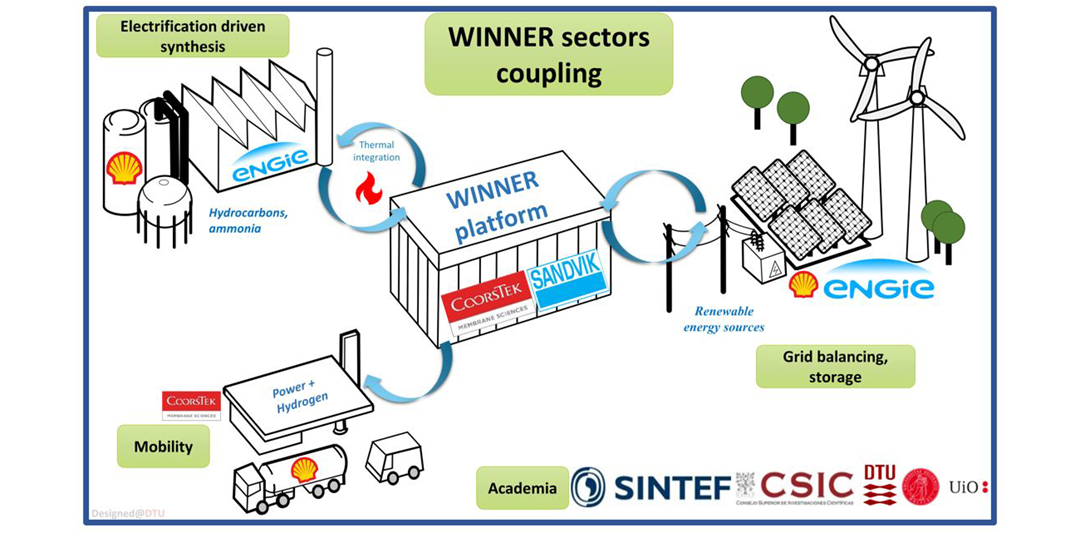

The Winner project will demonstrate three applications: ammonia cracking, dehydrogenation of hydrocarbons, and reversible steam electrolysis. By such, WINNER will create innovative solutions for flexible, secure and profitable storage and utilization of energy in the form of hydrogen and green ammonia, electrification of the chemical industry and sectors coupling.

It builds on the pioneering multidisciplinary expertise of world leading partners in the fields of proton conducting ceramic (PCC) materials and technologies to combine materials science, multi-scale multi-physics modelling and advanced in-situ and operando characterisation methods to unveil unprecedent performance of tubular PCC cells assembled in a flexible multi-tube module operating at industrially relevant conditions.

WINNER will develop innovative cell architectures with multifunctional electrodes and a novel pressure-less current collection system using eco-friendly and scalable manufacturing routes. These activities will be steered by a novel multi-scale multi-physics modelling platform and enhanced experimentation methodologies. These tools combined with advanced operando and in situ methods will serve at establishing correlations between performance and degradation mechanisms associated with both materials properties and interface's evolution upon operation.

Testing of cells and modules will also be conducted to define performance and durability in various operation modes. Techno-economic assessment of the novel PCC processes will be conducted as well as Life Cycle Assessment.

Project partners

The project is coordinated by SINTEF with support from UiO, CSIC, DTU, SMT, CTMS, ENGIE, Shell.

WINNER has received funding from the Fuel Cell and Hydrogen 2 Joint Undertaking under Grant Agreement No (101007165). This Joint Undertaking receives support from the European Union's Horizon 2020 Research and Innovation programme, Hydrogen Europe and Hydrogen Europe Research.