Transport of CO2 in pipelines is a key technology to enable large scale CO2 capture and storage (CCS). For safety and economical issues, it is important to design pipelines where running-fractures will not happen – without overdesigning. Due to different thermodynamical properties, CO2-rich mixtures will exert more forces on the pipe than what would have been the case for natural gas.

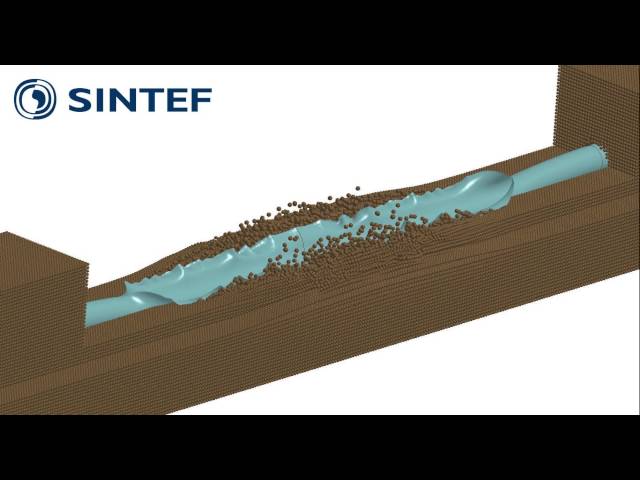

The SINTEF FE-CFD model for fracture-propagation control in CO2 pipelines is the product of a collaboration between experts in fluid and thermodynamics and material mechanics from SINTEF in the research centers BIGCCS and NCCS. The model consists of a finite-element model describing the steel, coupled to the CO2 Dynamics model for the CO2. In addition, any soil surrounding the pipe is described using the smoothed particle hydrodynamics method.

The coupled model has been validated against crack-arrest data for pure CO2 from the CO2PipeTrans project, and for CO2-rich mixtures from the COOLTRANS research programme in the UK – with good results. Further, the model was employed in the Northern Lights project to confirm that the pipeline design is safe, and it is one of the cases considered in a study commissioned by the Norwegian government to evaluate societal effects of energy research.

See also this blog post "Safe CO2 transport pipes is part of the climate solution" for further reading on the coupled model.