Industrial production of aluminium is by electrochemical reduction in a fluoride based molten salt with dissolved alumina at 960 °C. The materials challenges in the process are extensive, including many different chemical and electrochemical mechanisms.

Carbon anodes are important for the electrochemical process as they are consumed in the electrochemical reaction, mainly through formation of CO2. For anodes, among others, it is important to avoid soot formation as this affects the electrolyte negatively and cause excess carbon consumption. Further, the anodes should have low anodic overpotential to reduce energy consumption. Materials properties important for good anode performance are subject to investigations in CaRMa.

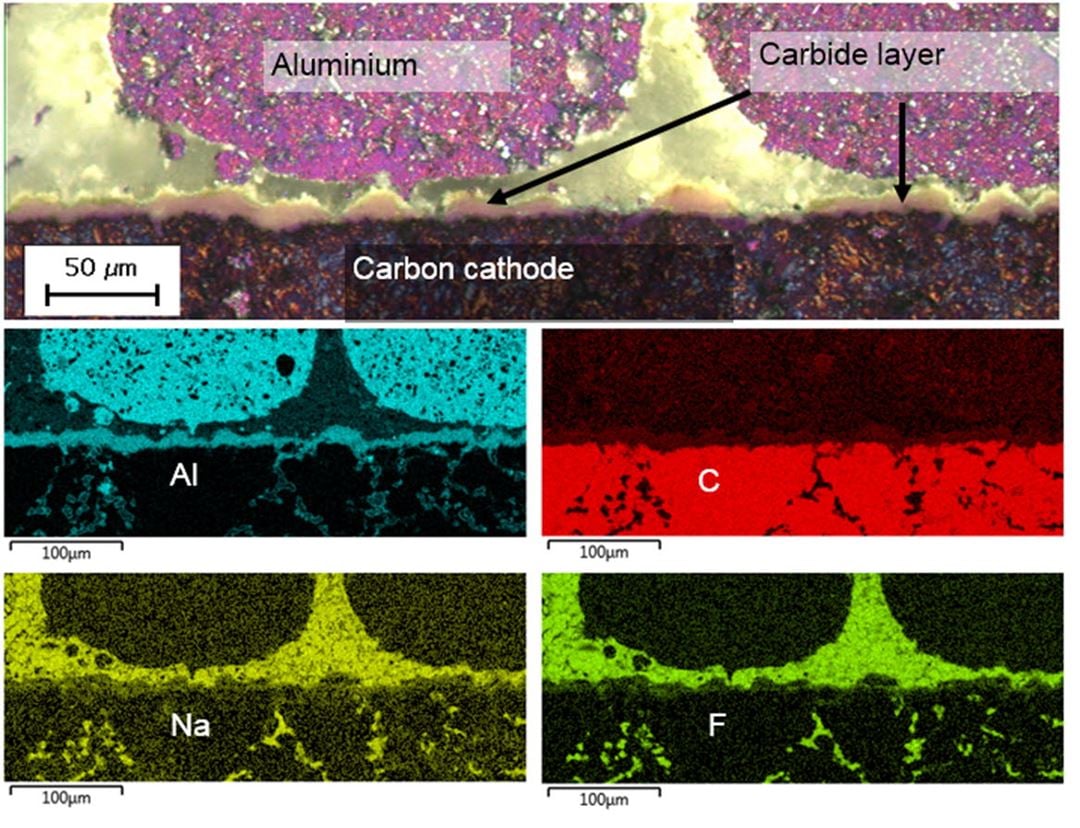

Graphite cathodes are in principle inert in the electrochemical process; however, conditions in the cell cause significant erosion in some areas of the cathode. CaRMA focus on understanding conditions and materials properties related to reduced lifetime of the cathodes.

As the industry are striving towards lower energy consumption in the electrolysis cell, excess heat is also reduced. This requires better insulation of the cell causing the insulation materials to be exposed to more severe chemical and thermal exposure. Materials design and structural mechanisms important for sustained integrity in the cell environments are studied in CaRMa.

The carbon anodes used in aluminium electrolysis are produced in separate baking furnaces. The green anodes are made of petroleum coke, coal tar pitch and anode butts recycled from the cell. During baking the refractories in the baking furnace are subject both to chemical exposure and thermal cycling between room temperature and 1200 °C. . Conditions that affect the lifetime of the refractory materials are studied in CaRMa.

CaRMa is a joint competence building project between SINTEF and NTNU, including the education of four PhD candidates. The project is financed by the Research Council of Norway in cooperation with Alcoa, Elkem, Hydro and Skamol. The goal of the project is better fundamental understanding of material properties needed for prolonged lifetime, reduced energy consumption and lower production costs for aluminium.