Our customers are manufacturers of ceramics (Hotel China, pottery, refractory materials, glass, clay bricks, advanced ceramics etc.), or businesses that are looking for ceramic materials with special properties. The materials may be obtained from raw materials specified by the customer, or SINTEF can develop special raw materials in the form of e.g. powder.

Our areas of expertise

Glass, glass ceramics, structural ceramics, composites, high temperature sealing, porcelain, porcelain glaze tile and expanded clay.

The method we use

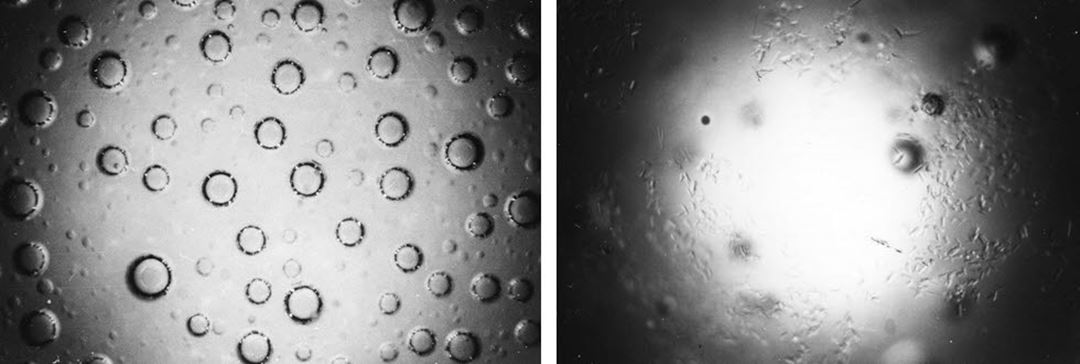

We manufacture prototype materials of glass or ceramic in our laboratories. Samples of raw material in powder form is first compressed then later heated up to 1800°C (sintered). Further, we test the samples' physical properties (density, porosity, thermal expansion, electrical conductivity, mechanical strength, microstructure, crystalline phases and glass phase). Through experiments of various material compositions, we develop processes for the production of ceramics and glass - with desired properties.

Typical tasks we perform

- Characterisation of materials at high temperatures (thermal expansion, thermal conductivity, electrical conductivity, modulus of elasticity, maximum use temperature)

- Characterization of microstructures (mineral phases and their composition, crystal size, crystal shape, porosity)

- Development of glass/glass ceramics for high temperature gaskets, typical seals for high temperature fuel cells or membrane reactors.

- Finding cause of failure e.g. during the porcelain production process, and finding a solution to the problems

- Develop ceramic materials based on mineral excavation residues

- Optimizing properties of ceramic materials through changes in raw material composition/process parameters