|

Minimizing leakage and excess pressure buildup

The storage capacity of the Bjarmeland formation is assessed by obtaining optimized injection strategies while penalizing leakage and pressure buildup. This example demonstrates that pressure is an important aspect when designing injection strategies. Managing pressure buildup in the formation can be carried out through appropriate well placement as well as water production. More details of the following examples can be found in [1].

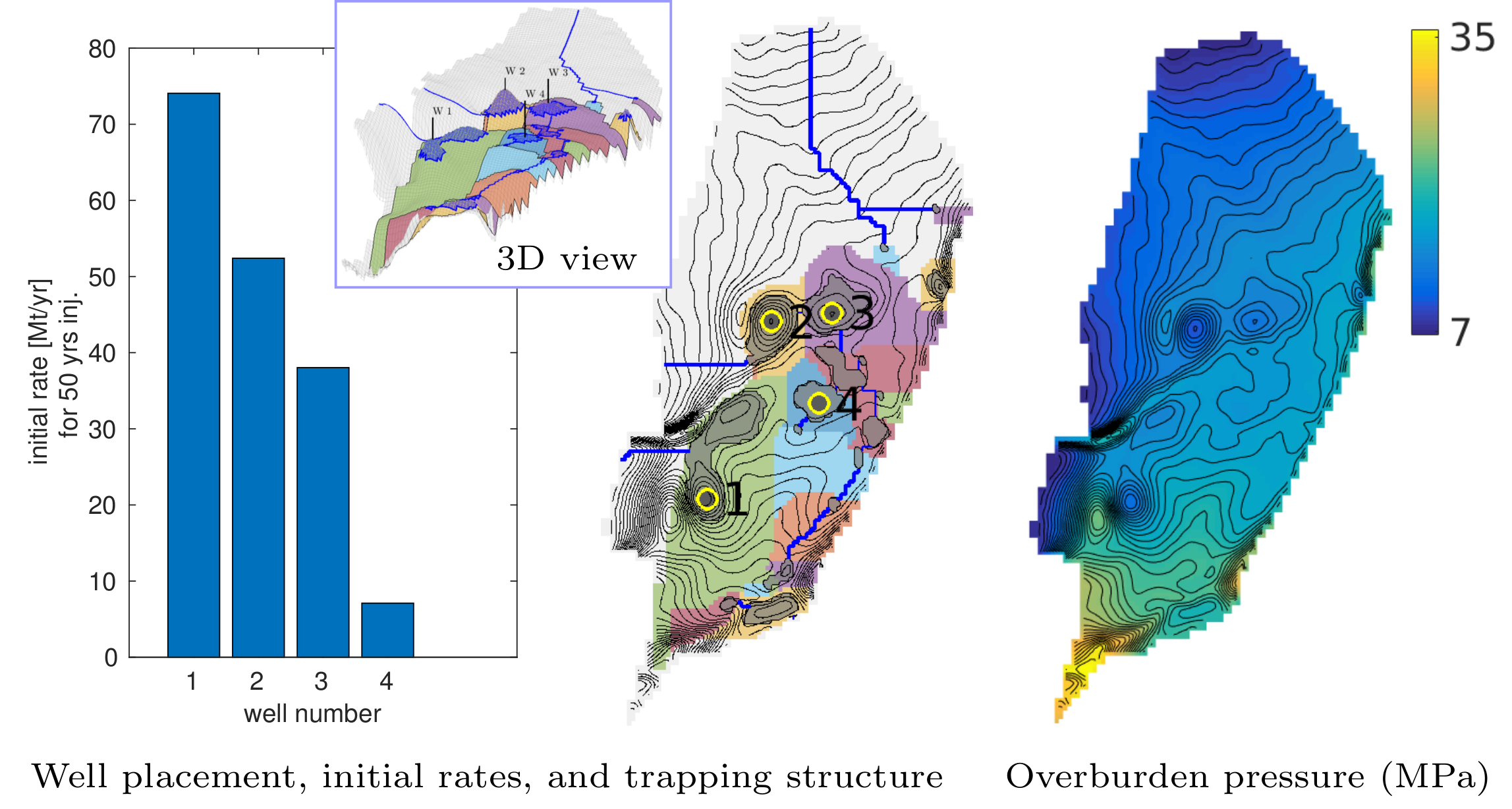

A possible injection set-up in the Bjarmeland formation (Barents Sea)

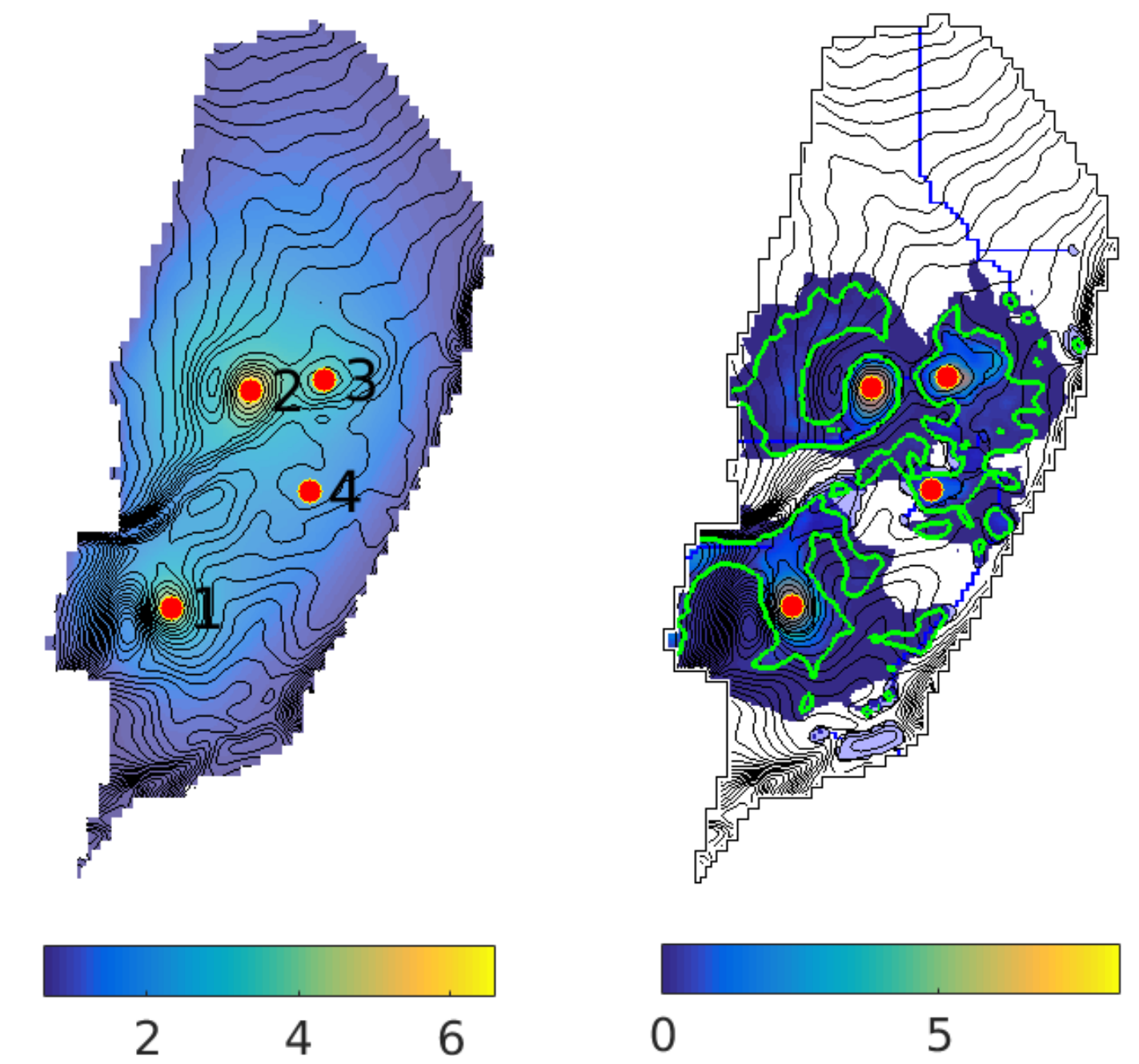

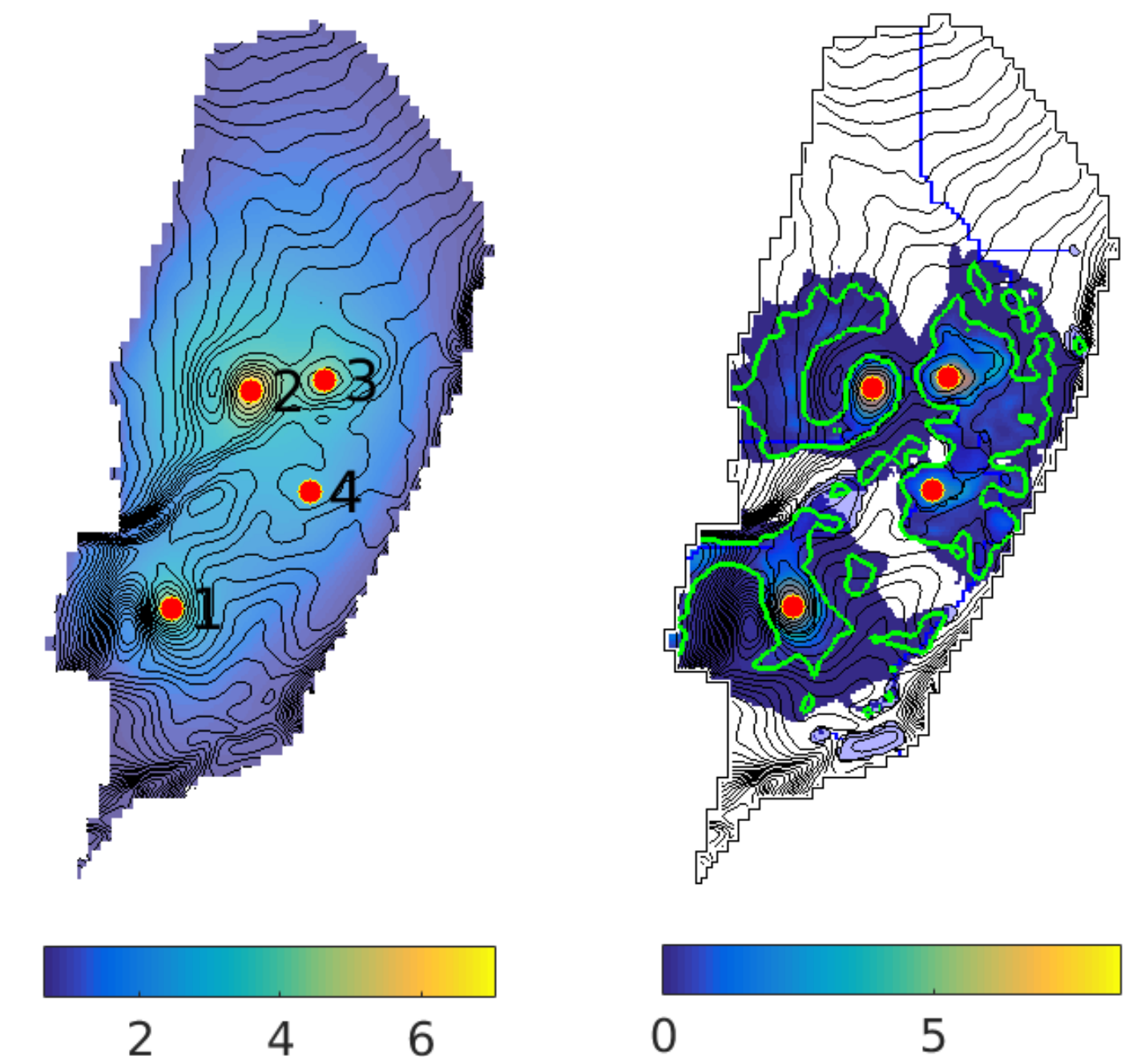

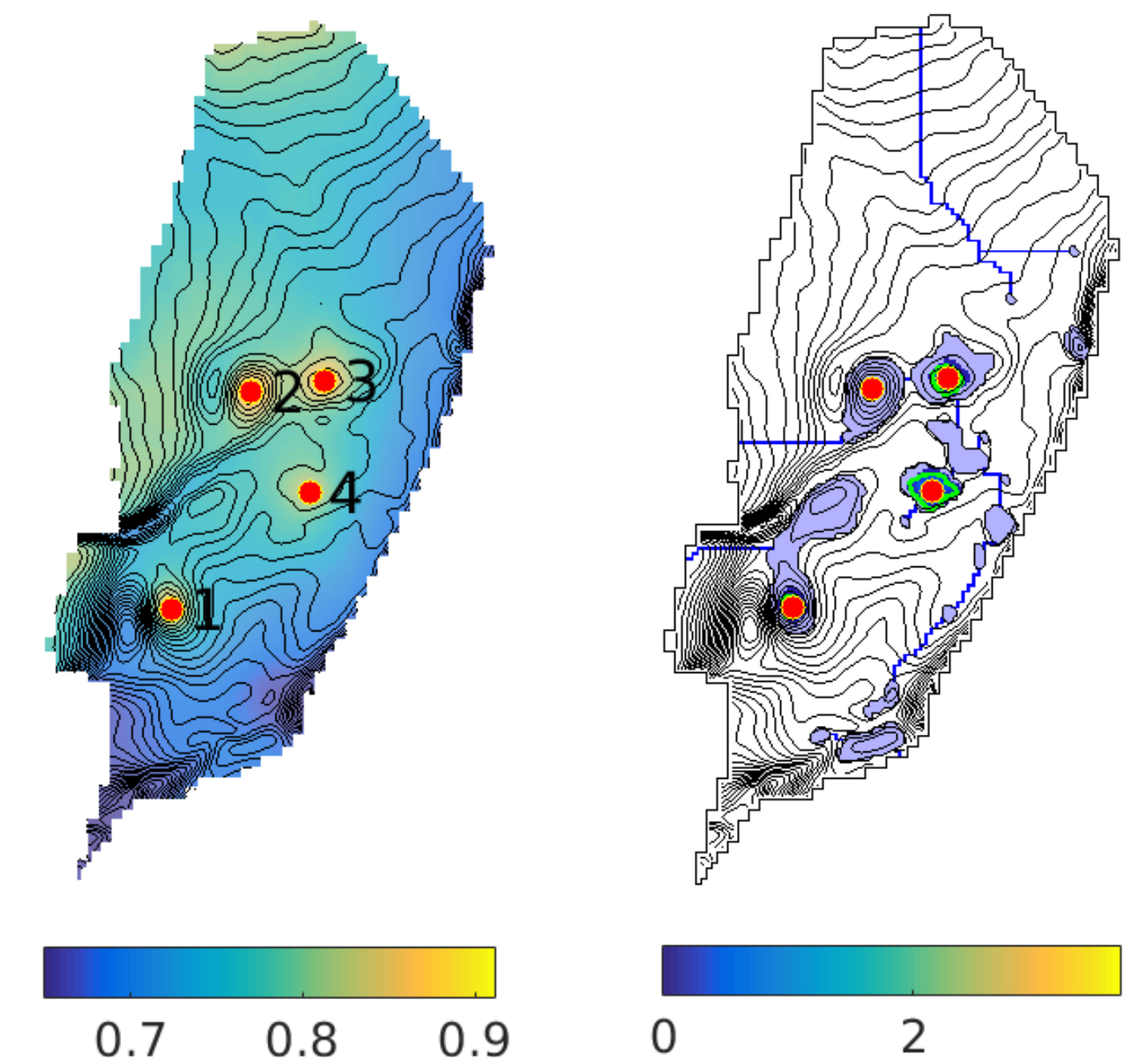

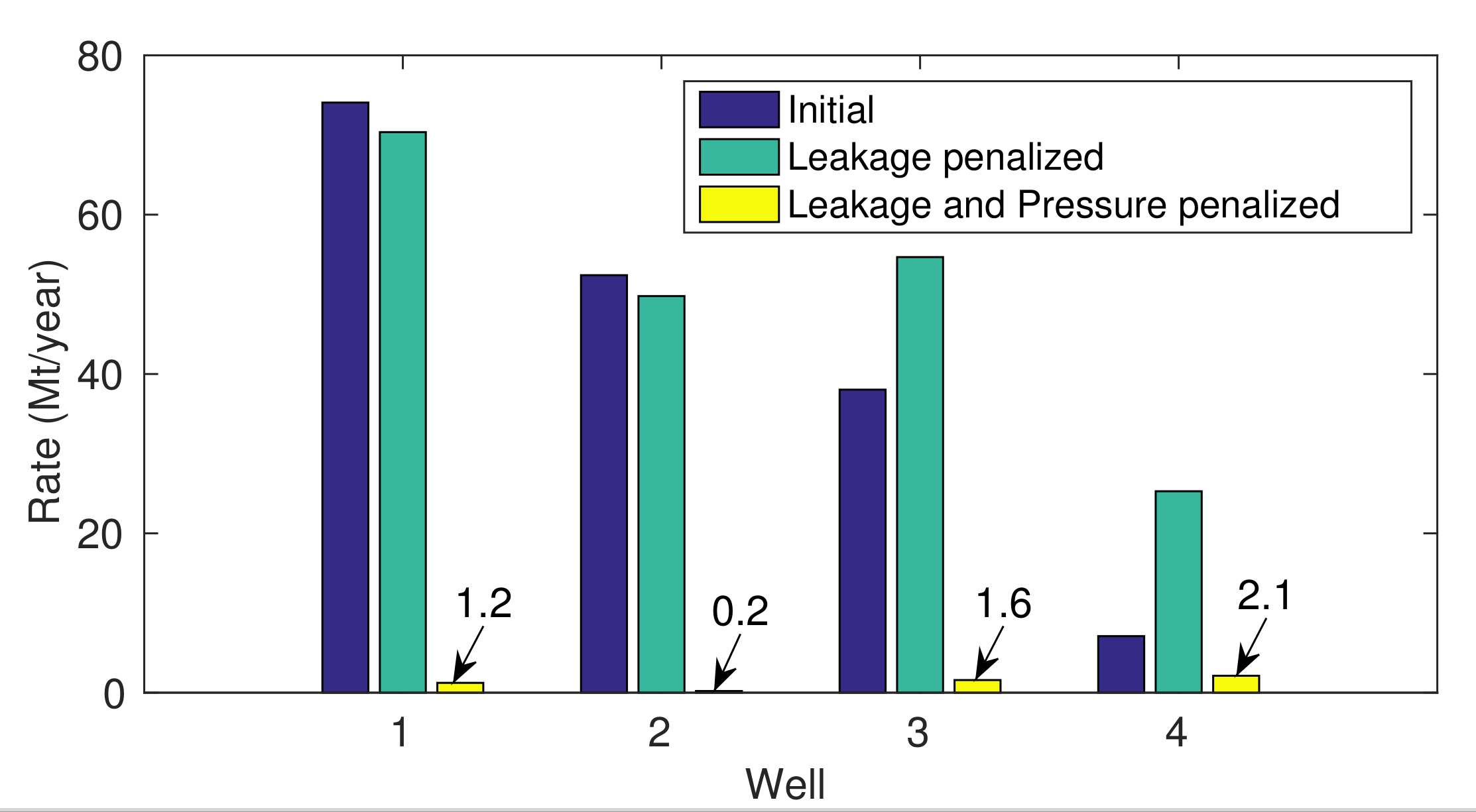

Comparison of initial and optimized strategies

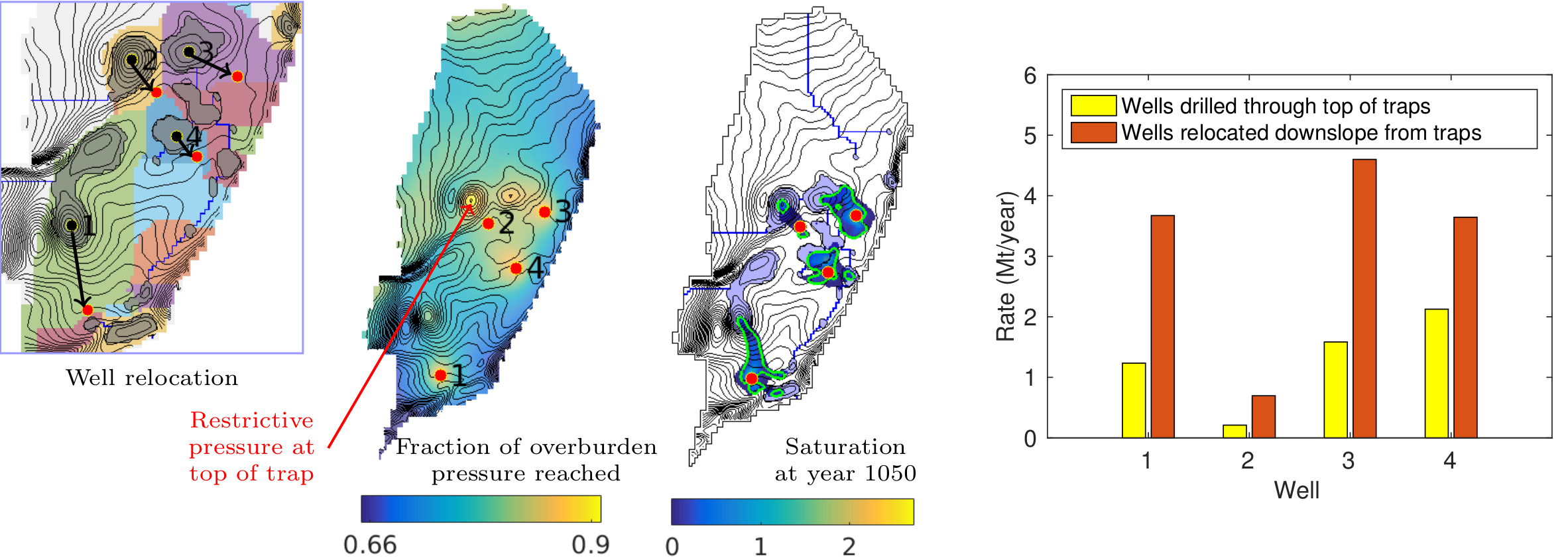

Pressure management strategy 1: well relocation

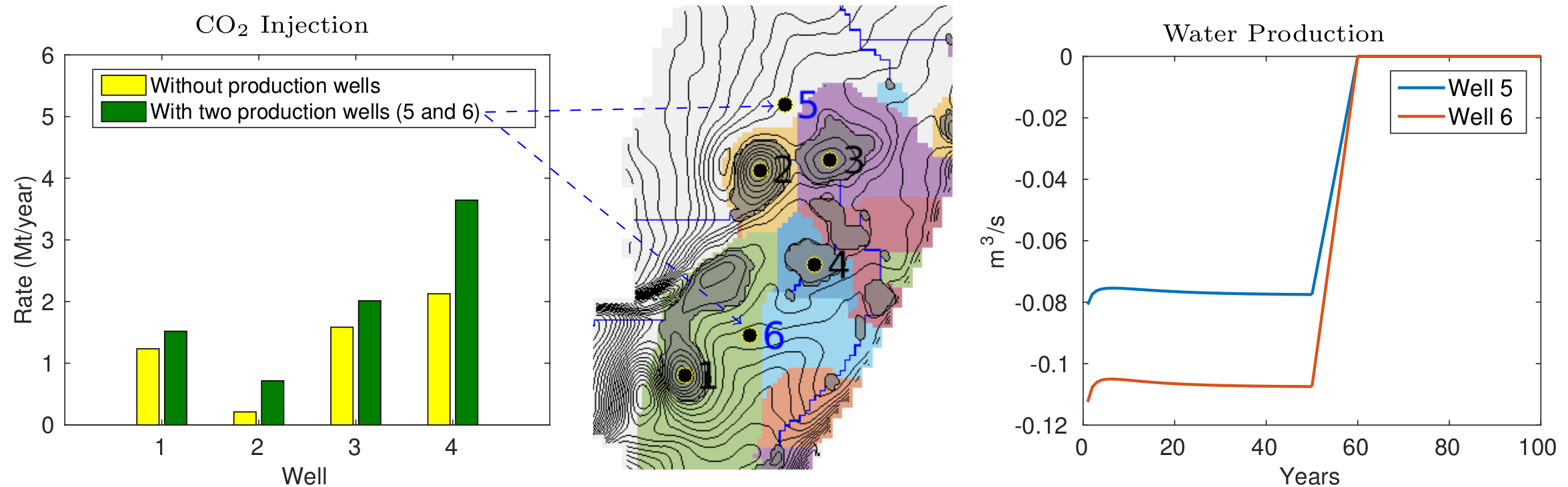

Pressure management strategy 2: include water production wells

Literature1. R. Allen, H. M. Nilsen, O. Andersen, and K.-A. Lie. On obtaining optimal well rates and placement for CO2 storage. ECMOR XV - 15th European Conference on the Mathematics of Oil Recovery, Amsterdam, Netherlands, 29 Aug-1 Sept, 2016. DOI: 10.3997/2214-4609.201601823 |

|||||||||||||||||||||||||