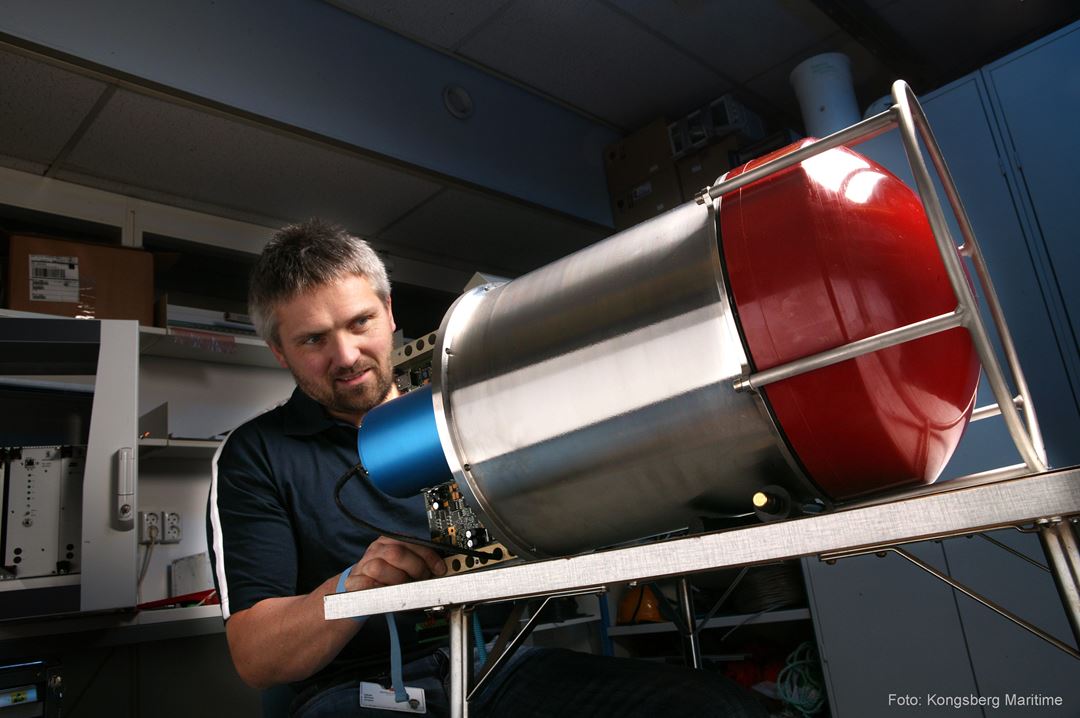

Kongsberg Maritime Subsea (KMS) in Horten has positioned itself as a world leading premium manufacturer of hydroacoustic solutions for marine robotics, subsea navigation and underwater mapping. Over the last fifteen years, however, this competitiveness has been sharply challenged by competitors in low-cost countries. KMS and corporate strategic suppliers will in the coming years respond to this by offering a wider range of products addressing more customer segments.

We are on the marks of the fourth industrial revolution – Industry 4.0. Characterized by, among others, increased digitalization and automation, Industry 4.0 is expected to overturn traditional business models and supply chains. The overall idea in SmartChain is that increased digitalization and automation in the core value chain enables competitive production of volume and premium products for different market segments.

The main goal of the project is to develop methods and solutions that ensure efficient supply chains with a high degree of technology-enabled production, including planning and control. This will be realized through the following objectives:

- Develop a strategic concept for efficient supply chains with high degree of automation and digitization

- Develop a method for integrating high-volume automated production of premium products with lower volume technical prototypes in a laboratory environment

- Develop a methodology for integrated development of production-friendly products in the core value chain

- Modeling an integrated system for real-time monitoring and control, which effectively manages material flow and unexpected events in the supply chain

- Testing and documenting project results in a demonstrator for integrated and automated manufacturing in the value chain perspective.

The project is carried out by KMS in cooperation with core suppliers Norautron and Oswo, the IT company Virinco, and research partners SINTEF Technology and Society and SINTEF Raufoss Manufacturing.