Preparation and characterization of porous materials

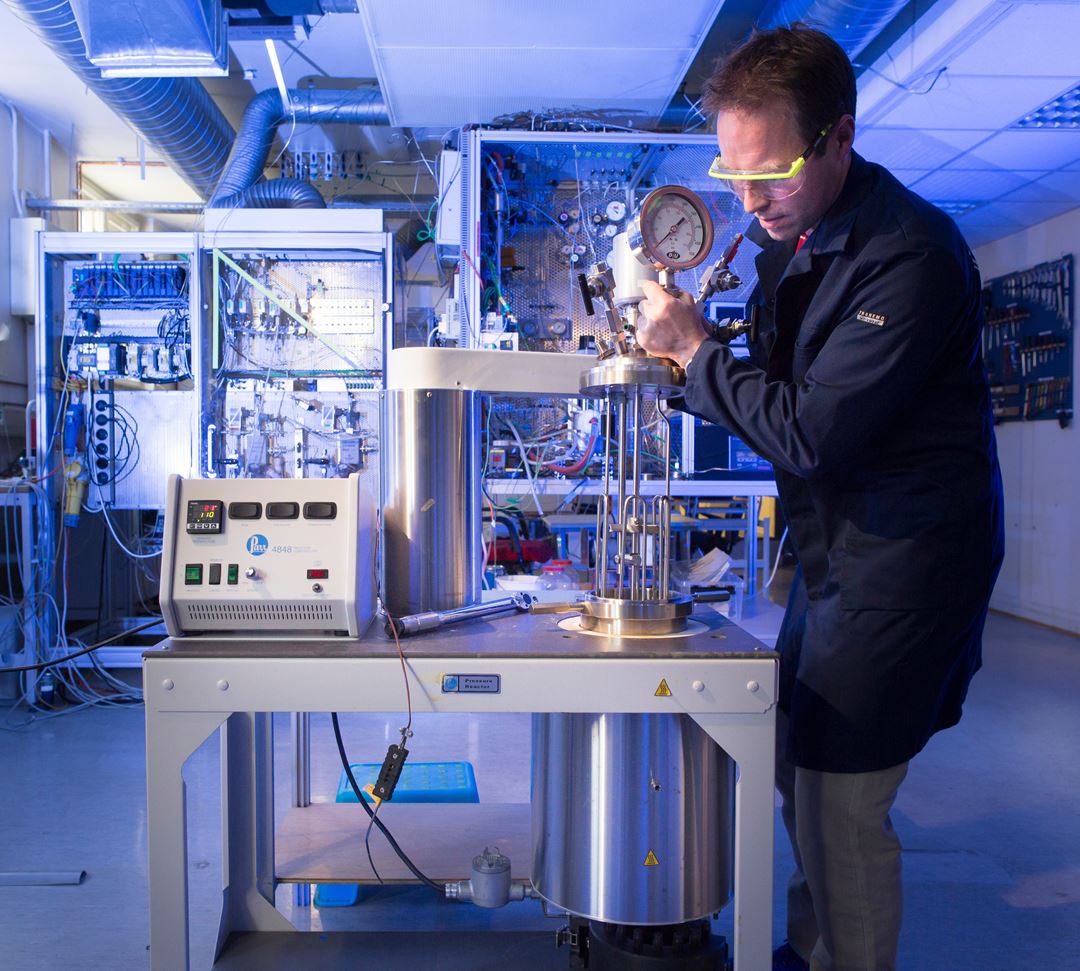

Porous materials such as zeolites, metal-organic framework (MOF) and silica (MCM-41, SBA-15, etc.) are prepared either in the autoclave under hydrothermal conditions or in solution in more moderate conditions. Batch synthesis is commonly used, but also continuous synthesis is a method suitable for such materials. Work on continuous synthesis using long tubular reactors or specially designed advanced flow reactors produced by 3D printing are in progress. Such processes can easily be scaled up by parallelization and provides in principle a cleaner product (less by-products) and higher productivity.

Characterization of porous materials is mostly done by powder X-ray diffraction (XRD); identification and structure analysis, and gas adsorption experiments (N2/Ar adsorption; BET surface area, pore size distribution, etc.)

Applications of porous materials

Micro- and meso-porous materials typically have specific surface area from200 to 6000 m2/g! High surface area materials are used in various separation technology based on adsorption onto surfaces and within catalysis. SINTEF has the expertise to perform the following processes:

- Gas phase separation by pressure swing adsorption (PSA) or temperature swing adsorption (TSA))

- Heat-pumps and chillers for instruments and computers using adsorption/desorption cycles of water or other adsorbates

- Separation in solution (as the solid phase in chromatographic processes or as selective adsorbent to remove impurities).

- Microporous zeolites are used extensively in catalysis (acid catalysis (FCC - fluid catalytic cracking, alkylation, reforming, etc.)