Green hydrogen (i.e., hydrogen generated from renewable energy) has been identified as a key priority to achieve the transition to a carbon-neutral society, and the market for hydrogen electrolysers is experiencing rapid, exponential growth.

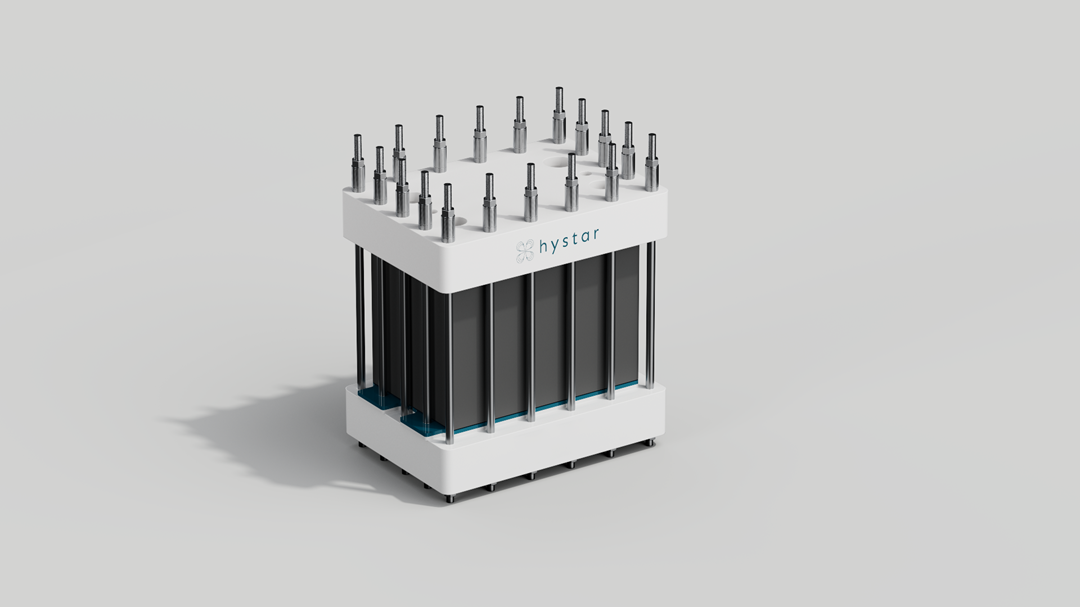

With the aim of reducing the cost of production of green hydrogen, and thereby contributing to the green transition, Hystar AS initiated the Autostack project together with partners Semcon Sweden AB, Tronrud Engineering AS and SINTEF. Autostack is a three-year Innovation Project for the Industrial Sector, supported by the Research Council of Norway. The goal of the Autostack project is to develop a complete industrialization concept for high-volume production of PEM electrolyser stacks.

The most prominent research challenge that this project will solve is how mass production of PEM electrolyser stacks can be performed in a cost-efficient manner with the correct quality. The automated assembly process is complex, with several individual steps per cell. Each cell consists of ultrathin components which must be assembled with very high requirements on positioning and alignment. This is further challenged by each cell component having demanding characteristics, such as being brittle or floppy. The R&D challenge is to find a method and process for assembling the required quality at a high speed in a cost-efficient way. This includes finding methods and processes for setting up a lean supply chain to keep working capital and lead time at a minimum and implementing circular economy models in production and reuse.

In this project, SINTEF contributes with expertise in production logistics, quality management and supply chain management, and will work together with the project partners to develop solutions related to logistics and production management for the future high-volume production. This includes developing concepts and solutions for, among others, inbound logistics, internal logistics, planning and control, quality control and operator support.