Advanced packaging and interconnects

Contact person

About

Limiting factors of where instrumentation can be placed are often related to size, cost, reliability or performance of the packaging needed for devices. The importance of each factor may vary substantially for various applications demanding us to have a large "tool box" of assembly processes available. Development and characterization of assemblies for demanding environments is our specialty and reliability is the main concern in the majority of our projects. However, low cost processes involving e.g. polymers are also studied by our group.

We target to be more or less fabless with regard to assembly and rather rely on subcontractors who we cooperate with closely. On the other hand, we have a significant selection of equipment for environmental stress testing and characterization at our disposal within SINTEF. We believe in studying the physics of failures in order to improve and predict the life time of existing and future products.

Research Areas

Packaging for extreme miniturization

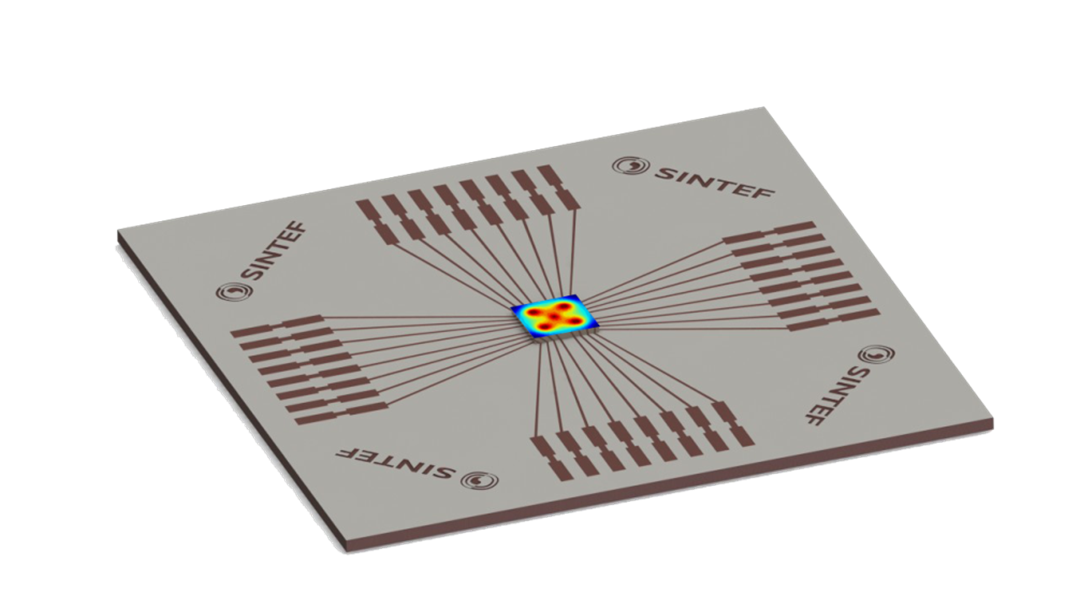

Through our tight collaboration with researchers at SINTEF MiNaLab, packaging of bare dice and 3D integration of MEMS and electronics has become one of our core expertise areas. We assist in the design phase of sensors to assure compatibility with suitable packaging solutions, we give advices concerning assembly and develop new methods when required, and we perform studies of robustness and reliability at both component and system level. Through our profound knowledge about semiconductor devices, both concerning their physical properties and their functionality, we are able to develop innovative packaging solutions for extreme demands.

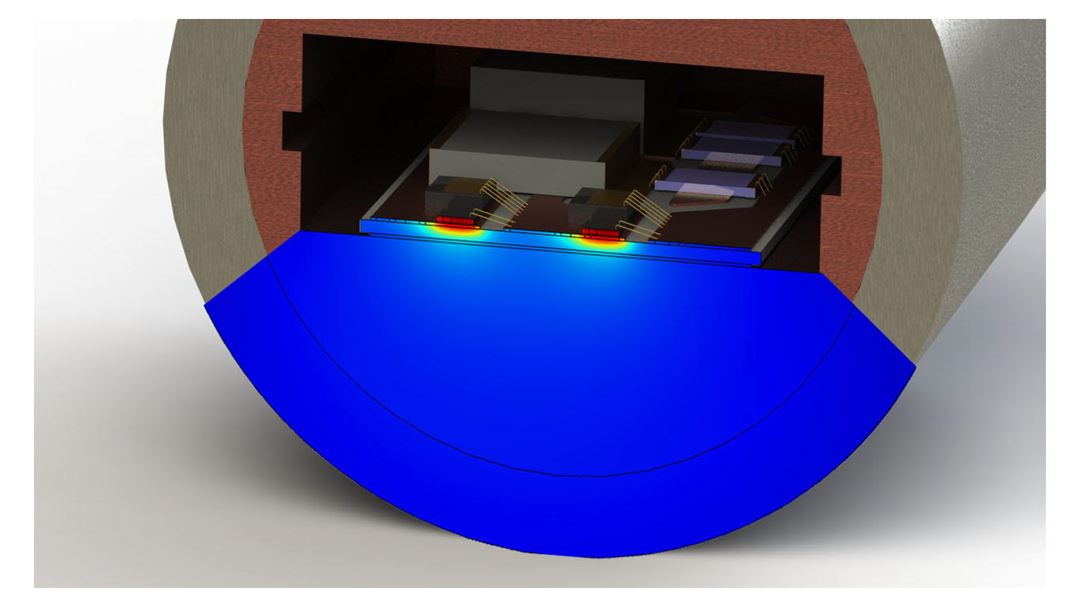

Packaging for harsh environment

The harsh environment packaging team focuses on packaging solutions for high reliability and high performance applications such as for downhole, subsea, automotive, geothermal, air & space industries. Our department has a long pedigree for developing reliable instrumentation system for harsh environments. Our competence in state-of-art packaging solutions has been key for this success. We can support, define and develop suitable technologies and solutions for e.g. interconnects, ceramic circuit boards, encapsulations and thermal management solutions.

Major projects

FLEXTAG, KPN in BIA Norwegian Research Council, 2015-2018, a project initiated to enhance durability and lifetime of fit for purpose flexible smart tags using novel and innovative integration and assembly methods and barrier coating materials

Lab4MEMS, EU ENIAC, 2013-2015, Aiming to establish a European Pilot Line for key enabling technologies on advanced piezoelectric and magnetic materials.

HyperConnect, EU 7th FP, 2013-2015. Functional joining of dissimilar materials using directed self-assembly of nanoparticles by capillary-bridging

Dropin, IPN in BIA Norwegian Research Council, 2012-2015. Robust inlay modules in laminated cards

e-BRAINS, EU 7th FP, 2010-2013. Best-Reliable Ambient Intelligent Nano Sensor Systems.

e-CUBES, EU 6th FP, 2006 - 2009. Develops key micro-system technologies for the 3D integration of various heterogeneous layers.

HISVESTA, EU 7th FP, 2009-2011. Continuation of HASTAC.

HASTAC, EU 6th FP, 2004 - 2008. HASTAC will contribute to increase the safety in all in-flight situations, particularly low visibility situations, by improving the transducers used in Air Data Computers (ADC) for aircraft applications.

CS-Gyro, EU CleanSky, 2011-2012

ESiP, EU ENIAC Call2, 2010-2013, Efficient Silicon Multi-Chip System-in-Package Integration

JEMSiP_3D, EU ENIAC Call1, 2009-2012, Joint Equipment & Materials for System-in-Package and 3D Integration

ReMi, KMB in BIA Norwegian Research Council, 2008-2012, Fine Pitch Interconnect of Microelectronics and Microsystems for use in Rough Environments

HTPEP, KMB in Petromaks Norwegian Research Council, 2009-2012, High Temperature Power Electronics Packaging

SootSens I & II, Nordic Innovation Centre 2008-2010, Development and patenting of a thermal management system for a particle sensor for diesel exhaust systems