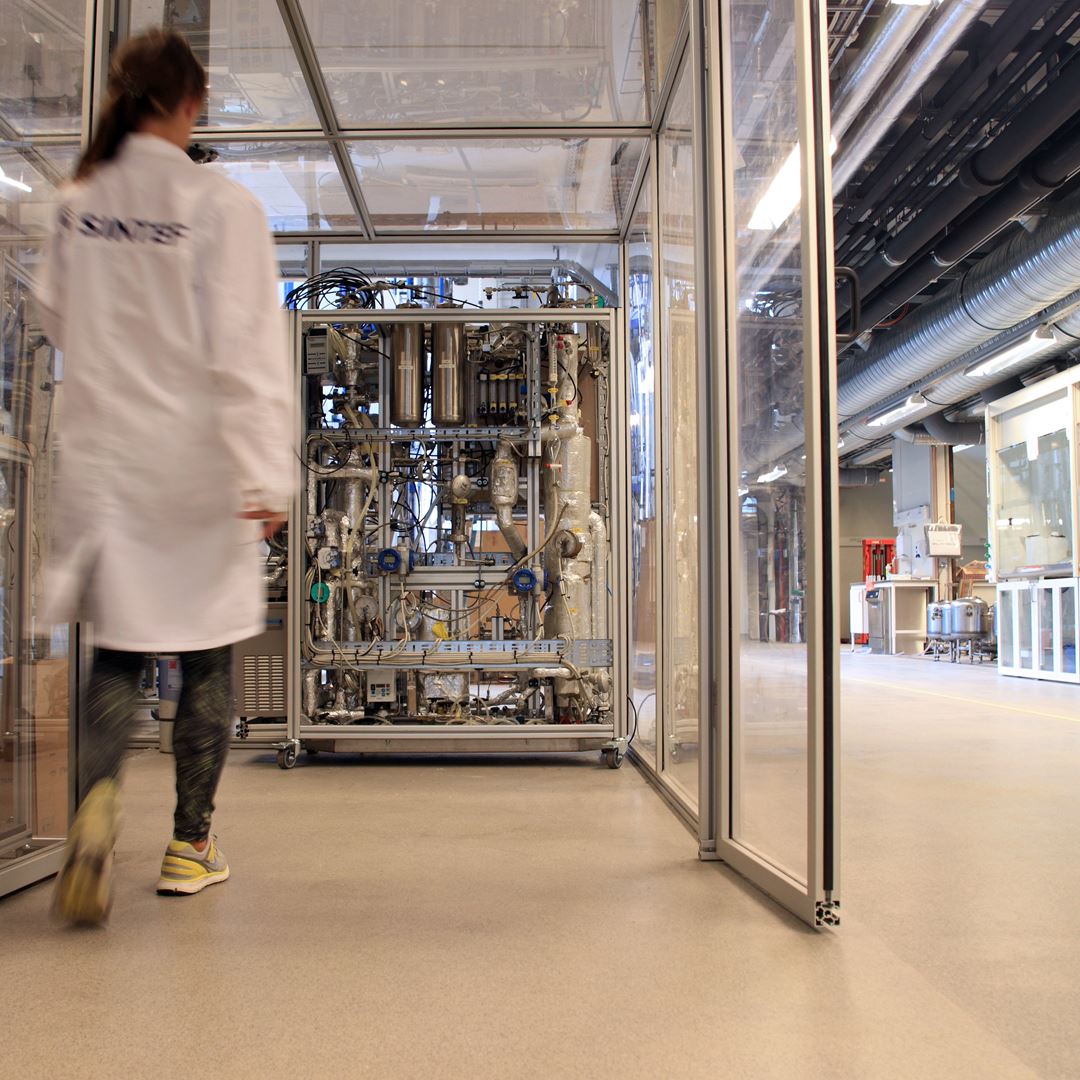

We at SINTEF have the experience and capability to build test equipment from small scale units to larger pilot plant. The CO2Lab at Tiller is an example of this. The design of equipment is carefully chosen to facilitate instrumentation and data sampling.

We combine the results from our own experiments, data from industry, and data from the literature to build models of the processes. The model complexity is chosen to the sufficient level for describing the phenomena under study, and the models range from unit operation models with detailed description of thermodynamics, reaction kinetics and flow properties to simpler models for the description of overall process performance.

SINTEF has extensive experience and capabilities within

- making use of experimental data for building models and correlations for thermodynamics, reaction kinetics and mass transport.

- validation of models against experimental data.

- modelling of mass and energy balances for unit operations and complete chemical process plants.

- making tailor made models of unit operations and process plants for purposes such as design studies, optimization and advanced process control applications.

- modelling and simulation of dynamics in process plants.

- analysis, benchmarking and techno- economical evaluations

- proof of concept studies.

- software design and development for simulation, data handling and analysis.