Our staff conducts projects in close contact with national and international industry, and collaborates with other national and international research institutes and universities. We perform contract research for all main industry areas, from oil and gas to renewable energy and high volume production of mechanical components/products.

Our main focused areas are:

- Welding of metals

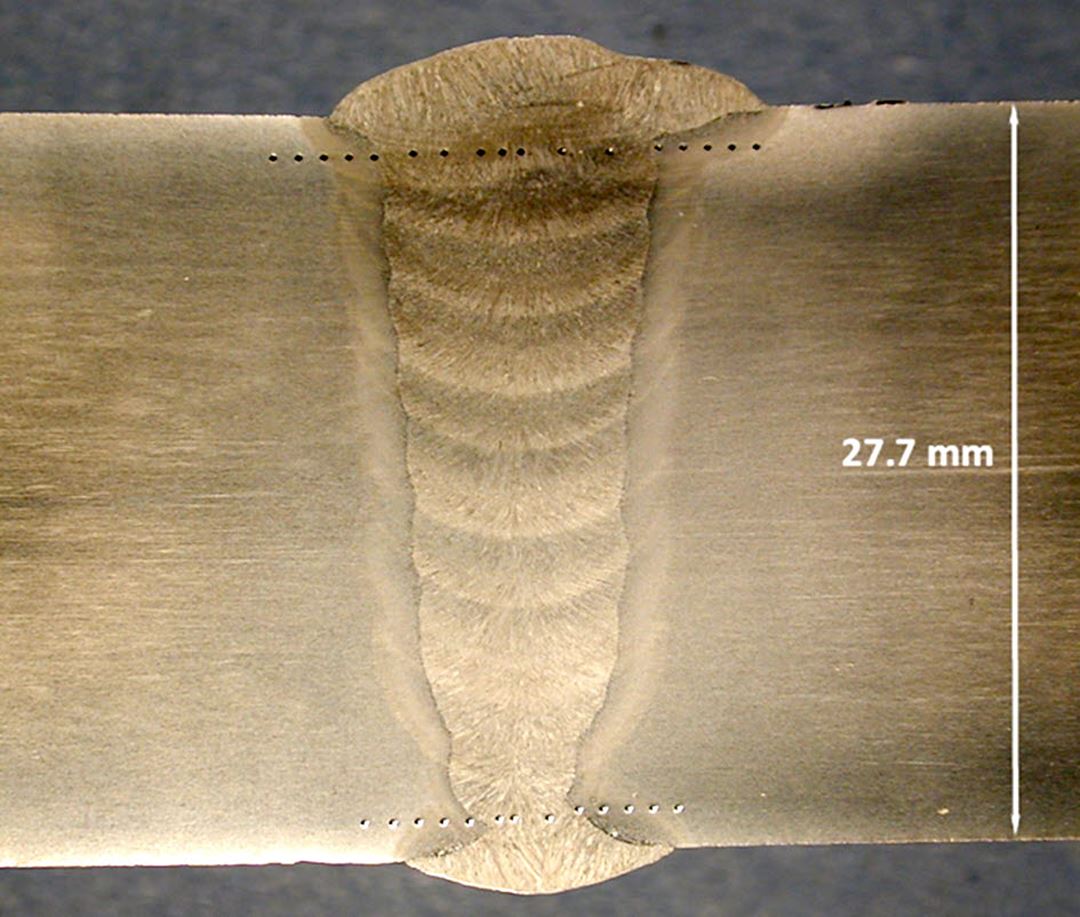

- Hyperbaric welding of pipelines

- Development and qualification of welding procedures

- Welding metallurgy

- Welding technology, techniques and processes

- Mechanization/automation

- Residual stresses; measurements, modelling and implication

- Welding of polymers

- Mechanical joining

- Stud welding and riveting

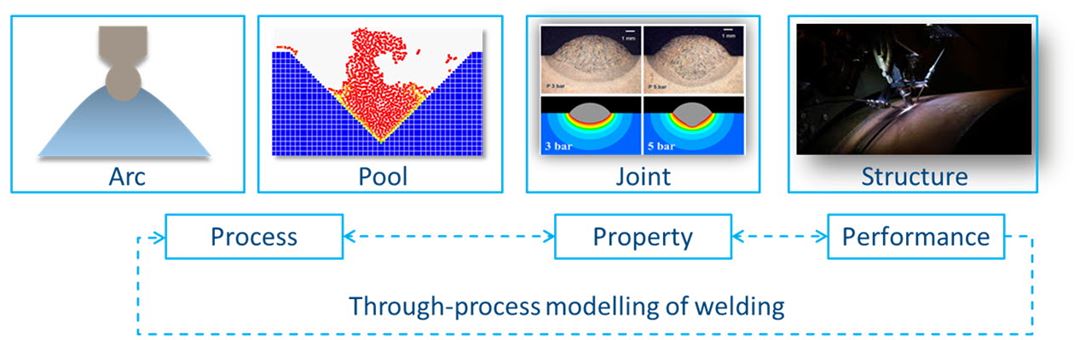

- Numerical modelling and testing

- Adhesive bonding

- Brazing and soldering

- Joining of dissimilar materials

Typical projects are:

- Development and qualification of welding procedures

- ECA (Engineering Critical Assessment) of weldments

- Characterization and mechanical/fracture mechanical testing of welds and joints

- HISC (Hydrogen induced stress cracking) and corrosion testing

- Fatigue and corrosion fatigue

- Testing and modelling of polymers and composites, and joints

- Failure analysis of joints and components

- Material selection for special environments (corrosion, etc.)

- Evaluation on the basis of standards/specifications

- Heat treatment of welds (incl. PWHT, post weld heat treatment)

- Development and use of numerical tools

Examples of projects: