Decision support tools

Models for decision support tools have been developed for the installation phase and the operational phase of offshore wind farms. The main focus has been on decisions on a strategic level, and in particular the fleet size and mix decisions: Which vessels and corresponding infrastructure are the most promising ones for a given offshore wind farm?

Strategic decision support tools

INSTALLATION PHASE

COSMO

For the bidding phase of an offshore wind park, a computer tool for optimisation and simulation of marine operations (COSMO) has been developed in close cooperation with Equinor. The tool is currently being tested and validated and will be further improved through the FME NorthWind research centre.

LIVO

In the EU FP7 project LEANWIND a decision support tool has been developed to determine optimal vessel fleet: LIVO - LEANWIND Installation Vessel Optimizer.

The tool focuses on determining optimal vessel fleet and the installation schedule. Objectives can be selected to both minimizing total cost and minimizing total installation time.

- Excel based input/output scheme

- Considers weather conditions: Wind and wave

- Deterministic mathematical optimization model implemented in FICO® Xpress Optimization Suite

- Requires a license for FICO® Xpress Optimization Suite

OPERATION & MAINTENANCE PHASE

Several models have been developed for the vessel fleet size and mix problem for maintenance operations at offshore wind farms. Three of them have been developed into decision support tools. These all build on the same mathematical model formulation, but there exists three different versions based on the solution methodology. All three versions operate with an Excel based input/output scheme.

Vessel fleet optimization model – deterministic

- All input parameters are considered known

- Deterministic mathematical optimization model implemented in FICO® Xpress Optimization Suite

- Run by an application coded in C#

- Requires a license for FICO® Xpress Optimization Suite

Vessel fleet optimization model – stochastic

- Weather conditions and corrective maintenance tasks are stochastic

- Stochastic mathematical optimization model implemented in FICO® Xpress Optimization Suite

- Run by an application coded in C#

- Requires a license for FICO® Xpress Optimization Suite

HOWLOG – Heuristic solver for Offshore Wind o&m LOGistics resource management

- Weather conditions and corrective maintenance tasks are stochastic

- Heuristic solution methodology – cannot guarantee the "optimal" solution

- Run by a Java application

- Does not require any external software license

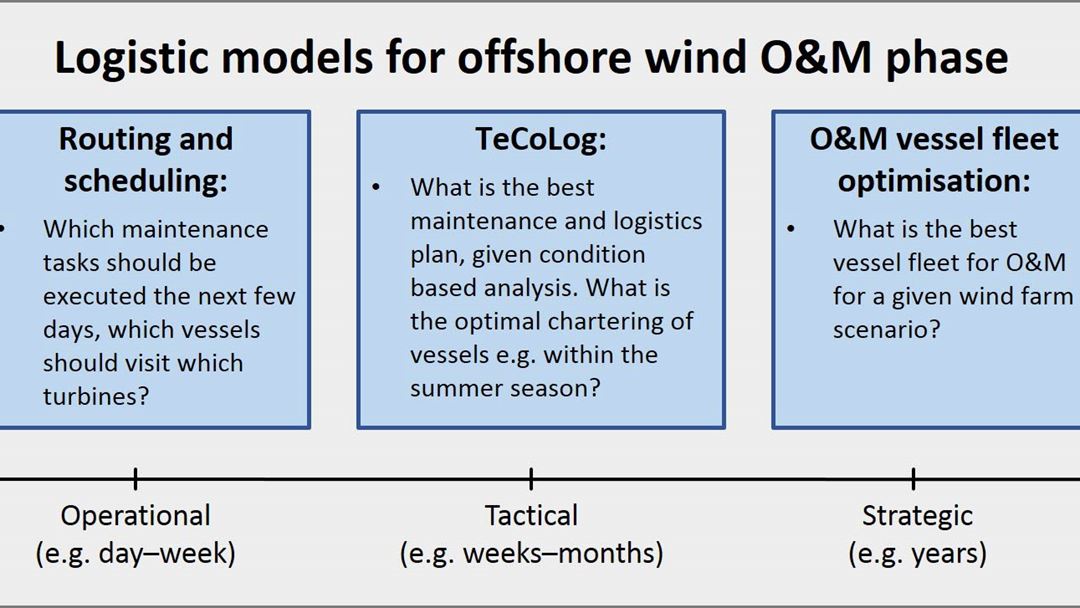

Tactical decision support for the Operation & Maintenance Phase

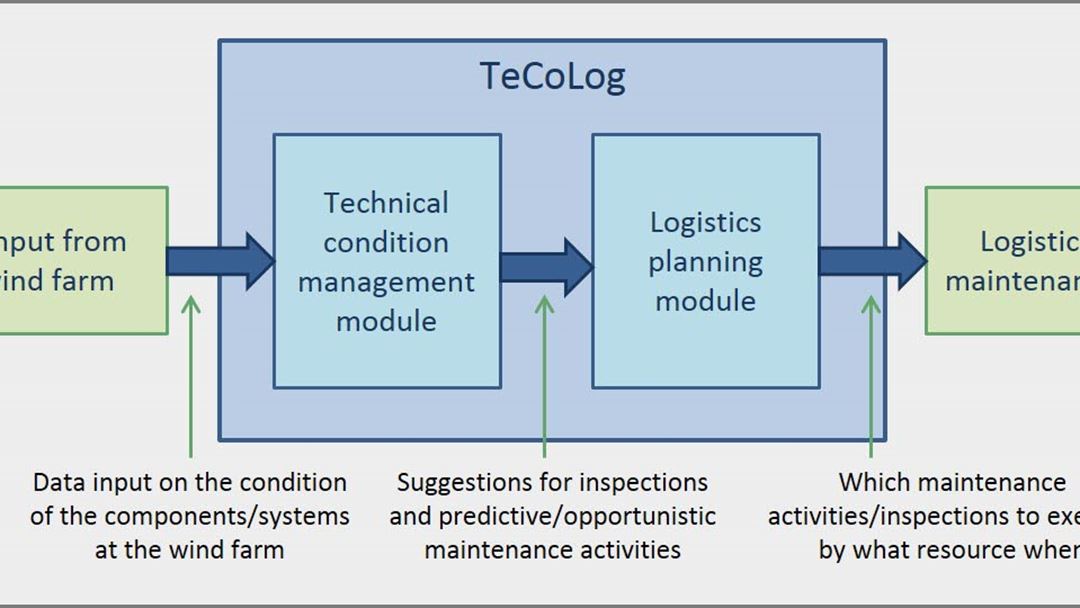

In the LEANWIND project, SINTEF Ocean (MARINTEK) has been looking at combining condition based monitoring with resource management and scheduling of maintenance tasks. This has resulted in the conceptual TeCoLog – Technical Condition based Logistic Planner – a decision support system that combines an existing decision support system for technical condition monitoring – TeCoMan (Technical Condition Manager) with a tactical version of the vessel fleet optimization model for O&M.

TeCoLog represent a decision support system for foresighted intelligent planning of O&M tasks, and can reduce LCOE (Life Cycle Cost of Energy) by optimized scheduling of O&M tasks and selection of resource requirements for execution of O&M tasks.

The technical condition module in TeCoLog contains an adaption of TeCoMan to offshore wind farms. It consists of on-line monitoring and analysis of technical conditions from different wind turbine components. This information will be input to the logistic module, that will take potential maintenance tasks (preventive/corrective/condition based) and available resources as input, and determine an optimal maintenance schedule consisting of which maintenance tasks to execute when with which resources (vessels/helicopters/technicians), and which vessels to charter-in/-out on a short-term basis.

OPERATIONAL DECISION SUPPORT FOR THE OPERATION & MAINTENANCE PHASE

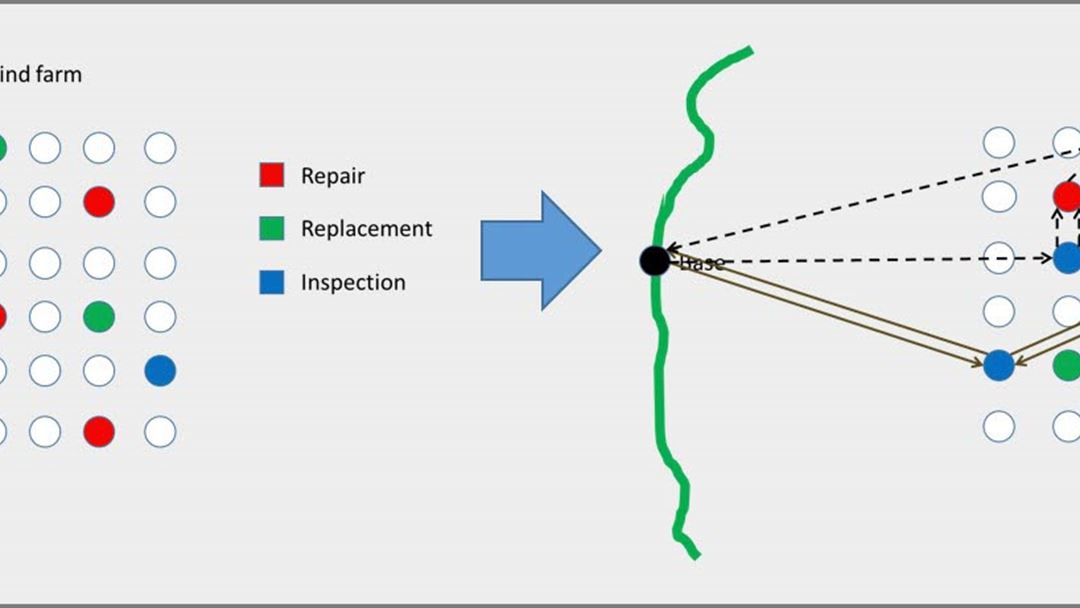

Within the NOWITECH Research Centre, SINTEF Ocean (MARINTEK) has been involved in developing routing and scheduling models for maintenance tasks at offshore wind farms. This is an operational problem considering which maintenance tasks that should be executed the following day, or following few days.

The routing and scheduling models consider the following aspects:

- Optimised routing of vessels with respect to transportation costs (minimise fuel costs), downtime costs and prioritarisation of maintenance tasks

- Optimised number of technicians: How many technicians to transport on each vessels, how many to be dropped-off and picked-up at turbines when

- Which maintenance tasks should be executed when: Supported by which vessels, and executed by which technicians