The group at SINTEF has operated the large-scale flow loop for experimental verification of the OLGA multiphase pipe flow simulator and more recently development of the new LEDA simulator. The R&D topics cover two- and three-phase pipe flows, sand transport, complex geometries, gas hydrates and more. A long term goal is to couple multiphase flow chemistry with fluid mechanics into next generation Flow Assurance tools.

Experimental activity

At the SINTEF Multiphase Flow Laboratory, more than two decades of operational and scientific experience are united working with multiphase flow phenomena. The group has operated the large-scale flow loop for experimental verification and development of the OLGA simulator and more recently: LEDA. The group is the main user of the various flow laboratories at SINTEF, working on topics such as two- and three-phase pipe flows, sand transport, instrument testing, complex geometries etc.

While traditional experiments on multiphase flow consisted of 1D measurements, new advanced of simulations tools (LEDA) requires increased experimental complexity (2D measurements). The laboratories need therefore to be in constant development. Significant modernisation and increased scientific opportunities are in progress.

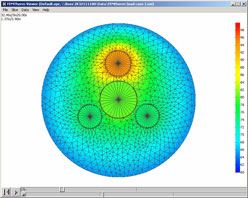

2D temperature distribution between pipes in riser tower estimated using OLGA/FEMTherm software.

Thermohydraulic Studies

With the use of industry standard software, we carry out simulation studies like the following:

- Steady state and transient flow and thermal analysis of oil&gas transfer systems

- Slug analysis including sizing of slug catchers/optimization of controllers

- Shutdown/startup simulations

- Depressurization simulations

- Well and pipeline shut-in/pressurization simulations

- Well flow analysis. Generation of lift curves

- Gas lift optimization

- ESP pump sizing and optimization

- Gas lift valve leak detection by use of transient PVT-simulations

- Gas line liquid surge analysis

- Pipeline leakage analysis

- Process simulation and design

- CFD simulations

Well and production technology

- Well productivity and stimulation

- Well testing

- Well intervention

- Sand management and control

- Operability studies