|

Silicon/Polymer integration

microBUILDER has developed a standard fluidic interface slide for combination of silicon/glass chips and plastic slides and for integration into the ThinXXS microfluidic construction kit. Fluidic silicon/glass chips-to-world connections are provided. In addition, the new fluidic interface slide gives flexibility of integrating silicon/glass chips with polymer chips, pumps etc. The new standard simplifies the use of silicon/glass for fluidic applications. Combining silicon/glass sensors and actuators with polymer chips enables the customer to make use of both the excellent electrical and mechanical properties of silicon and the low prices of polymers.

Silicon/glass and polymer integration, step by step:

The three industrial manufacturers in microBUILDER, SensoNor Technologies, TRONICS Microsystems and thinXXS offer low-cost manufacturing of silicon/glass and plastics components. The silicon/glass manufacturing processes are available as an ordinary service or as a Multi Project Wafer (MPW) Service. The polymer manufacturing processes for plastic components are available as an ordinary service. Mixed tecnology or so called add-on processes are also available from the microBUILDER partners in order to increase the functionality of the devices and to enable the integration into mixed techology systems.

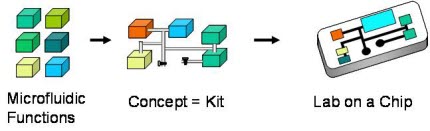

Microfluidic Construction KitThe microfluidic construction kit offers the opportunity to develop integrated microfluidic chips, so called lab-on-chips, in an easier, faster and less costly fashion than before: Various standard functions, such as mixing, splitting or pumping are provided on single microfluidic slides. All slides can be combined in different configurations to represent various fluidic designs.

The fluid interfaces can be easily connected and disconnected, possess low dead volumes and are leakage tight. The complete assembly of the microfluidics system can be done without specific tools or know-how. Once the design of a fluid network has been optimized on the modular system level, it can be transferred into an integrated, compact and cost-efficient device. Since mass production processes are used to manufacture the plastic slides, an easy transfer from the modular to the integrated system is achieved. Silicon sensors can be easily integrated in plastic modules to provide a broad range of standard functionalities. |

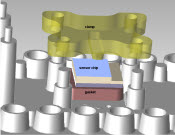

Fluidic interface slide

Assembly of a slicon sensor into the polymeric inteface slide

Dimensions and placement of holes on the bottom glass

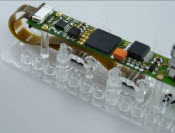

The integration slide with flow sensors and electronincs read-out

Bottom view of integration slide with two flow sensor and electronics readout | ||||||||||||||||||||||||||||||||||||||||