Research group Process Metallurgy and Raw Materials

Our ambition is to develop innovative and novel solutions for producing metals. Through fundamental research and process improvement and development, we aid the metallurgical industries in achieving ambitious goals such as CO2-free processes, improved energy efficiency and process circularity.

Contact person

Research areas and infrastructure

Our main research areas

- Silicon and ferroalloy production processes

- CO2-free metal production, e.g. by the use of alternative reductants such as biocarbon and H2

- Plasma technology

- Gas emissions and diffuse emissions

- Raw material characterization and process impact

- Material valorisation and reuse

- Reactive multiphase flow

Infrastructure

- 180 kW submerged arc furnace

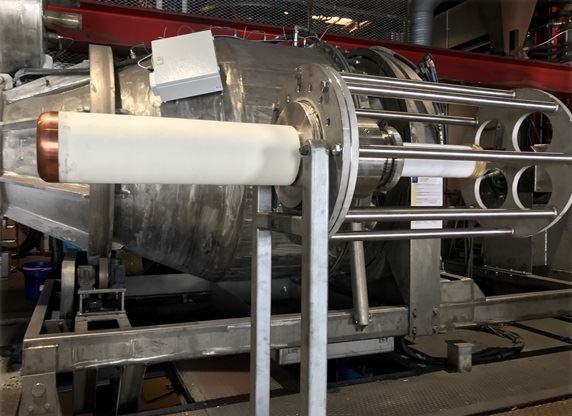

- Plasma furnaces, lab scale and pilot scale

- Variety of heating furnaces, operating under different gas atmospheres

- Agglomeration equipment

- Modelling software

- Gas analysis methods (FT-IR, MS, Micro GC)

- SiO reactivity test

Employees in the research group for Process Metallurgy and Raw Materials