In the future it will quite literally be a heavier task to bring offshore oil ashore than it has been until now.

All over the world, many of the fields that have yet to be developed are full of heavy oils; pitch-black liquids that flow more slowly than the oil that we produce today.

Much of this unexploited oil lies beneath great water depths. Many of the fields lie in the far north, surrounded by ice from which both workers and installations will have to be protected.

Multiphase transport

In such environments, the choice of production technique will often fall on subsea technology, which in turn means multiphase transport of oil, gas and water in a single pipeline on the seabed, directly from the well to the shore or to a platform with spare capacity.

Thousands of subsea pipeline systems are already transporting light oils.

But what will it cost to install pipeline systems that are sufficiently robust to ensure that heavy oils are always brought safely ashore? Rising up steep seabed slopes from great depths?

At the biggest flow laboratory in the world, SINTEF is gathering measurements that will give us the answers.

|

| With the aid of this retrofitted measurement unit, SINTEF’s Multiphase Laboratory has opened a new window on the phenomenon of multiphase flow in oil and gas pipeline transportation. Photo: SINTEF / Christian Brekken |

Reduced financial risk

According to the research group, the data provide important new knowledge about how heavy oil behaves in multiphase pipelines. This may turn out to be of great importance for the fate of a large number of hydrocarbon discoveries.

“These measurements reduce the economic uncertainty involved in estimating the cost of bringing heavy oils ashore,” confirms Jo Jernsletten, a senior process engineer with Norske Shell.

According to Jernsletten, continuing uncertainty in this area would have two consequences: many heavy-oil projects would have been designated as “over-robust” at the drawing-board stage, and would therefore have been declared to be unprofitable.

“Estimates based on these new measurements will change all this. In many cases, they are likely to open up the possibility of developing fields that would otherwise have been abandoned,” says the Norske Shell expert.

Pumping needed

Norske Shell is one of four oil companies that have financed the measurement technology project at SINTEF’s Multiphase Laboratory.

Jernsletten explains that the results of the measurements will be used to update current multiphase transport models, and that this will bring one important benefit: more reliable prognoses of the size of the pressure drop in pipelines that carry slowly flowing oil as the distance from the well increases.

Pressure drop prognoses show in their turn how much oil can be transported via a planned pipeline, before the field developer would need to install expensive subsea pumping equipment.

Prize-winning invention

Scientists at SINTEF’s Multiphase Flow Laboratory have been given several reasons to smile during the past few months.

Together with the Institute for Energy Technology (IFE), SINTEF has been given much of the honour for making this type of seabed transport possible. The technology that emerged from their pioneering efforts was recently identified by the Norwegian daily Aftenposten as Norway’s most important invention since 1980.

This was followed by the new measurement results, which have been highly praised by the offshore sector. Senior project manager Christian Brekken makes it quite clear that this has been a heart-warming response.

“You are contributing to the utilisation of hydrocarbon resources that the world would otherwise have had to do without. But a lot of people who want to save our climate might have been just as happy if petroleum discoveries had to be left in the ground?”

“Even in the greenest scenarios for the future, we will still be using a great deal of oil and gas in 2050. The energy requirements of the growing global population cannot be met without hydrocarbons. This makes it all the more important to bring petroleum resources safely and efficiently ashore from the difficult reservoirs that are waiting to be exploited. Multiphase research can probably help to prevent both people and industry from suffering energy crises.”

|

|

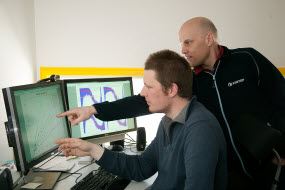

Research scientist Ivar Eskerud Smith (left) and project manager Christian Brekken discuss the results of this unique measurement project. Photo: SINTEF / Gry Karin Stimo |

Detailed flow images

Many of the flow measurements performed in SINTEF’s full-scale multiphase laboratory are being made with the help of gamma radiation.

Traditional measurements gave mean values of the volumes of gas and liquids that flowed through the 1000 metre-long pipe-loop. This was good enough as long as we were dealing with light oil and using relatively coarse mathematical models,” explains Brekken.

The measurements in the new tests are made using a type of equipment that goes under the name of “'traversing gamma densitometer'”.

A beam of gamma rays is transmitted horizontally through the pipeline, and the change in beam density is measured on the opposite side. The source of the beam and the detector are then moved with millimetre accuracy in the vertical direction (i.e. 'traversing') while the measurement is made. This technique provides a more detailed picture of the flow in selected cross-sections of the pipeline.

According to Brekken, SINTEF is the only research centre in the world that operates such an industrial-scale instrument package for pipelines.

“So have you already reached your goal, or are more measurements still needed?”

“We are going to make many more measurements. Not least, we are planning a collaboration with IFE, since it uses a related measurement technique. Each of these methods has its own strengths and weaknesses,” says Brekken.

“Together, we want to employ a number of different measurement techniques under a wide range of different conditions. Cooperation of this sort will enable the petroleum industry to verify the validity of the coming generation of models of multiphase transport.

by Svein Tønseth

|

Multiphase technology

|