundary

% Simulation pressure 200 bar at top

[wellSols1, states1] = simulateScheduleAD(state, wModel, schedule1);

% Simulation with no-flow at top

[wellSols2, states2] = simulateScheduleAD(state, wModel, schedule2);

*****************************************************************

********** Starting simulation: 40 steps, 5 days *********

*****************************************************************

Preparing model for simulation...

Model ready for simulation...

Preparing schedule for simulation...

Schedule ready for simulation...

Validating initial state...

...

Plot results¶

Prepare animation

wpos = G.cells.centroids(wc,:); clf

set(gcf,'Position',[600 400 800 400])

h1 = subplot('Position',[.1 .11 .34 .815]);

hp1 = plotCellData(G,state.pressure/barsa,'EdgeColor','none');

title('Open compartment w/aquifer'); caxis([pR/barsa-50 pR/barsa]);

h2 = subplot('Position',[.54 .11 .4213 .815]);

hp2 = plotCellData(G,state.pressure/barsa,'EdgeColor','none');

title('Closed compartment'); caxis([pR/barsa-50 pR/barsa]);

colormap(jet(32)); colorbar

% Animate solutions by resetting CData property of graphics handle

for i=1:numel(states1)

set(hp1,'CData', states1{i}.pressure/barsa);

set(hp2,'CData', states2{i}.pressure/barsa);

drawnow, pause(0.1);

end

% Launch plotting of well responses

plotWellSols({wellSols1,wellSols2}, ...

'Datasetnames',{'Aquifer','Closed'}, 'field','qWr');

Copyright notice¶

<html>

% <p><font size="-1

Example demonstrating in-situ plotting capabilities in MRST-AD¶

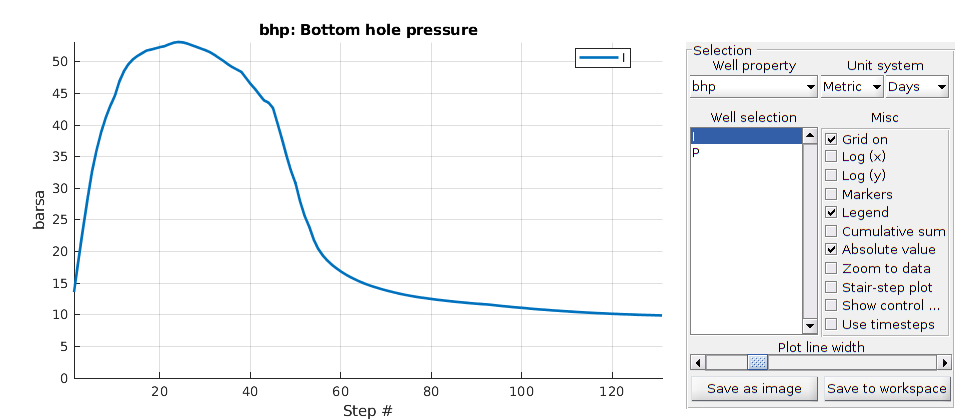

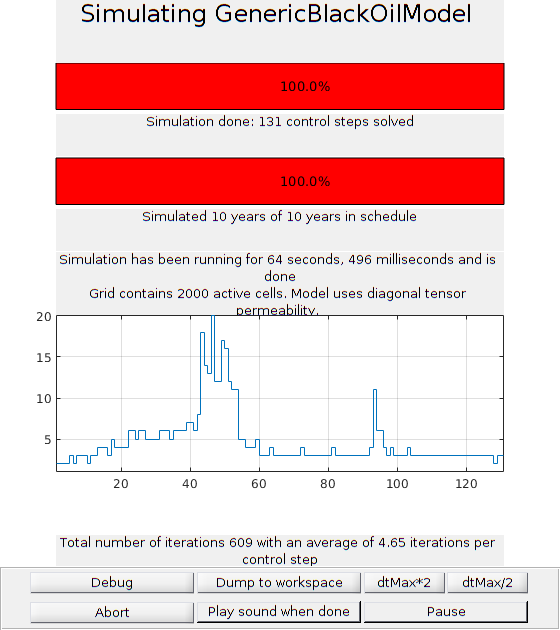

Generated from blackoilTutorialPlotHook.m

The AD-solvers allow for dynamic plotting during the simulation process. This example demonstrates this capability using “plotWellSols” and a panel showing simulation progress. We first set up a simulation model of SPE1 in the standard manner.

mrstModule add ad-core ad-blackoil ad-props mrst-gui deckformat

[G, rock, fluid, deck, state0] = setupSPE1();

model = selectModelFromDeck(G, rock, fluid, deck);

schedule = convertDeckScheduleToMRST(model, deck);

No converter needed in section 'REGIONS'.

No converter needed in section 'SUMMARY'.

Adding 200 artificial cells at top/bottom

Processing regular i-faces

Found 550 new regular faces

Elapsed time is 0.010813 seconds.

...

Set up plotting function¶

We set up a function handle that takes in the current simulator variables, which will be run after each succesful control step. This function can also pause the simulation or change the maximum timestep as a proof of concept.

close all

fn = getPlotAfterStep(state0, model, schedule, 'plotWell', true,...

'plotReservoir', false);

disp(fn)

@(model,states,reports,solver,schedule,simtime)afterStepFunction(model,states,reports,solver,schedule,simtime,injData,injectWell,hdata,hwell)

Run the simulation with plotting function¶

linsolve = selectLinearSolverAD(model);

[wellSols, states, report] = simulateScheduleAD(state0, model, schedule, ...

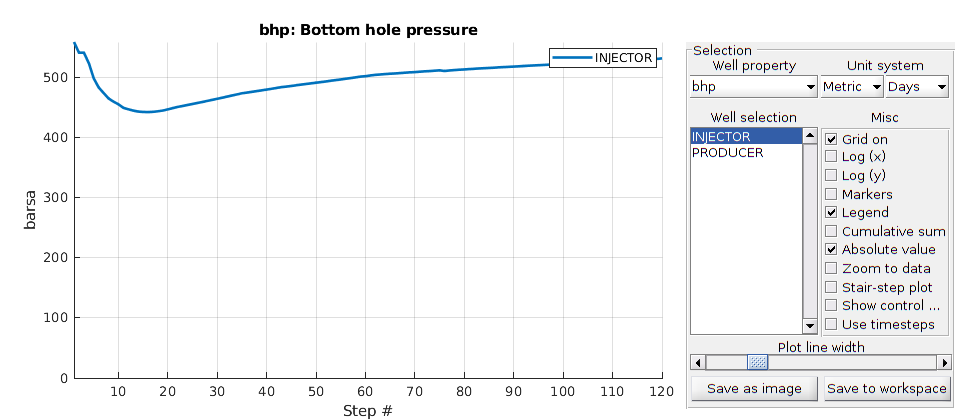

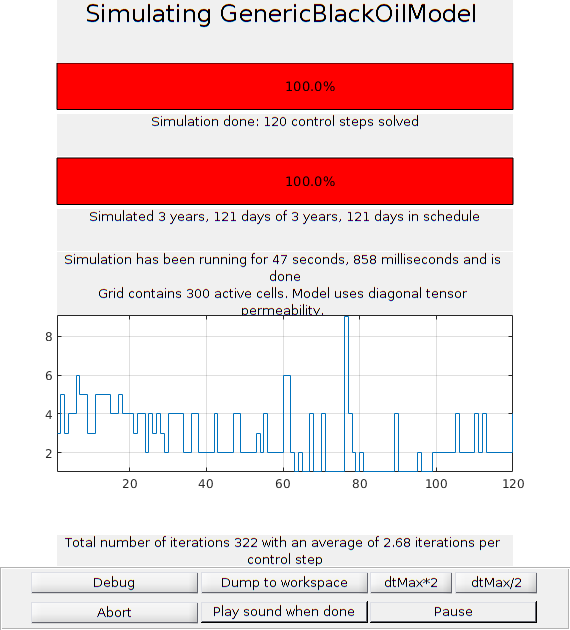

'Verbose', true, 'afterStepFn', fn, 'linearsolver', linsolve);

*****************************************************************

********** Starting simulation: 120 steps, 1216 days *********

*****************************************************************

Preparing model for simulation...

Model ready for simulation...

Preparing schedule for simulation...

Schedule ready for simulation...

Validating initial state...

...

Copyright notice¶

<html>

% <p><font size="-1

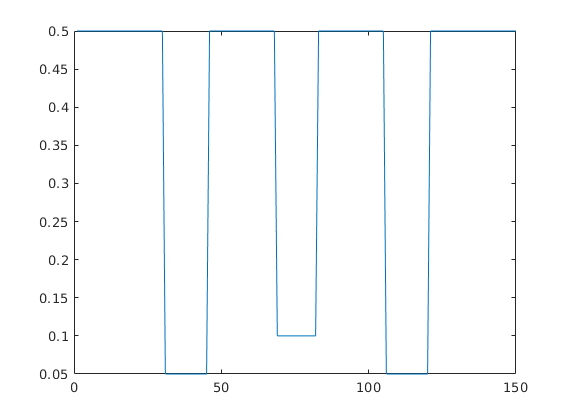

mrstModule add ad-core ad-blackoil deckformat ad-props linearsolvers

mrstVerbose on

L = 1000*meter;

G = cartGrid(150, L);

G = computeGeometry(G);

x = G.cells.centroids/L;

poro = repmat(0.5, G.cells.num, 1);

poro(x > 0.2 & x < 0.3) = 0.05;

poro(x > 0.7 & x < 0.8) = 0.05;

poro(x > 0.45 & x < 0.55) = 0.1;

rock = makeRock(G, 1*darcy, poro);

close all

plot(poro)

time = 500*day;

% Default oil-water fluid with unit values

fluid = initSimpleADIFluid('phases', 'WO', 'n', [1 1]);

% Set up model and initial state.

model = GenericBlackOilModel(G, rock, fluid, 'gas', false);

state0 = initResSol(G, 50*barsa, [0, 1]);

% Set up drive mechanism: constant rate at x=0, constant pressure at x=L

pv = poreVolume(G, rock);

injRate = sum(pv)/time;

bc = fluxside([], G, 'xmin', injRate, 'sat', [1, 0]);

bc = pside(bc, G, 'xmax', 0*barsa, 'sat', [0, 1]);

n = 150;

dT = time/n;

timesteps = rampupTimesteps(time, dT, 8);

schedule = simpleSchedule(timesteps, 'bc', bc);

Fully-implicit¶

Generated from immiscibleTimeIntegrationExample.m

The default discretization in MRST is fully-implicit. Consequently, we can use the model as-is.

implicit = packSimulationProblem(state0, model, schedule, 'immiscible_time', 'Name', 'Fully-Implicit');

Explicit solver¶

This solver has a time-step restriction based on the CFL condition in each cell. The solver estimates the time-step before each solution.

model_explicit = model.validateModel();

% Get the flux discretization

flux = model_explicit.FluxDiscretization;

% Use explicit form of flow state

fb = ExplicitFlowStateBuilder('Verbose', true);

fb.compositionCFL = inf;

flux = flux.setFlowStateBuilder(fb);

model_explicit.FluxDiscretization = flux;

explicit = packSimulationProblem(state0, model_explicit, schedule, 'immiscible_time', 'Name', 'Explicit');

Adaptive implicit¶

We can solve some cells implicitly and some cells explicitly based on the local CFL conditions. For many cases, this amounts to an explicit treatment far away from wells or driving forces. The values for estimated composition CFL and saturation CFL to trigger a switch to implicit status can be adjusted.

model_aim = model.validateModel();

flux = model_aim.FluxDiscretization;

fb = AdaptiveImplicitFlowStateBuilder('Verbose', true);

fb.compositionCFL = inf;

flux = flux.setFlowStateBuilder(fb);

model_aim.FluxDiscretization = flux;

aim = packSimulationProblem(state0, model_aim, schedule, 'immiscible_time', 'Name', 'Adaptive-Implicit (AIM)');

Make an explicit solver with larger CFL limit¶

Since the equation is linear, we can set the NonLinearSolver to use a single step. We bypass the convergence checks and can demonstrate the oscillations that result in taking a longer time-step than the stable limit.

model_explicit_largedt = model.validateModel();

% Get the flux discretization

flux = model_explicit_largedt.FluxDiscretization;

% Use explicit form of flow state

fb = ExplicitFlowStateBuilder();

fb.saturationCFL = 5;

fb.compositionCFL = inf; % Immiscible, saturation cfl is enough

flux = flux.setFlowStateBuilder(fb);

model_explicit_largedt.FluxDiscretization = flux;

model_explicit_largedt.stepFunctionIsLinear = true;

explicit_largedt = packSimulationProblem(state0, model_explicit_largedt, schedule, 'immiscible_time', 'Name', 'Explicit (CFL target 5)');

Simulate the problems¶

problems = {implicit, explicit, aim, explicit_largedt};

simulatePackedProblem(problems, 'continueOnError', false);

*******************************************************

* Case "immiscible_time" (Fully-Implicit) *

* Description: "Fully-Implicit_GenericBlackOilModel" *

*******************************************************

-> Complete output found, nothing to do here.

*************************************************

* Case "immiscible_time" (Explicit) *

...

Get output and plot the well results¶

There are oscillations in the well curves. Increasing the CFL limit beyond unity will eventually lead to oscillations.

[ws, states, reports, names, T] = getMultiplePackedSimulatorOutputs(problems);

Found complete data for immiscible_time (Fully-Implicit): 158 steps present

Found complete data for immiscible_time (Explicit): 158 steps present

Found complete data for immiscible_time (Adaptive-Implicit (AIM)): 158 steps present

Found complete data for immiscible_time (Explicit (CFL target 5)): 158 steps present

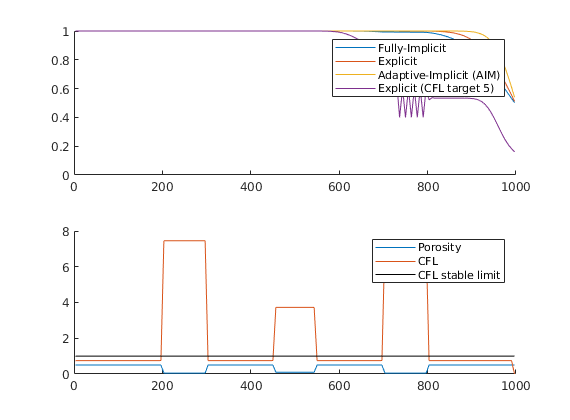

Plot the results¶

Note oscillations for CFL > 1.

figure(1);

for stepNo = 1:numel(schedule.step.val)

clf;

subplot(2, 1, 1);

hold on

for j = 1:numel(states)

plotCellData(G, states{j}{stepNo}.s(:, 1))

end

legend(names);

subplot(2, 1, 2); hold on;

plotCellData(G, rock.poro);

dt = schedule.step.val(stepNo);

state = states{1}{stepNo};

cfl = estimateSaturationCFL(model, state, dt);

plotCellData(G, cfl);

plotCellData(G, ones(G.cells.num, 1), 'Color', 'k');

legend('Porosity', 'CFL', 'CFL stable limit');

drawnow

end

Plot the fraction of cells which are implicit¶

imp_frac = cellfun(@(x) sum(x.implicit)/numel(x.implicit), states{3});

figure;

plot(100*imp_frac);

title('Number of implicit cells in AIM')

ylabel('Percentage of implicit cells')

xlabel('Step index')

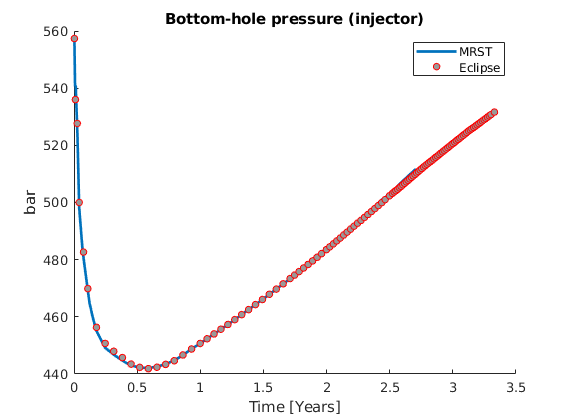

Plot the time-steps taken¶

The implicit solvers use the control steps while the explicit solver must solve many substeps.

igure; hold on

markers = {'o', '.', 'x', '.'};

for stepNo = 1:numel(reports)

dt = getReportMinisteps(reports{stepNo});

x = (1:numel(dt))/numel(dt);

plot(x, dt/day, markers{stepNo})

end

ylabel('Timestep length [day]')

xlabel('Fraction of total simulation time');

legend(names)

% <html>

% <p><font size="-1

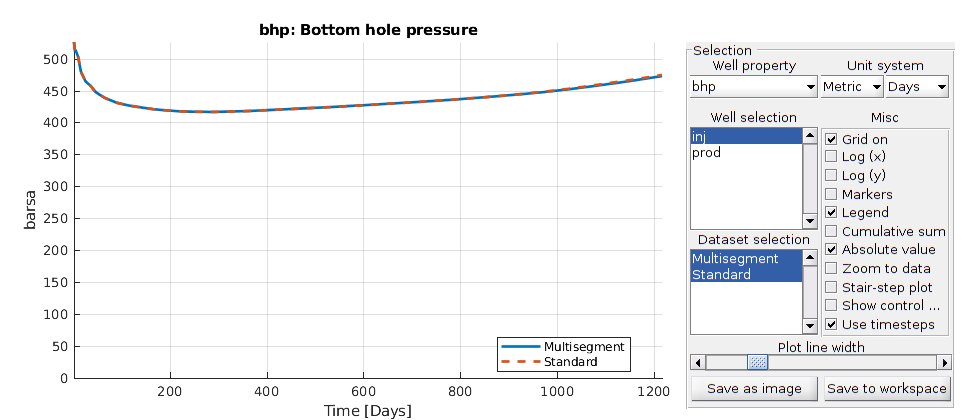

Multi-segment well example based on SPE 1 benchmark model¶

Generated from multisegmentWellExample.m

This example demonstrates the use of multisegment wells in MRST. The default wells in MRST assume flow in the well happens on a very short time-scale compared to the reservoir and can thus be accurately modelled by an instantaneous model. For some problems, however, more sophisticated well models may be required. The multisegment well class in MRST supports transient flow in the well. In addition, the class also allows for a more fine-grained representation of the well itself where the effect of valves and friction models can be included per segment.

% Load necessary modules

mrstModule add ad-blackoil ad-props deckformat ad-core mrst-gui

Set up model based on SPE 1¶

We use the SPE 1 example to get a simple black-oil case to modify. For more details on this model, see the the example blackoilTutorialSPE1.m.

[G, rock, fluid, deck, state] = setupSPE1();

[nx, ny] = deal(G.cartDims(1),G.cartDims(2));

model = ThreePhaseBlackOilModel(G, rock, fluid, 'inputdata', deck);

% Add extra output

model.extraStateOutput = true;

% Convert the deck schedule into a MRST schedule

schedule = convertDeckScheduleToMRST(model, deck);

No converter needed in section 'REGIONS'.

No converter needed in section 'SUMMARY'.

Adding 200 artificial cells at top/bottom

Processing regular i-faces

Found 550 new regular faces

Elapsed time is 0.008292 seconds.

...

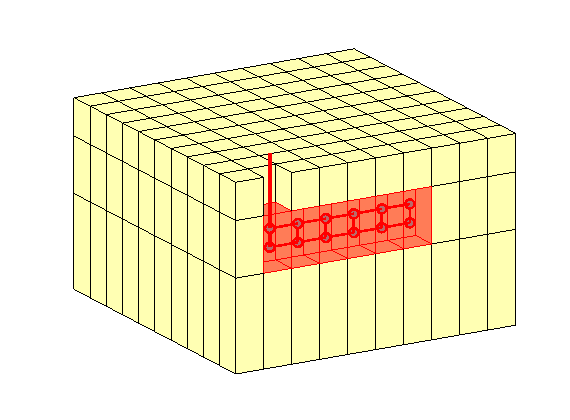

Construct multisegment well, and replace producer in original example¶

The well has 13 nodes. Nodes correspond to volumes in the well and are analogous to the grid cells used when the reservoir itself is discretized. The well is perforated in six grid blocks and we add nodes both for the wellbore and the reservoir contacts. By modelling the nodes in the reservoir contacts and the wellbore separately, we can introduce a valve between the reservoir and the wellbore. Nodes 1-7 represents the wellbore (frictional pressure drop) Well segments 2-8, 3-9, …, 7-13 will represent valves Only nodes 8-13 are connected to reservoir (grid-cells c1-c6)

% connection grid cells (along edge of second layer)

c = nx*ny + (2:7)';

% Make a conceptual illustration of the multisegment horizontal well

clf

flag=true(G.cells.num,1); flag([2; c])=false;

plotGrid(G,flag,'FaceColor',[1 1 .7]);

plotGrid(G,c,'FaceColor','r','FaceAlpha',.3,'EdgeColor','r','LineWidth',1);

x = G.cells.centroids(c,[1 1 1]); x(:,2) = NaN;

y = G.cells.centroids(c,[2 2 2]); y(:,2) = NaN;

z = G.cells.centroids(c,[3 3 3]); z(:,2) = NaN;

z(:,1) = z(:,1)+1.5; z(:,3) = z(:,3)-1.5;

hold on

plot3(x(1,[1 1]), y(1,[1 1]), z(1,1) - [0 15], '-r', 'LineWidth',3);

plot3(x, y, z,'-or','MarkerSize',7,'MarkerFaceColor',[.6 .6 .6],'LineWidth',2);

plot3(x(:,[1 3 2])',y(:,[1 3 2])',z(:,[1 3 2])','-r','LineWidth',2);

hold off, view(-30,25), axis tight off

First, initialize production well as “standard” well structure

prodS = addWell([], G, rock, c, 'name', 'prod', ...

'refDepth', G.cells.centroids(1,3), ...

'type', 'rate', 'val', -8e5*meter^3/day);

% Define additional properties needed for ms-well

% We have 12 node-to-node segments

topo = [1 2 3 4 5 6 2 3 4 5 6 7

2 3 4 5 6 7 8 9 10 11 12 13]';

% | tubing | valves |

% Create sparse cell-to-node mapping

cell2node = sparse((8:13)', (1:6)', 1, 13, 6);

% Segment lengths/diameters and node depths/volumes

lengths = [300*ones(6,1); nan(6,1)];

diam = [.1*ones(6,1); nan(6,1)];

depths = G.cells.centroids(c([1 1:end 1:end]), 3);

vols = ones(13,1);

% Convert to ms-well

prodMS = convert2MSWell(prodS, 'cell2node', cell2node, 'topo', topo, 'G', G, 'vol', vols, ...

'nodeDepth', depths, 'segLength', lengths, 'segDiam', diam);

% Finally, we set flow model for each segment:

% segments 1-6: wellbore friction model

% segments 7-12: nozzle valve model

% The valves have 30 openings per connection

[wbix, vix] = deal(1:6, 7:12);

[roughness, nozzleD, discharge, nValves] = deal(1e-4, .0025, .7, 30);

% Set up flow model as a function of velocity, density and viscosity

prodMS.segments.flowModel = @(v, rho, mu)...

[wellBoreFriction(v(wbix), rho(wbix), mu(wbix), prodMS.segments.diam(wbix), ...

prodMS.segments.length(wbix), roughness, 'massRate'); ...

nozzleValve(v(vix)/nValves, rho(vix), nozzleD, discharge, 'massRate')];

% In addition, we define a standard gas injector. Different well types can

% easily be combined in MRST, each with their own models for pressure drop

% and solution variables.

inj = addWell([], G, rock, 100, 'name', 'inj', 'type', 'rate', 'Comp_i', [0 0 1], ...

'val', 2.5e6*meter^3/day,'refDepth', G.cells.centroids(1,3));

Run schedule with simple wells¶

We first simulate a baseline where the producer is treated as a simple well with instantaneous flow and one node per well-reservoir contact.

W_simple = [inj; prodS];

schedule.control.W = W_simple;

[wellSolsSimple, statesSimple] = simulateScheduleAD(state, model, schedule);

*****************************************************************

********** Starting simulation: 120 steps, 1216 days *********

*****************************************************************

Preparing model for simulation...

Model ready for simulation...

Preparing schedule for simulation...

Schedule ready for simulation...

Validating initial state...

...

Set up well models¶

We combine the simple and multisegment well together

W = combineMSwithRegularWells(inj, prodMS);

schedule.control.W = W;

% Initialize the facility model. This is normally done automatically by the

% simulator, but we do it explicitly on the outside to view the output

% classes. This approach is practical if per-well adjustments to e.g.

% tolerances are desired.

% First, validate the model to set up a FacilityModel

model = model.validateModel();

% Then apply the new wells to the FacilityModel

model.FacilityModel = model.FacilityModel.setupWells(W);

% View the simple injector

disp(model.FacilityModel.WellModels{1})

% View the multisegment producer

disp(model.FacilityModel.WellModels{2})

SimpleWell with properties:

W: [1×1 struct]

allowCrossflow: 1

allowSignChange: 0

allowControlSwitching: 1

dpMaxRel: Inf

dpMaxAbs: Inf

...

Run the same simulation with multisegment wells¶

Note that if verbose output is enabled, the convergence reports will include additional fields corresponding to the well itself.

[wellSols, states, report] = simulateScheduleAD(state, model, schedule);

*****************************************************************

********** Starting simulation: 120 steps, 1216 days *********

*****************************************************************

Preparing model for simulation...

Model ready for simulation...

Preparing schedule for simulation...

Schedule ready for simulation...

Validating initial state...

...

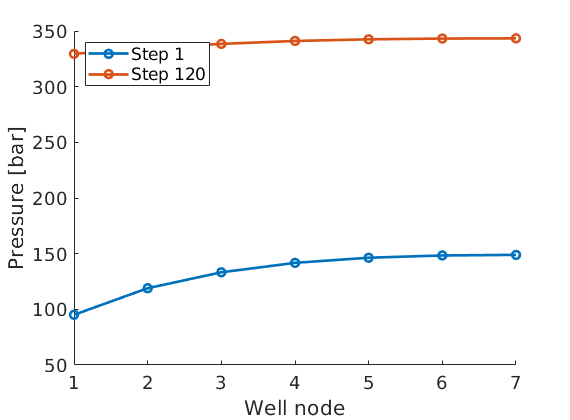

Plot the well-bore pressure in the multisegment well¶

Plot pressure along wellbore for step 1 and step 120 (final step)

figure, hold all

for k = [1 120]

plot([wellSols{k}(2).bhp; wellSols{k}(2).nodePressure(1:6)]/barsa, ...

'-o', 'LineWidth', 2);

end

legend('Step 1', 'Step 120', 'Location', 'northwest')

set(gca, 'Fontsize', 14), xlabel('Well node'), ylabel('Pressure [bar]')

Launch interactive plotting¶

We can compare the two different well models interactively and observe the difference between the two modelling approaches.

plotWellSols({wellSols, wellSolsSimple}, report.ReservoirTime, ...

'datasetnames', {'Multisegment', 'Standard'});

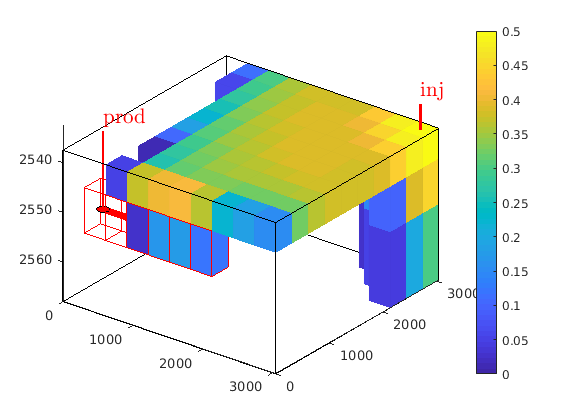

Show the advancing displacement front¶

mrstModule add coarsegrid

pg = generateCoarseGrid(G,ones(G.cells.num,1));

figure, h = [];

plotGrid(pg,'FaceColor','none');

plotGrid(G,c,'FaceColor','none','EdgeColor','r');

plotWell(G,[inj; prodS]);

caxis([0 .5]); view(37.5,34); caxis([0 .5]); axis tight; colorbar, drawnow;

for i=1:numel(states)

sg = states{i}.s(:,3); inx = sg>1e-5;

if sum(inx)>0

delete(h)

h=plotCellData(G,sg,sg>1e-4,'EdgeAlpha',.01);

colorbar

drawnow;

end

end

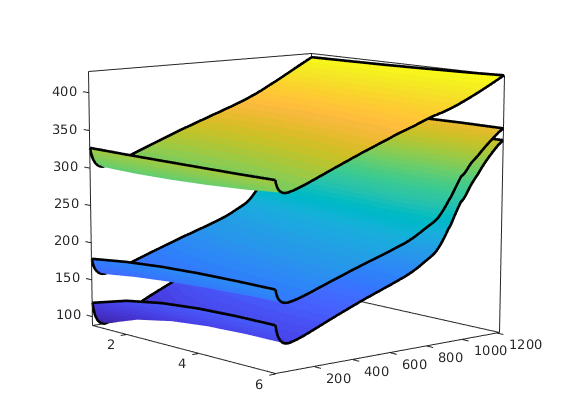

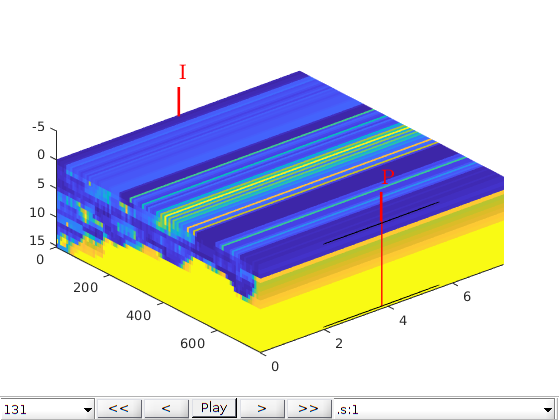

Visualize drawdown in well as function of time¶

We extract the pressure in all the nodes and visualize this, together with the pressure in the completed reservoir cells as function of time

[xx,tt]=meshgrid(1:6,report.ReservoirTime/day);

pr = cellfun(@(x) x.pressure(c)', states, 'UniformOutput',false);

pa = cellfun(@(x) x(2).nodePressure(7:12)', wellSols, 'UniformOutput',false);

pw = cellfun(@(x) x(2).nodePressure(1:6)', wellSols, 'UniformOutput',false);

figure

hold on

surfWithOutline(xx, tt, vertcat(pr{:})/barsa);

surfWithOutline(xx, tt, vertcat(pa{:})/barsa);

surfWithOutline(xx, tt, vertcat(pw{:})/barsa);

hold off, box on, axis tight

view(50,10), shading interp

set(gca,'Projection','Perspective');

akse = axis();

cax = caxis();

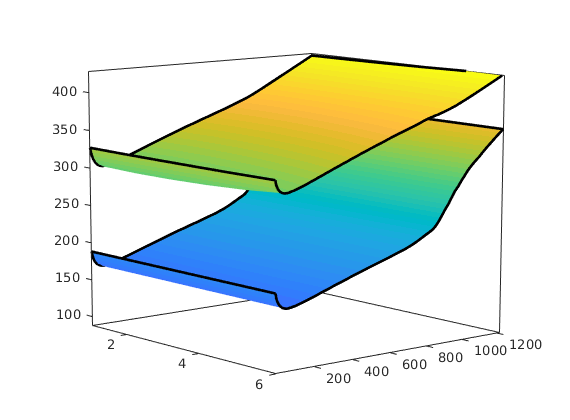

r = cellfun(@(x) x.pressure(c)', statesSimple, 'UniformOutput',false);

pw = cellfun(@(x) x(2).bhp + x(2).cdp', wellSolsSimple, 'UniformOutput',false);

figure

hold on

surfWithOutline(xx, tt, vertcat(pr{:})/barsa);

surfWithOutline(xx, tt, vertcat(pw{:})/barsa);

hold off, box on, axis tight, axis(akse), caxis(cax)

view(50,10), shading interp

set(gca,'Projection','Perspective');

% <html>

% <p><font size="-1

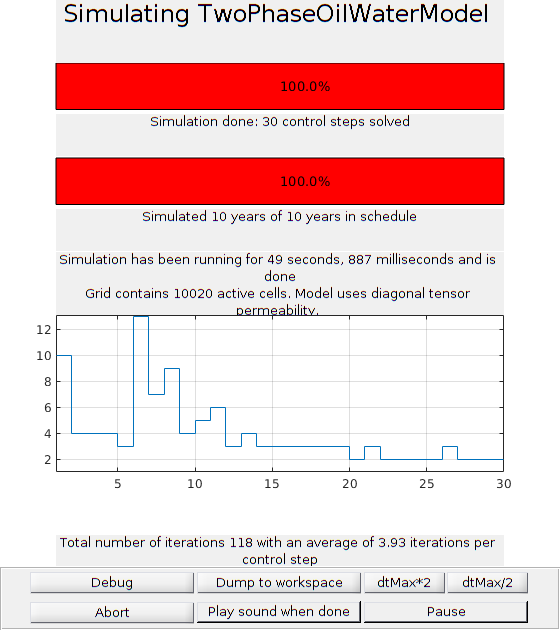

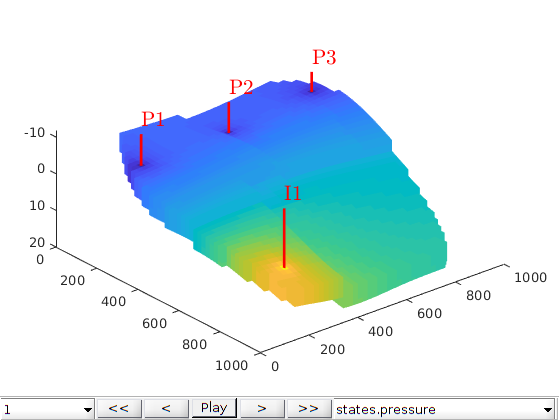

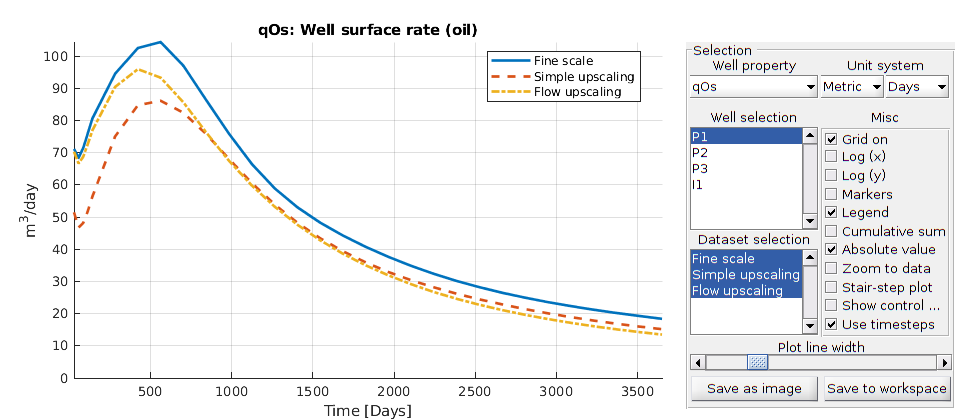

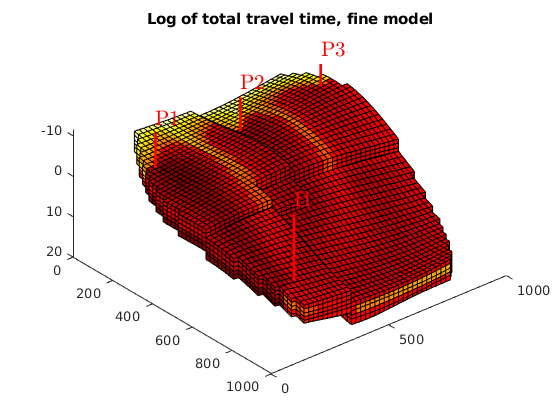

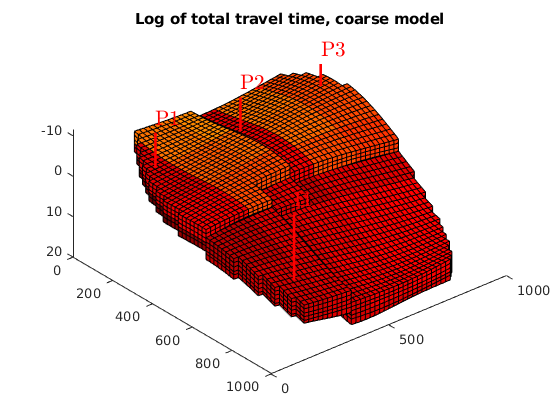

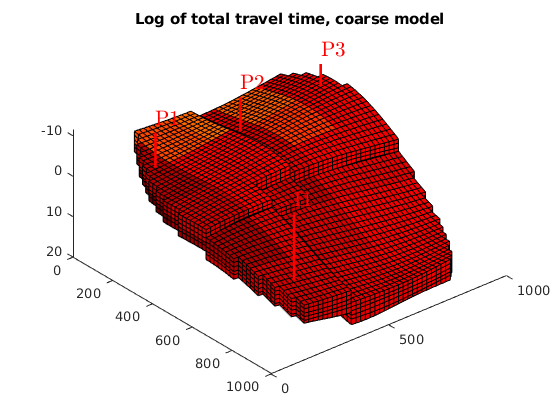

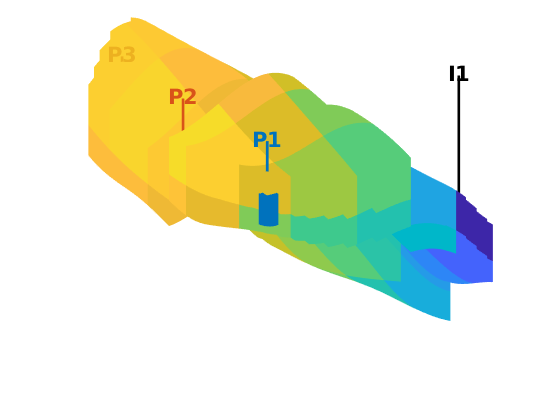

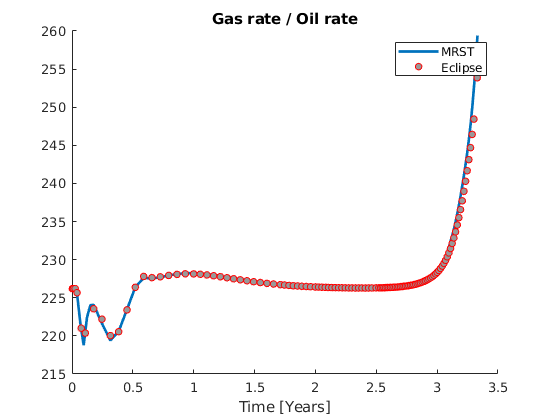

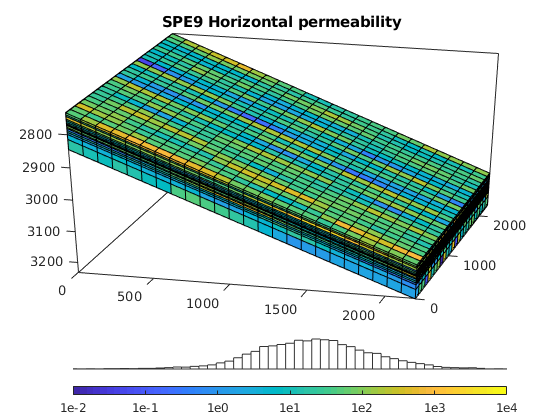

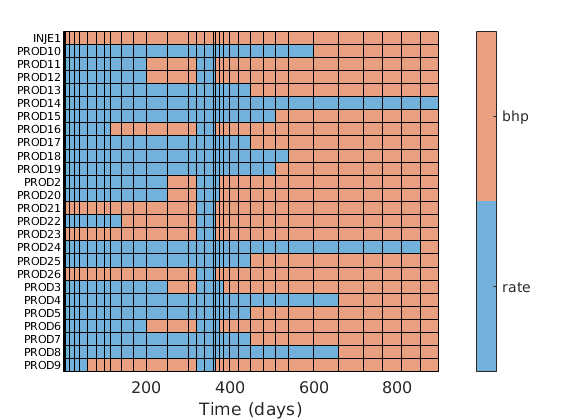

Workflow example for MRST-AD¶

Generated from simulatorWorkflowExample.m

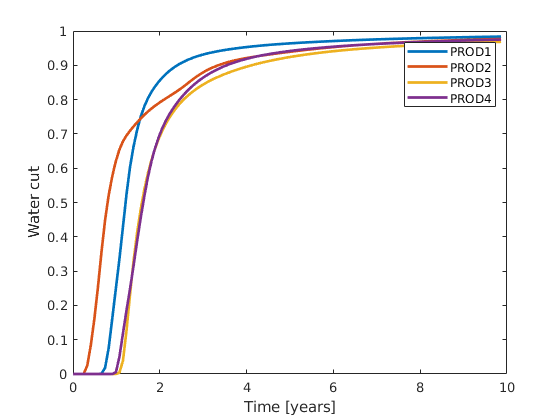

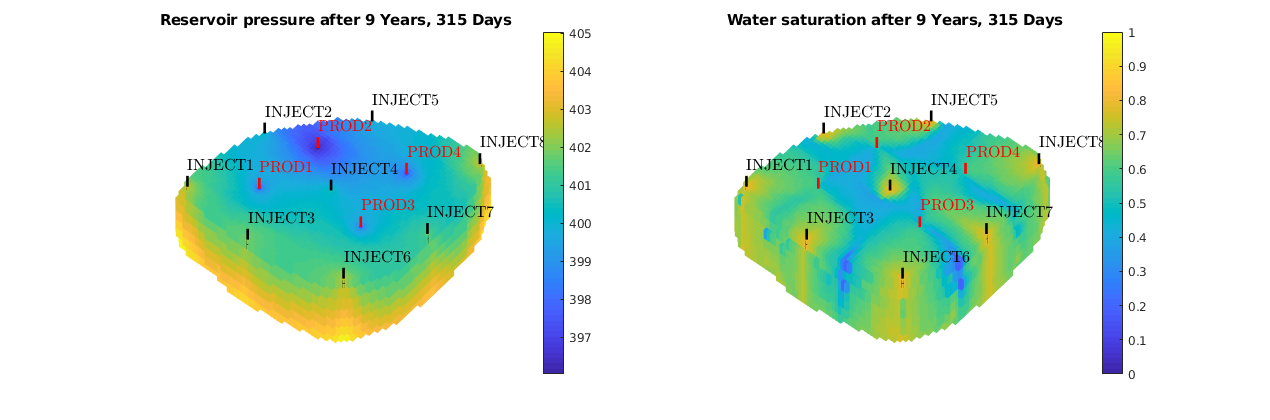

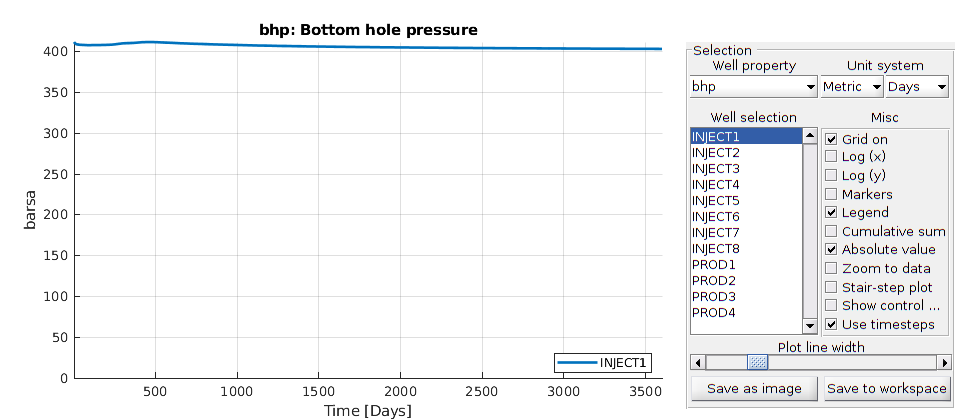

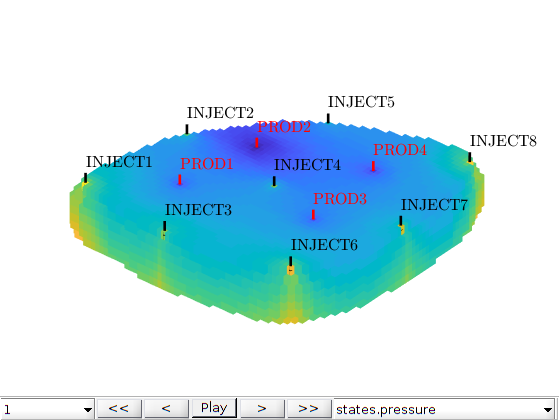

This example aims to show the complete workflow for creating, running and analyzing a simulation model. Unlike the other examples, we will create all features of the model manually to get a self-contained script without any input files required. The model we setup is a slightly compressible two-phase oil/water model with multiple wells. The reservoir has a layered strategraphy and contains four intersecting faults. Note that this example features a simple conceptual model designed to show the workflow rather than a problem representing a realistic scenario in terms of well locations and fluid physics.

mrstModule add ad-core ad-blackoil ad-props mrst-gui

close all;

Reservoir geometry and petrophysical properties¶

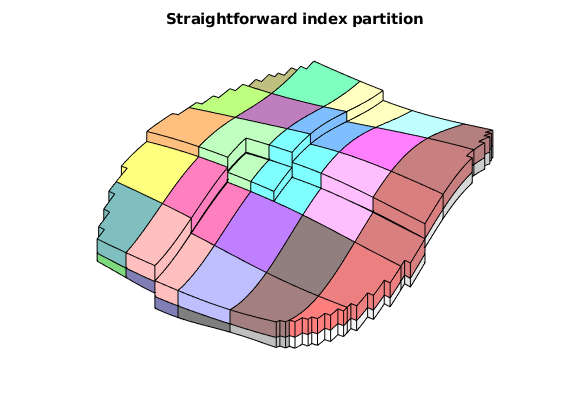

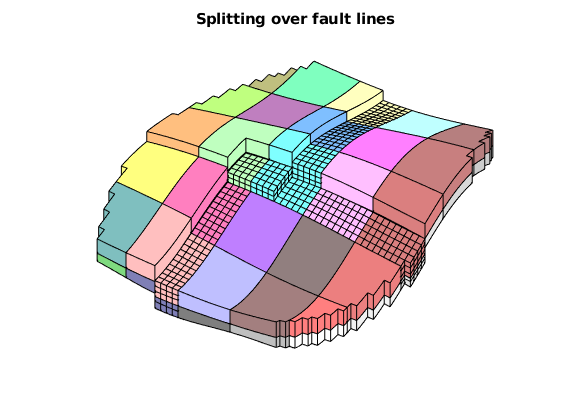

We begin by setting up the grid and rock structures. The grid is created by “makeModel3”, which creates a structured model with intersecting faults. We assume a layered permeability structure with 300, 100, and 500 md in the lower, middle, and top layers. respectively.

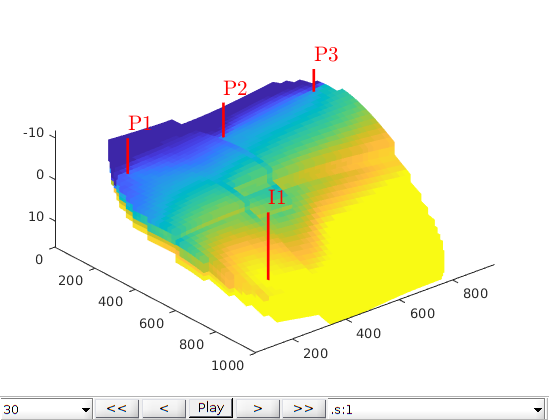

% Define grid

grdecl = makeModel3([50, 50, 5], [1000, 1000, 5]*meter);

G = processGRDECL(grdecl);

G = computeGeometry(G);

% Set up permeability based on K-indices

[I, J, K] = gridLogicalIndices(G);

top = K < G.cartDims(3)/3;

lower = K > 2*G.cartDims(3)/3;

middle = ~(lower | top);

px = ones(G.cells.num, 1);

px(lower) = 300*milli*darcy;

px(middle) = 100*milli*darcy;

px(top) = 500*milli*darcy;

% Introduce anisotropy by setting K_x = 10*K_z.

perm = [px, px, 0.1*px];

rock = makeRock(G, perm, 0.3);

% Plot horizontal permeability and wells

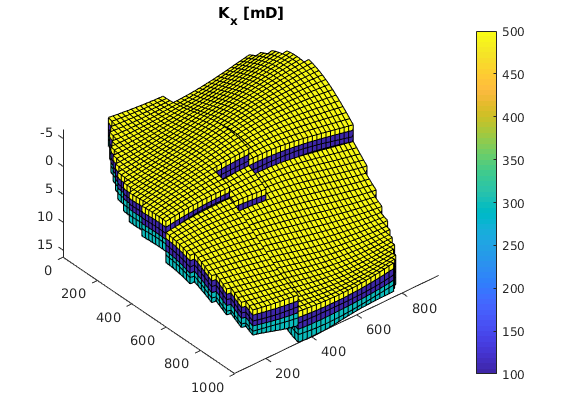

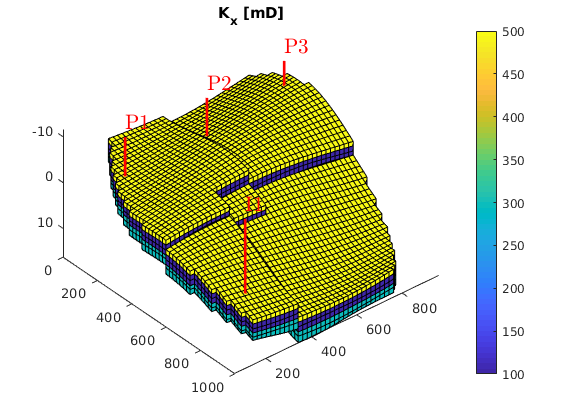

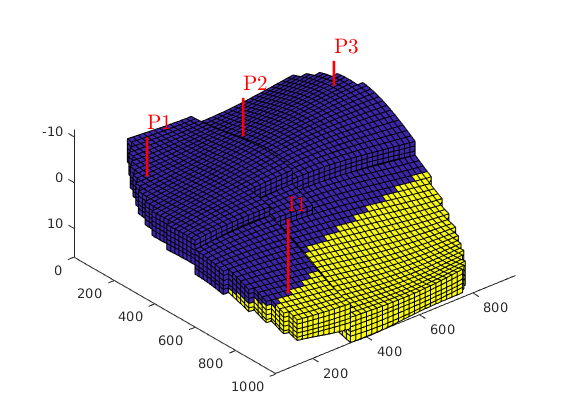

figure(1); clf

plotCellData(G, rock.perm(:, 1)/(milli*darcy))

view(50, 50), axis tight

colorbar

title('K_x [mD]')

Adding 5000 artificial cells at top/bottom

Processing regular i-faces

Found 14964 new regular faces

Elapsed time is 0.012135 seconds.

Processing i-faces on faults

Found 58 faulted stacks

...

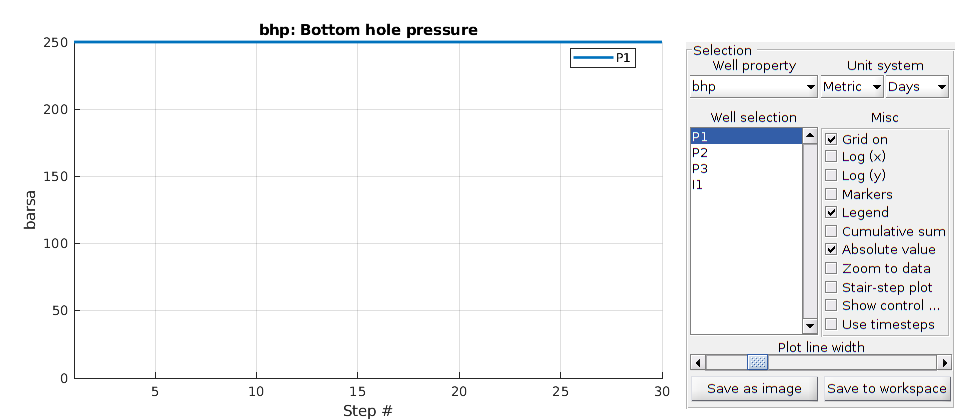

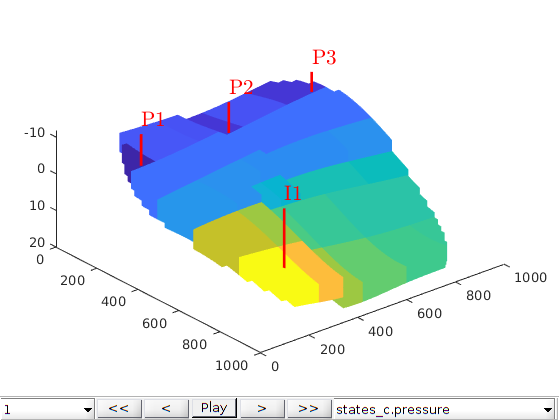

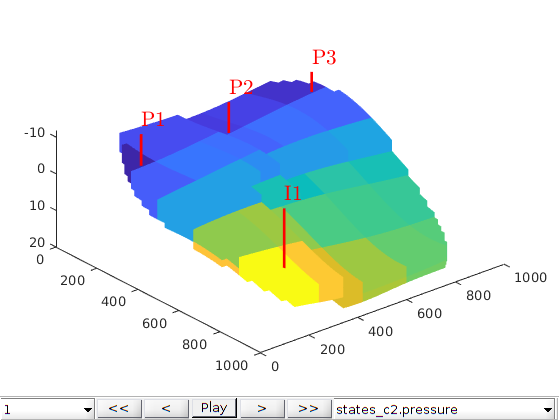

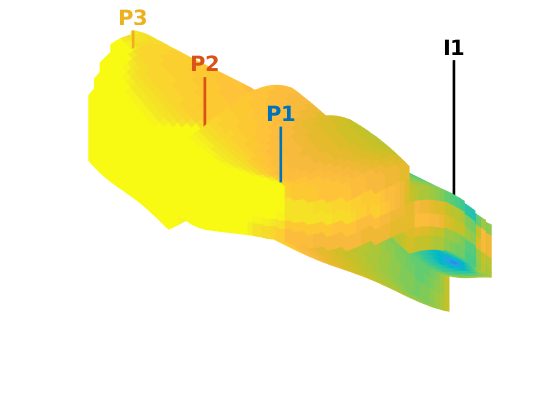

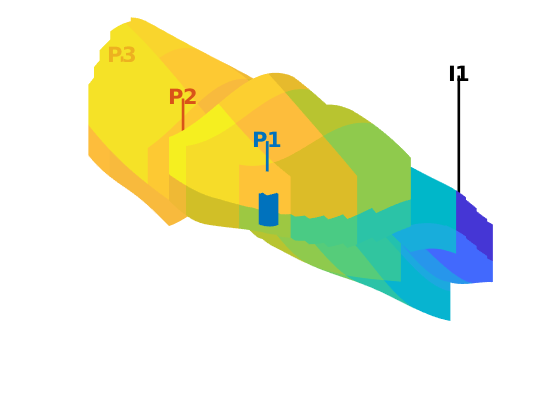

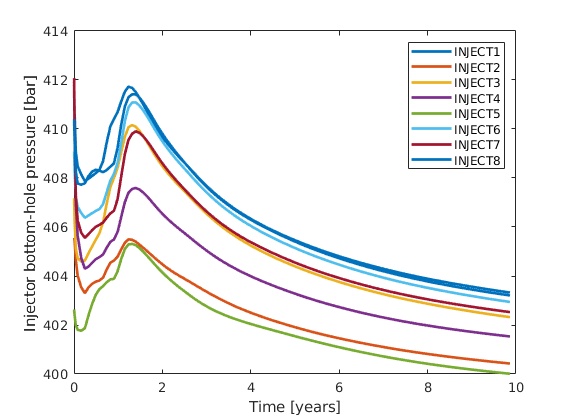

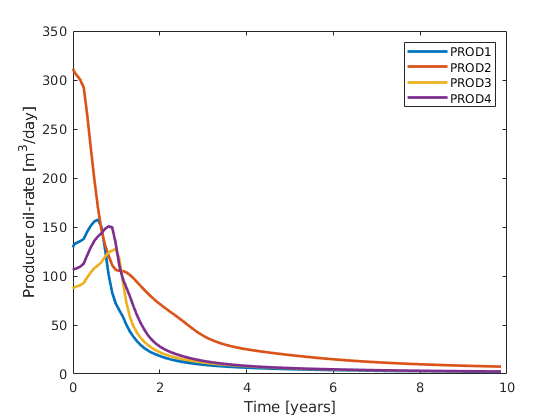

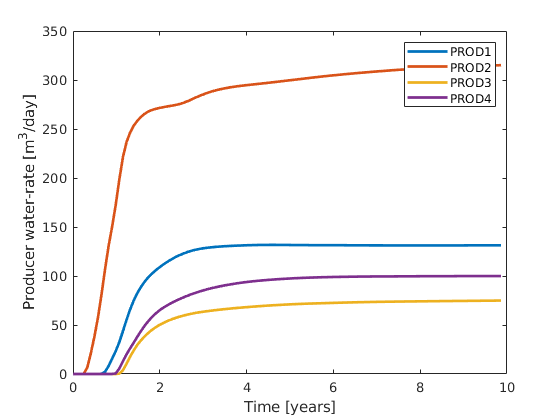

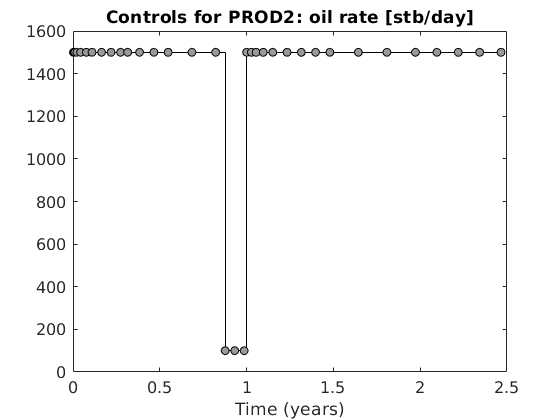

Define wells and simulation schedule¶

Hydrocarbon is recovered from producers, operating at fixed bottom-hole pressure and perforated throughout all layers of the model. The producers are supported by a single water injector set to inject one pore volume over 10 years (the total simulation length). We also set up a schedule consisting of 5 small control steps initially, followed by 25 larger steps. We keep the well controls fixed throughout the simulation.

simTime = 10*year;

nstep = 25;

refine = 5;

% Producers

pv = poreVolume(G, rock);

injRate = 1*sum(pv)/simTime;

offset = 10;

W = verticalWell([], G, rock, offset, offset, [],...

'Name', 'P1', 'comp_i', [1 0], 'Val', 250*barsa, 'Type', 'bhp', 'refDepth', -8);

W = verticalWell(W, G, rock, offset, floor(G.cartDims(1)/2)+3, [],...

'Name', 'P2', 'comp_i', [1 0], 'Val', 250*barsa, 'Type', 'bhp', 'refDepth', -8);

W = verticalWell(W, G, rock, offset, G.cartDims(2) - offset/2, [], ...

'Name', 'P3', 'comp_i', [1 0], 'Val', 250*barsa, 'Type', 'bhp', 'refDepth', -8);

% Injectors

W = verticalWell(W, G, rock, G.cartDims(1)-5, offset, 1,...

'Name', 'I1', 'comp_i', [1 0], 'Val', injRate, 'Type', 'rate', 'refDepth', -8);

% Compute the timesteps

startSteps = repmat((simTime/(nstep + 1))/refine, refine, 1);

restSteps = repmat(simTime/(nstep + 1), nstep, 1);

timesteps = [startSteps; restSteps];

% Set up the schedule containing both the wells and the timesteps

schedule = simpleSchedule(timesteps, 'W', W);

% Plot the wells

plotWell(G, W)

axis tight

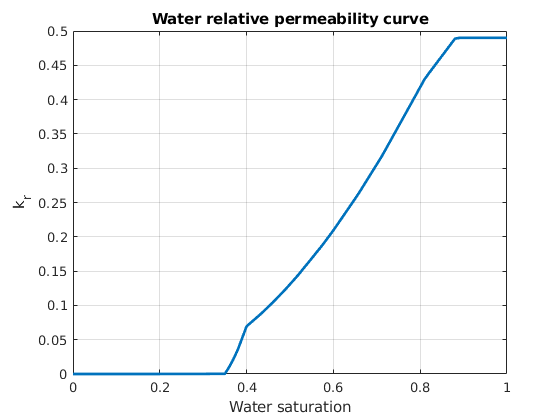

Set up simulation model¶

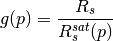

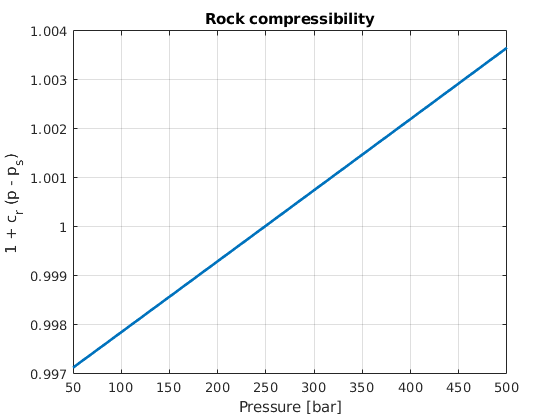

We set up a two-phase oil-water simulation model based on automatic differentiation. The resulting object is a special case of a general three-phase model and to instantiate it, we start by constructing a two-phase fluid structure with properties given for oil and water. Water is assumed to be incompressible, whereas oil has constant compressibility, giving a reciprocal formation volume factor of the form,

. To define this relation, we set the ‘bo’ field of the fluid structure to be an anonymous function that calls the builtin ‘exp’ function with appropriate arguments. Since the fluid model is a struct containing function handles, it is simple to modify the fluid to use alternate functions. We then pass the fundamental structures (grid, rock and fluid) onto the two-phase oil/water model constructor.

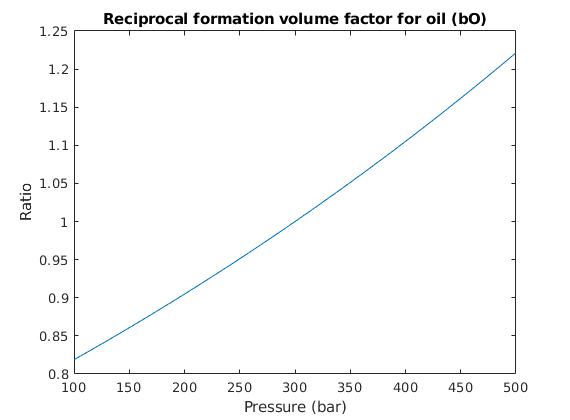

% Three-phase template model

fluid = initSimpleADIFluid('mu', [1, 5]*centi*poise, ...

'rho', [1000, 700]*kilogram/meter^3, ...

'n', [2, 2], ...

'cR', 1e-8/barsa, ...

'phases', 'wo');

% Constant oil compressibility

c = 0.001/barsa;

p_ref = 300*barsa;

fluid.bO = @(p, varargin) exp((p - p_ref)*c);

clf

p0 = (100:10:500)*barsa;

plot(p0/barsa, fluid.bO(p0))

xlabel('Pressure (bar)')

ylabel('Ratio')

title('Reciprocal formation volume factor for oil (bO)')

% Construct reservoir model

gravity reset on

model = TwoPhaseOilWaterModel(G, rock, fluid);

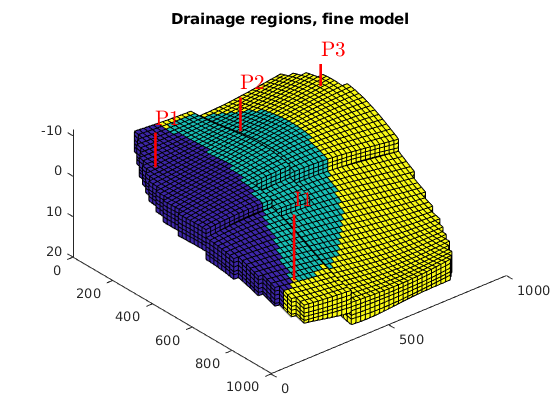

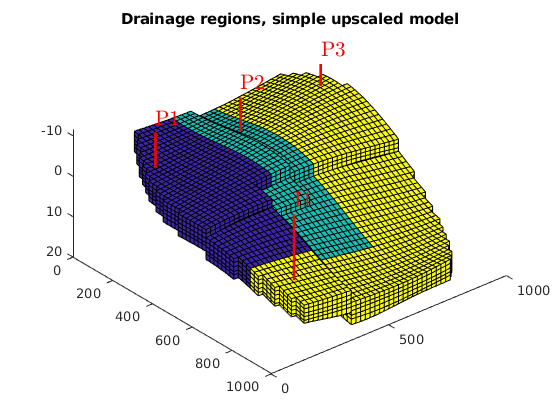

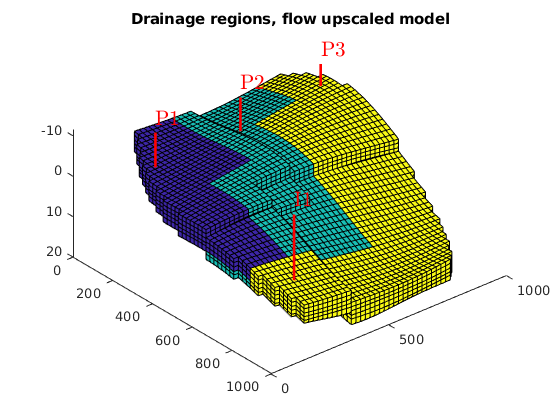

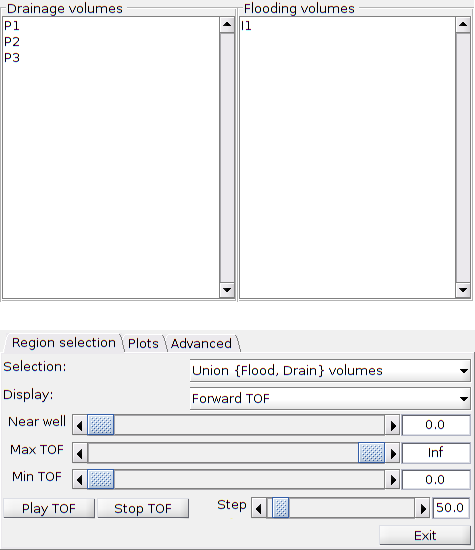

Define initial state¶