Consortium

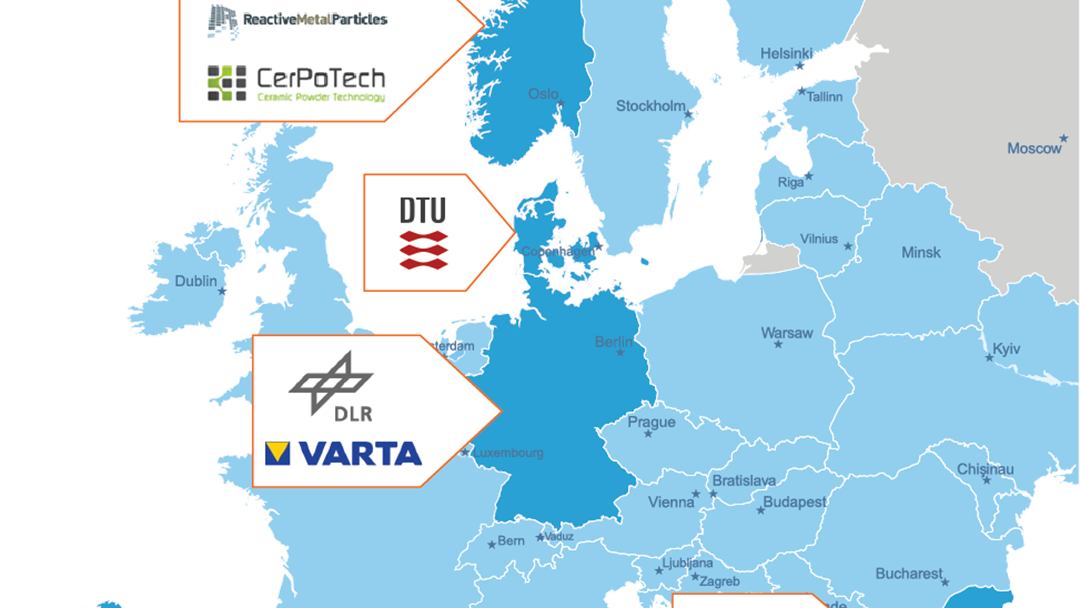

Nine European partners are joining forces to develop a cost efficient zinc air-secondary battery for efficient energy storage. The three years, €6.6 million ZAS project is supported by The Horizon 2020 in the NMP program 13 and involve 650 person months of total work effort. The ZAS consortium was assembled to gather complementary skills, expertise and resources required to achieve the project's objectives and reduce the time to market of the developed zinc-air battery. The consortium consists of partners from five European countries; one university (DTU), four research institutes (SINTEF, CIDETEC, DLR and IEES), two SMEs (CERPOTECH and RMP) and two industrial companies (VMB and ABENGOA). The partners' core competence cover the whole value chain from fundamental materials research (theoretical modeling and material development) to industrial optimization, manufacturing and testing of zinc-air batteries under given and realistic operating conditions.

- STIFTELSEN SINTEF, Norway

- DANMARKS TEKNISKE UNIVERSITET, Denmark

- DEUTSCHES ZENTRUM FUER LUFT - UND RAUMFAHRT EV, Germany

- REACTIVE METAL PARTICLES AS, Norway

- FUNDACION CIDETEC, Spain

- ABENGOA, Spain

- INSTITUTE OF ELECTROCHEMISTRY AND ENERGY SYSTEMS, Bulgaria

- Ceramic Powder Technology AS, Norway

- VARTA MICROBATTERY GMBH, Germany

SINTEF

SINTEF, based in Norway, is one of the largest independent contract research organizations in Europe with about 2100 employees. It is a multidisciplinary organization with over 90 % of the income from commissions from industry and public administration and from project funding. SINTEF Materials and Chemistry (MC) is one of SINTEF's research institutes and is participating in this project represented by the department of Sustainable Energy Technology. SINTEF MC works closely with industry in the development of advanced materials, products, processes and new tools, and seeks out new, environmentally friendly processing methods that will increase productivity and raise quality standards. The department of Sustainable Energy Technology is involved in multiple projects related to energy storage and battery technology.

Main contribution in ZAS:

- Project coordination

- Develop and produce oxide-based materials for the bifunctional cathode

- Electrochemical characterization and selection of the optimal electrode based on its lab-scale electrochemical performance

- Structural characterization of material and electrodes

Contact person: Mari Juel

Fundación CIDETEC

CIDETEC, based in San Sabastian, Spain, is a Technology Centre belonging to the IK4 Research Alliance, specializes in generating and transferring knowledge and technology in the areas of Materials (Nanomaterials, Biomaterials and Sensors), Surfaces (Ceramic and Metallic Coatings, Surface Processing) and Energy (Batteries, Fuel Cells and Materials for Energy systems). Their mission is to enhance business competitiveness and capacity for innovation through the development of new products and processes. They aim to become strategic allies of their clients, helping them define their innovation strategies and providing information and technology solutions that add value to their businesses. CIDETEC had an annual turnover of 10M€ in 2013 and at the present time employs a highly qualified staff of 125 people, 50 % of them PhDs.

Main contribution in ZAS:

- Selection of materials for electrodes and electrolyte

- Electrode engineering and cell design

- Participate in designing the modules and assembly of prototypes

- Involved in the development of accelerated testing protocols to evaluate performance, lifetime and safety.

Contact person: Alberto Blázquez

Deutsches Zentrum für Luft-und Raumfahrt (DLR)

DLR is the national aeronautics and space research center of the Federal Republic of Germany. Its extensive research and development work in aeronautics, space, energy, transport and security is integrated into national and international cooperative ventures.

DLR has approximately 8000 employees at 16 locations in Germany. The DLR Institute of Technical Thermodynamics is active in the fields of renewable energy research and technology development for efficient and low emission energy conversion and utilization with two sections and around 75 persons. The Department of Electrochemical Energy Technology (ECE) has long-term experience in production and characterization of electrochemical systems and the Department of Computational Electrochemistry (CEC) has strong expertise in modeling and simulation of fuel cells (SOFC, PEFC; DMFC and AFC) and batteries (Lithium-ion, Lithium-Sulfur and Li-air batteries).

Main contribution in ZAS:

- Production, characterization, and experimental validation of bi-functional air catalyst and gas diffusion electrodes

- Improve the cathode design and optimize the zinc-air cell based on mesoscopic modelling of Zn anode dissolution and catalytic behavior in the cathode

Contact person: Norbert Wagner

Technical University of Denmark (DTU)

DTU is a leading Scandinavian technical university and part of the Euro Tech University Alliance and Nordic Five Tech. The University has extensive expertise within the areas of battery materials and mechanisms, heterogeneous and electro-catalysis as well as computational materials design.

The DTU activities in ZAS are led by the Department for Energy Conversion and Storage (DTU Energy Conversion). They are focusing on the development of new technologies and materials for energy conversion and storage, i.e. fuel and solar cells, membranes, magnetic refrigeration and thermoelectrics, electrolysis and synthetic fuels, hydrogen storage and batteries. The Center for Atomic scale Materials Design (CAMD) is a world leading center in the development of electronic structure theory to understand the properties of materials and use the insight to design new functional nanostructures.

Main contribution in ZAS:

- DFT simulations of the reaction mechanisms for oxygen evolution and oxygen reduction at the air cathode

- DFT simulations of the dissolution processes at the zinc based anode

- Quantitative DEMS measurements for assessing electrolyte stability

Contact person: Tejs Vegge

Institute of Electrochemistry and Energy Systems (IEES)

IEES is located in Sofia, Bulgaria. It has 100 employees, 48 of them scientific staff. IEES's core competences are: R&D of electrochemical energy sources; electrochemical materials science; nano-scaled materials, electrochemical methods, techniques and instrumentation; e-Science. The activities of IEES are concentrated in two Joint Thematic Platforms: (i) Fuel Cells and Hydrogen and (ii) Batteries. During the last 10 years IEES has had more than 250 contracts with different institutions and companies. IEES received the Centre of Excellence (FP 5) and the highest evaluation score in the audit from ESF and ALLEA: AAA for (i) internationally competitive work, (ii) highly relevant socio-economic impact and (iii) high prospects. In FP7 IEES has 5 projects in Energy (one in batteries and four in fuel cells).

In this project IEES enters with 3 departments; Department of Electrocatalysis and Electrocrystallization , Department of Nanoscaled Materials, and Department of Electrochemical Methods.

Main contribution in ZAS:

- Development of electrodes with improved performance

- Cell design and assessment

- Electrochemical characterization and testing

- Feeding the modelling with the necessary electrochemical parameters

Contact person: Daria Vladivoka

Ceramic Powder Technology (CERPOTECH )

CERPOTECH was founded as a spin-off company from the Norwegian University of Science and Technology (NTNU) in 2007. The main products are complex oxide powders of high quality produced via spray pyrolysis from environmentally friendly aqueous precursors. The company built up semi-industrial production facilities during 2013 with the ability to serve both academia and industry. CERPOTECH's current facility has an annual production capacity of several metric tons of powder with further increase planned.

CERPOTECH has developed protocols for more than 50 different oxide materials from combinations of more than 40 elements. The exceptional ability to tailor make high quality complex oxides that are commercially not available and capability of delivering raw materials with the same properties for laboratory-size samples as for industrial batches, puts CERPOTECH in a unique position as a highly qualified developer and supplier for advanced materials oriented projects.

Main contribution in ZAS:

- Synthesis of cathode material based on oxides by spray pyrolysis

- Investigation of the possibility to scale up the production of favorable oxides to industrially sized powder batches

Contact person: sophie.weber@cerpotech.com

Contact person: Sophie Labonnote-Weber

VARTA Microbattery GmbH (VMB)

VMB is a medium size battery manufacturer at Ellwangen in the southern part of Germany. VMB employs nearly 750 persons in Germany and approx. 2000 worldwide. The entire Research, Engineering and Production of the electrochemical cells are done at Ellwangen.

The product range of VMB contains small batteries for portable devices, like Hearing Aids, Computers, Car Electronics and Heat Calorimeters. In the last years this portfolio was extended to automotive traction batteries in the Joint-venture Volkswagen VARTA Microbattery Forschungsgesellschaft mbH (VWVM) and storage batteries in the order of 5 – 13 kWh in the VARTA Storage GmbH (VS).

VMB has a lot of experience in manufacturing of zinc air primary button cells for hearing aids. They also checked the possibility of making rechargeable zinc batteries. The results of several entities, like PSI, ZOXY, REVOLT and EOS, was investigated as far as possible.

Main contribution in ZAS:

- Investigate the new materials in full-cells in button size and test the successful materials in button full-cells

- Produce final demonstrators having > 100 cm² of electrode

Contact person: Martin Krebs

ABENGOA

ABENGOA is one of the leading Spanish industrial engineering, construction and maintenance companies in the energy, industry, services, environment, transport and communications sectors. It is operating in more than 25 countries with more than 2.500 highly qualified staff.

ABENGOA's R&D Department is developing activities within the following fields including Energy Storage, Communications and Smart Grids, Power electronics, Electromobility and Zero-emissions.

In recent years energy storage has been prioritize research area for ABENGOA and has resulted in the creation of Energy Storage Program. This has brought the company strategy closer to market necessities. Energy storage plays an important role in the new electrical model where efficiency, savings and "intelligence" regarding consumption and generation are given priority.

Main contribution in ZAS:

- Life-cycle assessment (LCA) of the ZAS cell structure as well as the whole energy storage system.

- Definition of specifications and test procedures of module and operating conditions

- Calculating Levelized Cost of Energy (LCOE) for different scenarios of hybridization of ZAS technology with other energy storage technologies on the market.

Contact person: Sergio Sáenz Robles

Reactive Metal Particles AS

Reactive Metal Particles AS based in Norway was founded in 2010, in search of solving the scalability and cost challenges related to the production of fine and ultrafine metal powder. Reactor components are based on well-known materials and the reactor design is scalable. IPR for the technology is secured. The key production mechanism has been successfully proven and demonstrated through a prototype reactor for zinc. The powder is produced in a close reactor and feed directly into a solvent. The product is slurry and avoids SHE challenges related to production, handling and transport of fine and ultrafine powder. More than 150 kg zinc powder has been produced. Currently RMP is managing a R&D project with three major industrial players in the anti-corrosive coating market. SINTEF and STAMI are the R&D contractors. The goal of the project is to develop improved zinc coating for the offshore and marine sector.

Main contribution in ZAS:

- Produce zinc powder tailored for the zinc anode

Contact person: Rita Glenne