Sub goals:

- Provide a review of the major weaknesses and uncertainties of the today's concepts for high power converters for deepwater applications.

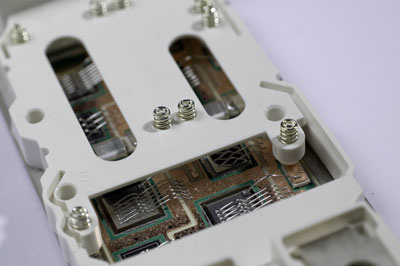

- Clarify the operability of pressurized (200 bar) power circuit and driver circuit components through cooperation with manufacturers and by testing components in laboratory.

- Demonstrate possible new design solutions by use of pressurized power circuits and transistor driver circuits

- Provide methodologies and guidelines for qualified pressurized converter designs, including support for upgrading of specifications

- Accomplish a PhD degree within liquid dielectrica for pressurized power electronics

Benefits by exposing power circuit to ambient pressure

- Weight and volume of pressure chamber significantly reduced

- Electric power penetrators significantly reduced due to reduced numbers of connections between pressure compensated and 1 bar chambers

- Enables less complex and more reliable cooling system (e.g. direct conductive cooling, eliminating pumps, heat exchanger etc.)

- Reduced cost for subsea VSD A design which take advantages of the benefits listed above will be simpler and reduce the costs for subsea VSD

- Increased reliability A simpler design with less components will probably result in higher reliability.

Industrial relevance

- Future oil and gas development projects call for reliable power electronics:

- Small and medium power (0.1-100 kW) supplies for electronics, actuators etc.

- High power converters (0.1-100MW) for variable speed drives.

- Ongoing projects, e.g. Ormen Lange, have revealed that frequency converter is the Achilles' heel when it comes to obtaining reliable and feasible solutions.

- The challenges are related to obtaining satisfactory reliability figures and obtaining manageable size, weight and costs.

- One goal for this project was to prove that critical components can operate with satisfactory reliability in high pressure environment

- This will open up for the realization of quite new concepts for realizing more manageable converters, also including more confidence when it comes to reliability

- The results from the project will be accessible for the supplier industry joining the project.

- Especially will the results from the work-package be available for manufacturers of power electronic converters joining the project