The key feature of this technology is the way in which a mixture of elemental powders is accurately and directly fed into the laser's focal point, heated by the laser beam, and deposited on a substrate in the form of a melt pool, which finally solidifies to create a unique fully-dense alloy button with precise stoichiometry.

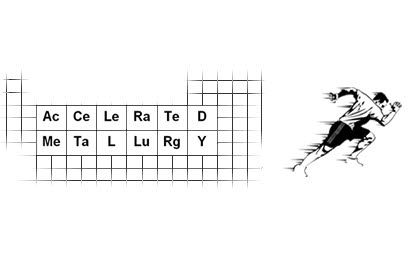

In contrast to the traditional slow trial-and-error approach, the Accelerated Metallurgy project advocates the accelerated discovery and optimisation of higher-performance alloy formulations using combinatorial principles. By rapidly and automatically synthesising large numbers of compositionally-varying alloy samples (less than 60 seconds per sample) followed by high-throughput testing of their structures and properties, it is now conceivable to intelligently screen large compositional landscapes in search of special alloys that have, up to now, remained unexplored. This robotic alloy synthesis is 1000 times faster than conventional manual methods. Once produced, these discrete mm-sized samples are submitted to a range of automated, standardised tests that will measure chemical, physical and mechanical properties. The vast amount of information will be recorded in a "Virtual Alloy Library" and coupled with computer codes such as neural network models, in order to extract and map out the key trends linking process, composition, structure and properties.

|

| Potensielle anvendelser av ACCMET – basert på de industrielle partnerene som deltar i prosjektet |

The most promising alloy formulations will be further tested, patented and exploited by the 20 end-users. Industrial interests include:

- New lightweight fuel-saving alloys (<4.5 g/cm3) for aerospace and automotive applications.

- New higher-temperature alloys (stable>1000 °C) for rockets, gas turbines, jet-engines, nuclear fusion.

- New high-Tc superconductor alloys (>30K) that can be wire-drawn for electrical applications.

- New high-ZT thermoelectric alloys for converting waste heat directly into electricity.

- New magnetic and magnetocaloric alloys for motors and refrigeration.

- New phase-change alloys for high-density memory storage.

The accelerated discovery of these alloy formulations will have a very high impact on society.

- The ACCMET partnership gathers 29 entities coming from 10European countries. The project is hosted by European Space Agency. 14 ACCMET partners are companies: Rolls Royce Plc, Centro Ricerche Fiat Scpa, Avio S.P.A ,Airbus group (EADS Deutschland Gmbh), Bruker EAS Gmbh, United Kingdom Atomic Energy Authority, Ocas - Onderzoekscentrum Voor Aanwending Van Staal N.V. (Arcelor), Norsk Titanium Components AS, Johnson Matthey Plc., Aktsiaselts Silmet , Tls Technik Gmbh & Co. Spezialpulver, Renishaw plc, Granta Design Ltd, Avantys Engineering Gmbh. This pool of industrials is supported by 9 academic partners (Cardiff University, Universitaet Ulm, Universita Degli Studi Di Torino, Universite De Rouen, Danmarks Tekniske Universitet (Riso), The University of Sheffield, The University of Cambridge, Akademia Gorniczo-Hutnicza Im. Stanislawa Staszica W Krakowie and The University of Birmingham) and 5 experienced research organizations (Stiftelsen SINTEF , Flamac, Fraunhofer-Gesellschaft Zur Foerderung Der Angewandten Forschung E.V , Installation Europeenne De Rayonnement Synchrotron (ESRF), Institut Max Von Laue - Paul Langevin (ILL).

- ACCMET is a project co-funded by the 7th Framework Programme of the European Commission, coordinated by the European Space Agency. The total budget is 22.0 Mio €, and the area of activity of the project is FP7-NMP-2010-LARGE-4

Example publications from project:

- García-Cañadas, J. & Min, G. (2014). Multifunctional probes for high-throughput measurement of Seebeck coefficient and electrical conductivity at room temp. Review of Scientific Instruments (vol. 85, 043906, p. 1-4). AIP Publishing / doi: 10.1063/1.4871553

- Caraballo, I.T., Nava, E.G. & Diaz-del-Castillo, P.R. (2014). Discovery of new materials and heat treatments: Accelerated Metallurgy and the case of ferrous and magnesium alloys. Materials Science Forum (vol. 783-786, p. 2188-2193). Elsevier / http://www.scientific.net/MSF.783-786.2188

- Jasiewicz, K., Cieslak, J., Kaprzyk, S. & Tobola, J. (2015). Relative crystal stability of AlxFeNiCrCo high entropy alloys from XRD analysis and formation energy calulation. Journal of Alloys and Compounds (vol. 648 307). Elsevier / doi:10.1016/j.jallcom.2015.06.260

- Mackie, A.J., Hatton, G.D., Hamilton, H.G.C., Dean & Goodall, R. (2016). Carbon uptake in Spark Plasma Sintering (SPS) processed Sm(Co, Fe, Cu, Zr)z. Materials Letters (vol. 171, p. 14-17). Elsevier / doi:10.1016/j.matlet.2016.02.049

- Cornide, J., Calvo-Dahlborg, M., Chambreland, S., Asensio Dominguez, L., Leong, Z., Dahlborg, U., Cunliffe, A., Goodall, R. & Todd, I. (2015). Combined Atom Probe Tomography and TEM investigations of CoCrFeNi, CoCrFeNi-Pdx (x=0.5, 10, 1.5) and CoCrFeNi-Sn. Acta Physica Polonica (vol. A128, p. 557-560). Acta Physica Polonica / http://dx.doi.org/10.12693/APhysPolA.128.557