Geothermal energy is today recognized as a weather independent and stable energy source with significant potential compared to other resources like hydropower, wind, and solar energy. The high cost of drilling deep wells in hard rock formation is the main cost driver and the key bottleneck for the realization of widespread exploitation of deep geothermal energy (GTE). Norway has a unique position in the world, i.e. an enormous expertise in environmentally-friendly, cost-effective drilling accumulated during the decades of safe and successful hydrocarbon production. This gives Norway an advantage and allows it to take the lead in the development of cost-effective technologies for deep geothermal drilling.

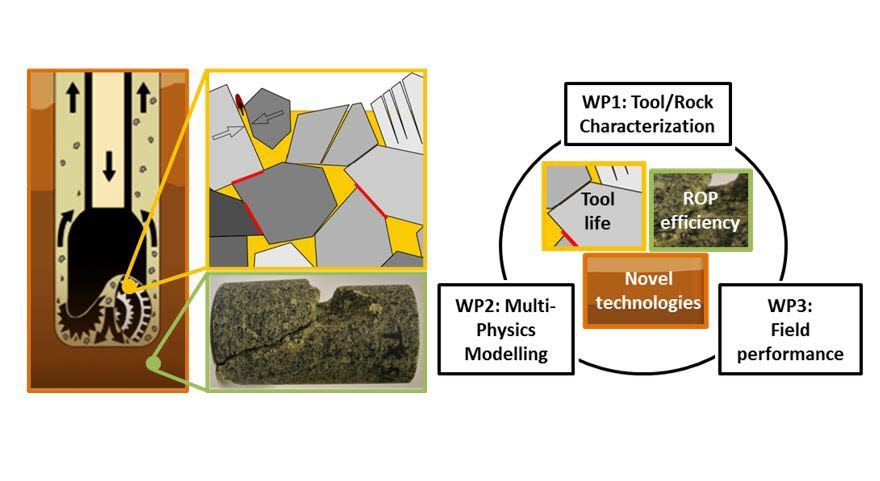

Major cost reduction in deep hard rock drilling must be achieved by a combination of increased ROP efficiency (i.e. more efficient rock breaking and cutting transport), significant reductions in tool wear and equipment failure with associated downtime, and by the introduction of innovative technologies. To make advances in accordance with these challenges, the following scientific research questions will be addressed:

- What are the tool/rock materials response under representative loading and relevant environmental conditions?

- What are the proper modelling tools and strategies to represent the rock breaking process, the rock debris removal and the tool behaviour and degradation?

- How can we estimate the drilling performance in field conditions?

- What are the limitations of existing technology and what is the potential for introduction of radical, new technologies?

To fulfill the main objectives, the four following research axes will be followed:

- To establish a well-documented and peer-reviewed multiscale and multi-physics methodology to capture the fundamental mechanisms induced by tool/rock interactions

- To gather national and international actors along the industrial value chain, including selected technology companies and well-established enterprises, and to promote the exchange of information

- To create arenas that stimulate research-based innovation, enables industrial uptake of research results and supports the field demonstration of innovative drilling technologies

- To reduce the hard rock drilling cost by improved rate of penetration, reduced tool wear, and innovative drilling solutions

The project will also create arenas that gather national and international actors along the industrial value chain, including selected technology companies and well-established enterprises to supports the field demonstration of innovative drilling technologies. The knowledges and technology developed within this project can readily be applied to other areas and can be used for a wide range of rock penetration methods, ranging from smaller wellbores to large tunnels. Another area that has a direct relevance and a solid industry base in Norway is drilling tunnels for small-scale hydroelectric plants and grid for renewable energy transport.

The industrial consortium covers the value chain for geothermal drilling:

- Several Norwegian and European materials and drilling tool suppliers: Atlas Copco, Lyng Drilling (Schlumberger), NOV, Robit, Varel International (Sandvik)

- Energy companies: ENEL Green Power, St1

- "Smaller" Norwegian companies: Badger Explorer, Norhard, Rock Energy, Tomax and Zaptec.

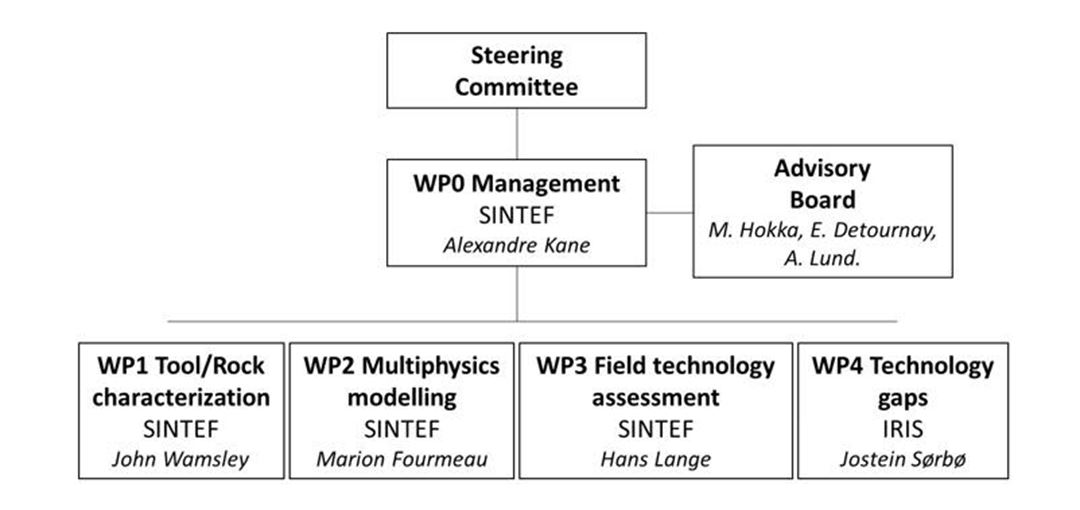

The industrial partners contribute to the research activities providing 23% of the total budget and in-kind contributions (such as data, material or experimental facilities). In addition to the Norwegian research partners SINTEF, IRIS and NTNU, international research partners such as University of Minnesota (USA) and University of Tampere (Finland) are strongly involved in the research activities. During KPN INNO-Drill, one PhD and one PostDoc position will be funded and supervised by the research partners.

INNO-Drill is a 4-years Knowledge Building Project performing from 2016 to end of 2019, granted within the ENERGIX program of The Research Council of Norway, with total budget of 24 MNOK.

KPN INNO-Drill was built upon research activities developed during KPN NEXT-Drill, ended in 2015 ( NEXT-Drill page)