Dynamic full scale testing for qualification of flexible risers, power cables and umbilicals can be performed as well as tests of unique set-up. Small scale testing can be performed to obtain material data and material coefficients for use in numerical analysis and full scale testing.

The structural laboratory is operated by SINTEF Ocean in cooperation with Norwegian University of Science and Technology, Dept. of Marine Structures. The laboratory is certified to ISO 9001.

Main installations

Two test frames have been built specifically for full scale testing of flexible risers, loading hoses, umbilicals and power cables. The test frames can provide a combi-nation of axial tension and bending loads. A third permanent test frame is designed for combined axial and compression testing of power cables and umbilicals. An example of a test performed in this frame is shown further down on the page.

The requirements for instrumentation, accuracy of loading and quality of non-destructive examinations have increased significantly during the last few years, and new methods have been applied to improve the quality of data obtained. Radiography and gamma-ray, acoustic emission, acceleration measurements, strain gauge measurements of tensile armour wires and curvature measurements along the bend stiffener region have become a part of a standard full-scale test.

A range of servohydraulic actuators for static and dynamic testing are available in the laboratory. Combined with a modular frame system, temporary test frames for special purpose testing can be assembled in an efficient manner. These are typically used for mid-scale tests and can accommodate specimens and structural models of a wide range of shapes and sizes, under uniaxial or multiaxial loading, and with load capacities up to 4000 kN.

Small scale test facilities are available for structural testing of components. A particular focus has been on tests relevant for flexible pipes, umbilicals and power cable components, such as tensile or pressure armour wires, conductors, PE sheaths and tape layers. Small scale testing can be performed to obtain material data and material coefficients to be used in numerical analysis and full scale testing. This includes testing to define SN curves under different environmental conditions, friction and wear testing, but also other types of mechanical testing.

Control and logging equipment includes several computerized systems for multi-actuator control, fatigue load simulation, as well as data logging with on-line reduction and analysis.

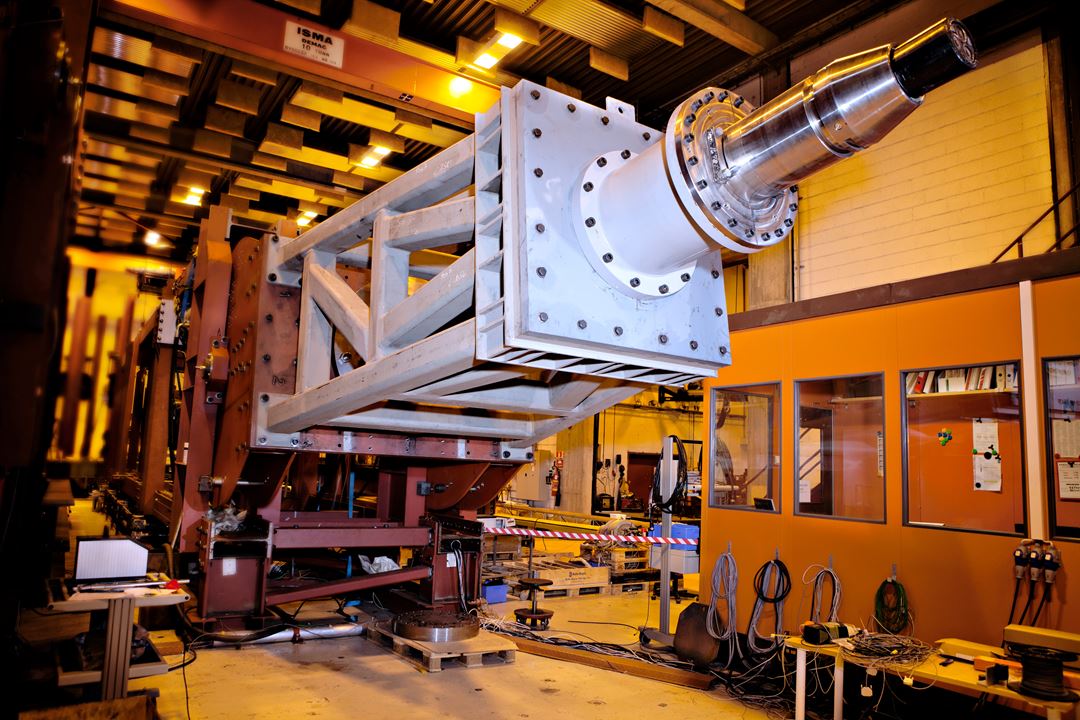

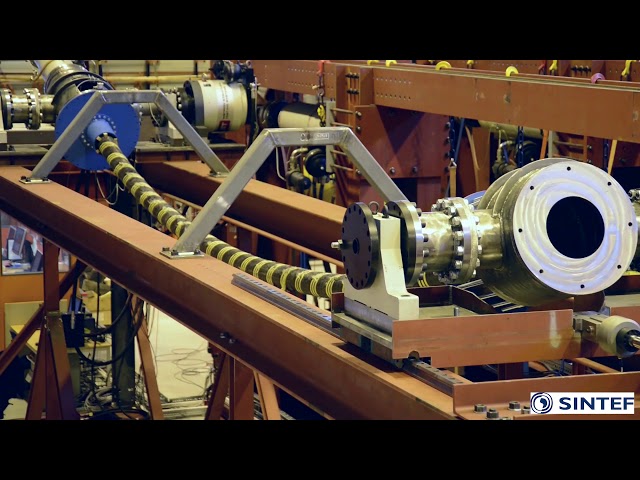

Full-scale laboratory test of a dynamic subsea power cable from NKT HV Cables subjected to compression and bending.

- Umbilicals and power cables are usually installed at a relatively low level of tension. The cables may be subjected to compressive axial loads, usually from vessel heave during installation and/or in service. Any compressive loads involves a risk of local buckling of components and possibly overall torsion instabilities of the cable.

- SINTEF Ocean has built a separate test rig tailor made for full-scale testing of power cables and umbilicals subjected to compressive loads. The tests are designed to simulate installation and/or operational conditions in the laboratory.