Global Impact- Gemini Center

In the Gemini Center 'Equitable Partnerships for Global Impact', SINTEF and NTNU have joined together to better address the 2030 Sustainable Development Agenda’s imperative of “Leaving no one behind”.

In the Gemini Center 'Equitable Partnerships for Global Impact', SINTEF and NTNU have joined together to better address the 2030 Sustainable Development Agenda’s imperative of “Leaving no one behind”.

A transdisciplinary project addressing the deep energy renovation of heritage buildings.

Minimizing uncertainty, ensuring sustainable hydropower production with a focus on extreme events in a future climate.

Framework for smart condition reassessment of Reclaimed Timber to eXtend the service life of long-lived wood products using non-destructive testing and automated data postprocessing

DYNAPORT will develop new optimization and coordination tools for ports and ships that reduce the ship's fuel consumption and increases port efficiency with at least 10% and ensure implementation by relying on internationally accepted information...

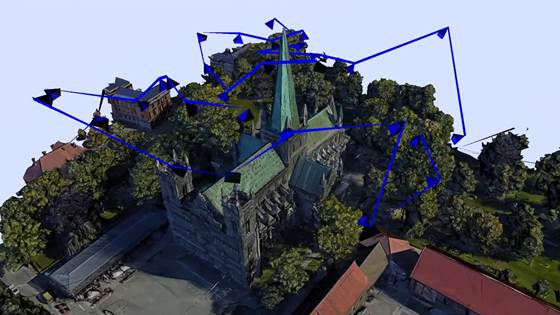

In Airspector we are building tools for planning and simulating aerial inspection missions using autonomous drones. Our goal is to make it simple to plan efficient and safe drone paths to inspect any 3D model, to inspect any type of infrastructure in...

The APOLLO project is set to forge a circular system, intertwining traditional recycling practices with future manufacturing and recycling processes for Photovoltaic (PV) waste modules.

DigiBatt will slingshot the European battery industry forward by using advanced digital technology to make battery testing faster, cheaper and more accurate. We will develop novel digital approaches to extract more value from fewer tests. This will...

ELOXYCHEM will establish a electrochemical oxidation process that will replace existing thermochemical processes that are reliant on imported materials such as nitric acid and imported fossil-fuels.

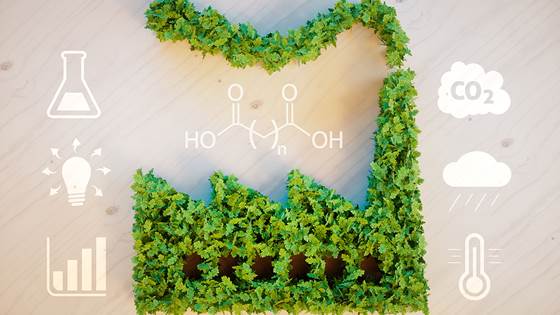

Industry is responsible for a large part of the global energy consumption and emissions. To help meet energy demands and reduce climate change, Extreme Efficiency aims to make industrial processes more energy efficient.

IPN Freki aims to develop a data-driven process for the pre-qualification of frequency containment reserves (FCR).

This project aims to develop digital solutions that advance geological heat storage as an eco-friendly, scalable energy storage method, reducing energy demand and supporting the green energy transition.