Objectives

The main objective of the project is to develop a first-of-its-kind hybrid structured adsorbent, with tailor-designed shapes and surface groups, fabricated by high-resolution additive manufacturing for production of chromatographic devices to purify complex biopharmaceutical compounds and bring an accelerated time-to-market of novel materials and process intensification to the production of vaccines and gene therapy.

The principal target of the project is to increase the efficiency of the virus purification process.

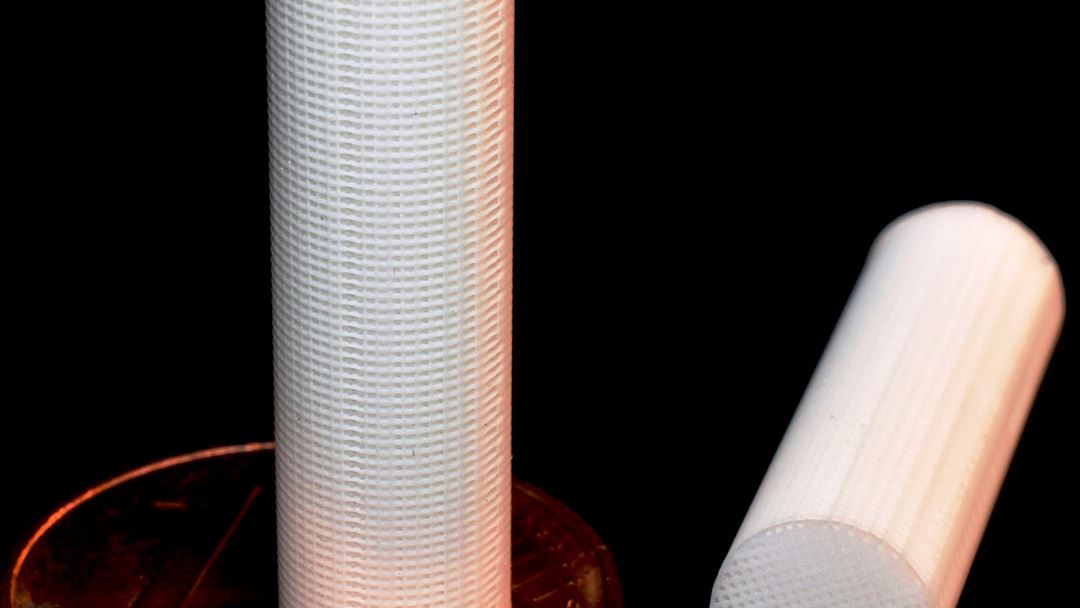

Additive manufacturing (AM) is a method to generate objects from digital files. The advantage of customization achievable by AM is such that it allows full control of the geometry to be produced. Materials play a key role in all AM processes and different 3D printing technologies have very different resolutions and produce final results. The development of new materials for AM is indeed a main target in Europe.

The utilization of AM in the chemical and pharmaceutical industries is relatively new and has enormous prospects to move these industries to a new paradigm in production technologies with increased efficiency and reduced utilization of resources.In chromatography, polymer AM was used to demonstrate that control of shape can be useful to achieve better operations.

The novel materials will be used to develop continuous processes for purification of biopharmaceuticals, namely Simulated Moving Bed (SMB). The SMB achieves high column throughput, low product dilution, and low solvent consumption.