|

|

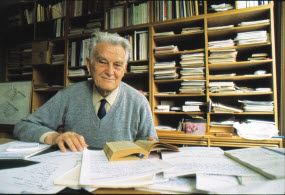

In the old days, CO2 was a normal working medium in seagoing air-conditioning systems. Professor Gustav Lorentzen (1915-95) took CO2 technology an important step further when he hatched out a method for optimising the pressure in systems of this sort. Photo: Jens Søraa |

On a winter day in 1987, a young engineer had made up his mind. In a solid building on the eastern edge of the Gløshaugen campus, high above a football pitch with the not particularly attractive name of “Death Valley”, Petter Nekså was on his way out of the door.

He aimed to study for a doctorate and was soon climbing the steps to Professor Gustav Lorentzen’s office, in order to discuss a suitable topic.

Hot and cold degrees

At the time, Nekså was working in SINTEF’s Refrigeration Engineering Section.

At the Norwegian Institute of Technology, on the next floor, the sign on the door read “Department of Refrigeration Engineering - a misleading name, in the view of non-specialists, because these groups also work on heating technology.

But in fact, heat pumps and refrigeration systems are actually two aspects of the same process.

Focus on “work-horses”

Lorentzen and Nekså wanted to talk about a group of what are known as “working media”, the work-horses of heat pumps and refrigeration systems.

These are materials that flow in a closed loop in such systems, absorbing heat at one point in the curcuit and releasing it at another. They are all fluids, selected on the basis of their boiling points. Even cold outdoor air can bring certain of these media to the boil if the pressure is right.

Capable of removing heat…

Boiling “steals” heat from the surroundings, enabling the refrigeration system to do its job, which is to remove heat.

Boiling turns the liquid in the closed loop into a gas, which is then compressed in an electric compressor unit, raising the temperature of the gas in the process.

Then the gas is cooled, releasing heat; to the outdoor air, for example, if the heat is to be removed.

and of supplying it…

However, the heat can also be transferred to water for taps or radiator systems. This is how a heat pump delivers its product: heat, perhaps collected from the outdoor air, but now raised to a temperature that will make it useful.

When the gas releases its heat it turns back into a liquid, either partially or completely, and passes through a pressure reduction valve to its point of departure, where the whole process starts all over again.

Many substances in their sights

The substances that were being discussed by Lorentzen and Nekså have interesting properties for heat pumps that have to raise temperatures by large amounts.

The two agreed that Nekså’s doctorate should deal with this group, among them CO2. However, the two did not discuss either heating tap-water or air-conditioning systems for cars. At least, not at that point.

Nevertheless, it would not be very long before both of these applications became burning issues among the scientists in Trondheim.