Digital and Physical Technologies

Integrating and Demonstrating Digital and Physical Technologies to Enable make on demand for FMCG

Introduction

DIY4U aims to develop and promote adoption of collaborative small-scale production approaches and product personalisation in the FMCG sector. The current landscape of relevant digital infrastructure, manufacturing facilities and business models limits FMCG product personalisation/customisation. DIY4U aims to address the blockers of product customisation and small-scale manufacturing by developing an open innovation Digital B2B/B2C Platform and digitally enabled small-scale manufacturing machines (Fablabs) and deliver an end to end digitally supported supply chain. By enabling personalisation of FMCG, DIY4U aims to enhance the innovation capacity and competitiveness of the EU FMCG sector via decentralized customer-centric production. The Fablabs (developed and hosted at manufacturing demonstration facilities) will be used for on-demand production of new personalised or customised soft matter FMCG designed using the DIY4U digital platform.

Digital Platform

Through the platform the user can design and order their personalised FMCG and receive information on the sustainability (carbon footprint) of their choices. Transparently to the user, machine learning algorithms convert the customer choices into an optimised formulation and this is modelled to optimise the production process in the fablab. The DIY4U Digital Platform is built using a decentralized micro-service-oriented framework and incorporates basic e-commerce functions, customized processes, dashboards and specific actions for all user types.

The Digital Platform is designed as a decentralized system, with a blockchain based infrastructure to deal with the decision-making process, information storage, file storage, traceability, protected intellectual property. Each of the components is served by a dedicated network of nodes that are controlled and managed by the DIY4U consortium etc. The network of Fablabs is connected to the platform through this infrastructure. Additionally there are a number of extensions to the platform - simulations, carbon footprint calculator, price calculation, analytics, connectors for external service providers, etc. Due to the modular design of the platform, further extensions can be added, e.g. through the Open Innovation Projects.

Fablabs Overview

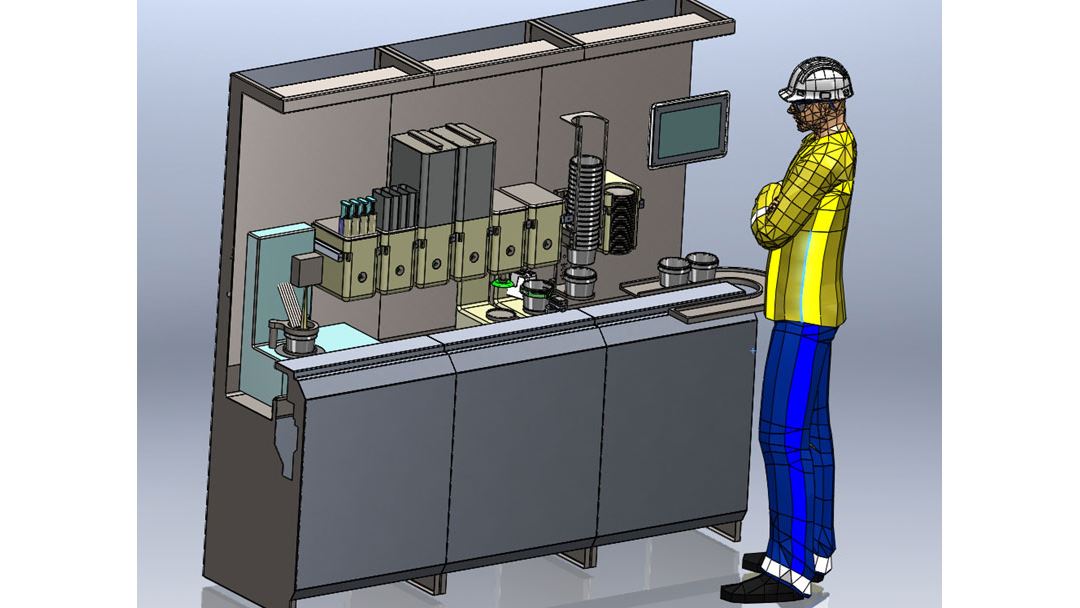

Two Fablabs (digitally enabled small-scale manufacturing machines) are being designed and built as part of the DIY4U project. These machines will take chemical feedstocks and process them into customised laundry detergents under the direction of the DIY4U Digital Platform, based on a user’s customisation requests into the Platform. The Fablabs will take typically five feedstocks and use them to manufacture a customised detergent at a 0.5 – 1 Litre scale. SINTEF and CPI will host the developed Fablabs in their innovation laboratories and act as open access Manufacturing Demonstration Facilities (MDF), offering Fablab manufacturing services to individuals and companies (especially SMEs) using the DIY4U Digital Platform to design new customised/personalised products. There will be a Fablab for producing powder laundry detergents to be based at SINTEF and a Fablab for liquid laundry detergents based at CPI. The MDFs will also offer training to companies and individuals looking to adopt the new DIY formulation design and manufacturing approach.

The Fablabs will accept the designed recipe from the Digital Platform, dose in the required powders / liquids, mix components in the appropriate conditions, check composition using specialised measurement techniques (Process Analytic Technology, PAT) and dispense into a final package for the consumer. This package will be labelled as required. Production data as required will be fed back to the Digital Platform.

Fablab manufacturing will be in accordance with the relevant EC machinery and EMC directives, and operated according to EC and national safety, health and environmental (SHE) requirements. The physical design is highly modular and extendable as described further in the next section. The Fablabs shall have a visual operator interface, informing the operator of its status, required actions and maintenance plan. The operator shall be able to perform maintenance, add or change feedstock, add or remove unit operations and confirm these actions through the operator interface. (For the duration of the project it is expected that the Fablabs will be operated by trained operators, not end-users / consumers). Each Fablab will connect to the DIY4U Digital Platform, which will be the main user / consumer-facing interface.

Open Innovation with DIY4U

During the project there are two fully-funded Open Innovation Competitions (OICs) to encourage SMEs to engage with the DIY4U concept. The first OIC has just completed with 4 SMEs being granted 50kEU each to develop 4 new software modules for the Digital Platform in the areas of (1) Sales Virtual Assistant, (2) Decentralised Payments, (3) Supply Chain Planning and (4) Performance Monitoring. A second OIC will be launched later this year (and extend into 2022) with a focus on using the DIY4U approach (digital platform and fablabs) for development of new customised FMCGs and new business offerings relating to the DIY4U approach. In addition to the OICs, in the second half of 2022 we hope to offer self-funded access to entrepreneurs, companies and organisations to produce formulations with DIY4U using the digital platform and fablab.

Summary

DIY4U will provide industrially relevant demonstration of physical and digital technologies and a disruptive business model for producing and selling FMCG, through development of a Digital Platform for customers to design and purchase products and Fablabs to locally produce the product. This will showcase a more sustainable DIY / “designed for me” approach for the FMCG sector.