Detailed and accurate characterization is especially important for proper utilization of inhomogeneous and low quality biomass and waste feedstocks, to prevent operational related problems, optimize conversion processes and design conversion systems.

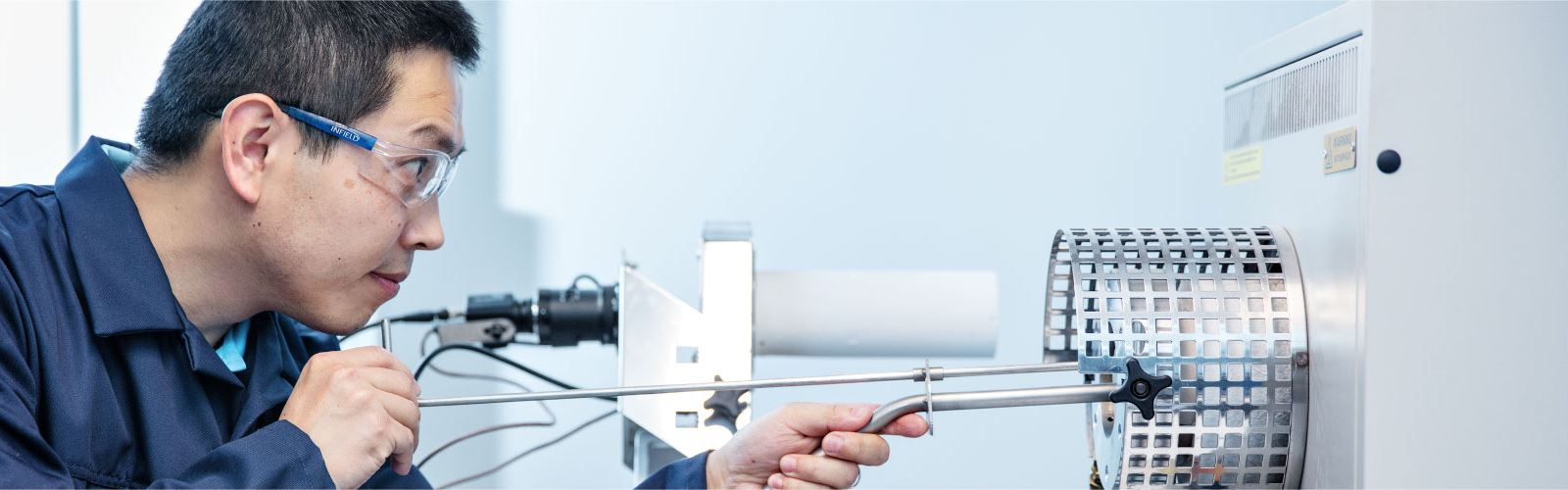

SINTEF carries out full characterization of biomass and waste feedstocks in terms of physical, chemical, elemental, calorific and ash related properties according to different international and national standards. Moreover, we have unique and advanced laboratory facilities for investigating complex decomposition behaviors of biomass and waste feedstocks under different conditions, monitoring products compositions and evaluating reaction kinetic characteristics of the feedstocks.

Also included in our arsenal of analytical equipment is the possibility to measure both particle and gaseous emissions.

For gases it includes major gas species released during thermal conversion such as CO2, H2O, CO, CH4, H2 etc. and minor species such as NOx and NOx precursors (NH3 and HCN), SOx and SOx precursors (H2S and COS), siloxanes and many more. For particles, we use gravimetric impactors that are able to separate particles in the size fractions PM10, PM2.5 and PM1.0. In addition, we have an Electrical Low Pressure Impactor (ELPI) for the measurement of particle number concentration in 10 different size distributions. The ELPI can also be operated gravimetrically, and collected particles can be analyzed with respect to e.g. elemental composition using SEM-EDX.

We work within these areas:

- Accurate weight measuring (down to µg)

- Conditioning and weathering of biomass and waste feedstocks under well controlled conditions

- Proximate analysis of biomass and waste feedstocks

- Moisture content

- Volatile matter (VM) content

- Fixed carbon (Fix-C) content

- Ash content

- Ultimate analysis of biomass and waste feedstocks

- Carbon (C)

- Hydrogen (H)

- Sulfur (S)

- Nitrogen (N)

- Oxygen (O)

- Calorific value

- Ash composition (present in element or oxide form)

- Major elements: Si, Ca, K, Na, P, Al, Mg, S, Fe, Cl

- Minor elements: Zn, Pb, Ba, Ti, As, Cd, Hg

- Ash melting and fusion points under inert, reducing and oxidizing conditions

- Grindability and specific grinding energy

- Particle size and shape assessment

- Comprehensive empirical indexes and thermal equilibrium calculation program for predicting ash sintering, agglomeration, slagging and fouling and relevant ash chemistry

- Assessment of thermal conversion behaviors of biomass and waste feedstocks under well controlled conditions

- Inert, reducing and oxidizing atmosphere

- Atmospheric and pressurized (up to 50 bar) condition

- Low and high heating rate

- Wide temperature range

- Characterization of solid, gas and liquid products from thermal conversion of biomass and waste feedstocks

- Kinetic evaluation of thermal behavior of a feedstock for detailed understanding of its decomposition process and possible up-scaling options and implications

- Gas concentration measurements with Micro-GC, including a special Micro-GC with a Deferential Mobility Detector (DMD) for the measurement of H2S and COS at ppb levels.

- Gas concentration measurements with several FTIRs (Fourier Transform Infrared Spectroscopy) for the measurement of most gaseous species found in the flue gas or syngas from either combustion, gasification or pyrolysis processes. We also have a method for measuring siloxane compounds from biogas production processes.

Methods

We are specialists in using a wide range of advanced analytical facilities and instruments to characterize properties of various biomass and waste feedstocks. We have extensive knowledge and experience about characteristics and thermal conversion behaviors of forest, agricultural, municipal and industry sources feedstocks.

Why choose SINTEF?

SINTEF offers unique and advanced laboratory facilities for characterization and evaluation of thermal behaviors of biomass and waste feedstocks. Together with both national and international industry and research partners, we utilize as well as develop, refine and validate reliable and cost-effective methods to characterize various biomass and waste feedstocks. We have through decades gained extensive knowledge on feedstock characteristics, pretreatment and upgrading approaches, thermal conversion behaviors and potential operational related challenges.